Dual-wavelength laser annealing device and method thereof

A dual-wavelength laser and annealing device technology, used in laser welding equipment, electrical components, circuits, etc., can solve the problems of short wavelength of 515nm laser, low crystal absorption energy, low activation rate, etc., and achieve excellent processing effect and annealing uniformity. High, improve the effect of activation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

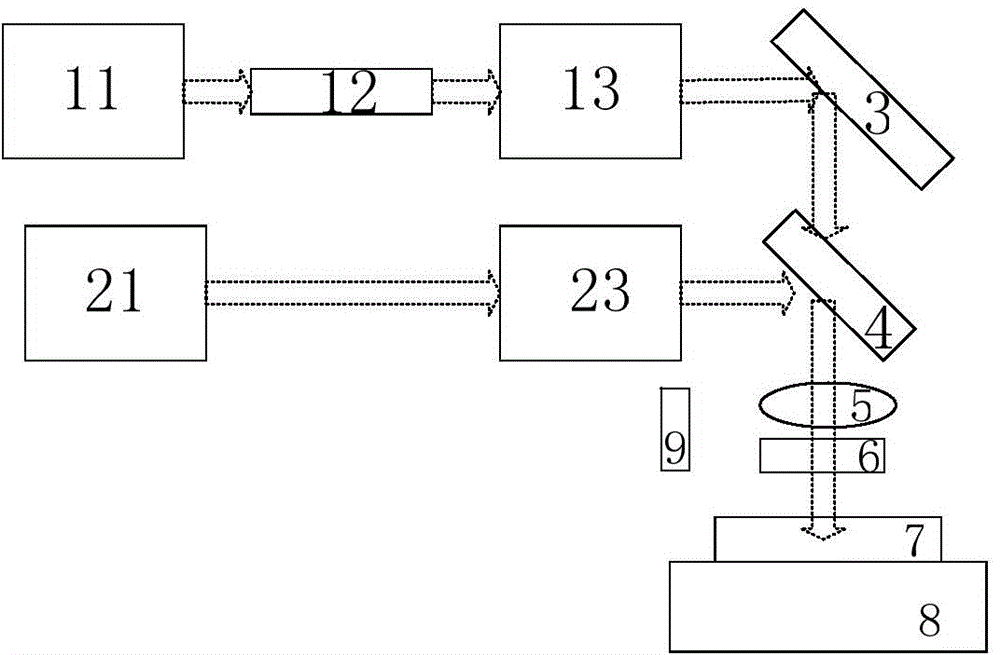

[0019] Such as figure 1 As shown, the dual-wavelength laser annealing device includes a green laser 11 and an infrared laser 21. On the output optical path of the green laser 11, a beam expander module 12, a green strip-shaped spot shaping module 13 and a green 45-degree reflector 3 are arranged in sequence. , the infrared strip spot shaping module 23 and the infrared 45-degree reflector 4 are arranged in sequence on the output light path of the infrared laser 21, the green light 45-degree reflector 3 and the infrared 45-degree reflector 4 can be a beam splitter, and the infrared laser light passes through the Reflecting mirror, combined with the reflected green laser beam, then output to the beam combining projection focusing mirror 5 at the rear end, the output optical path of the beam combining projection focusing mirror 5 is provided with an iris 6, and the output end of the iris 6 is facing Processing platform 8.

[0020] Wherein, the green laser 11 is a Q-switched pulse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com