A thinning-free film side millet drill

A technology that avoids thinning seedlings and seed drills, and is applied in the direction of sowing seeders, seeder parts, fertilizers, and seeding equipment. slow, save seed consumption, and eliminate the effect of thinning operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

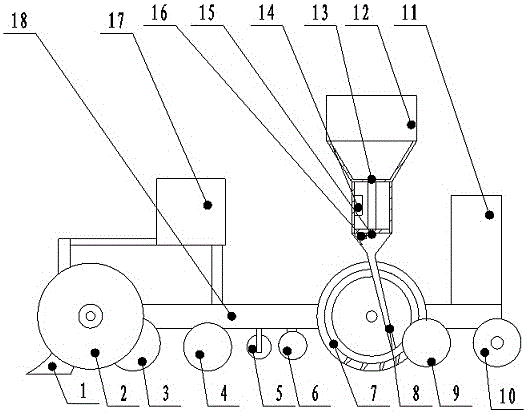

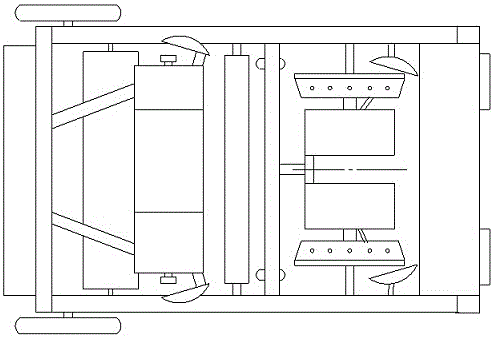

[0027] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the light and simple thinning-free film side millet drill includes power transmission device (tractor), plow 1, walking wheel 2, film hanging roller 3, hook soil plate 4, film spreading roller 5, film pressing wheel 6, grain sowing Disc 7, grain conveying pipe 8, covering soil disc 9, pressing roller 10, water tank 11, grain hopper 12, fertilizer hopper 17 form.

[0028] Plow 1, walking wheel 2, film hanging roller 3, hook soil plate 4, film spreading roller 5, film pressing wheel 6, grain sowing plate 7, grain conveying pipe 8, soil covering plate 9, pressing roller 10, water tank 11, grain hopper 12 And fertilizer hopper 17 is all fixedly installed together with frame 18. Frame 18 is connected with tractor.

[0029] The frame adopts metal tubes welded into a frame structure.

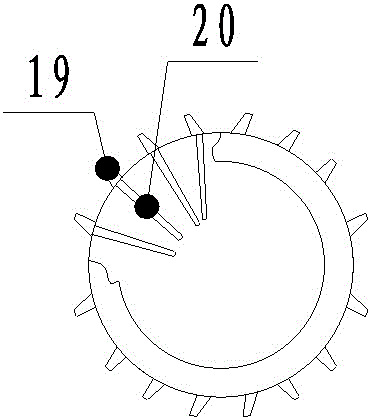

[0030] The laminating mechanism is formed by the film-hanging roller 3, the hook soil plate 4, the film-expanding roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com