Drying machine

A drying machine and balancing machine technology, which is applied in the drying machine, drying, local stirring and drying machine and other directions, can solve the problems of unguaranteed drying quality, easily baked bad food, complicated structure and layout, etc. The moisture exchange is sufficient and fast, the heat and moisture exchange effect is good, and the baking quality is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the drawings:

[0021] Under the suction force of the internal fan, the fresh cold air from the outside directly exchanges heat with the heater through the air inlet and becomes dry hot air, and then exchanges heat with the objects to be dried in the working area before being discharged from the body , And the objects to be dried in the working area will gradually evaporate and dry the moisture under the action of dry hot air. Since the evaporation of moisture in the dried material needs to absorb and consume heat energy, the main problem is that the heater is exposed to heat and the casing heat is wasteful. The steam pressure fluctuation has a great impact on energy consumption. The present invention avoids heat insulation in the enclosed space. Heat energy is lost and energy can be saved.

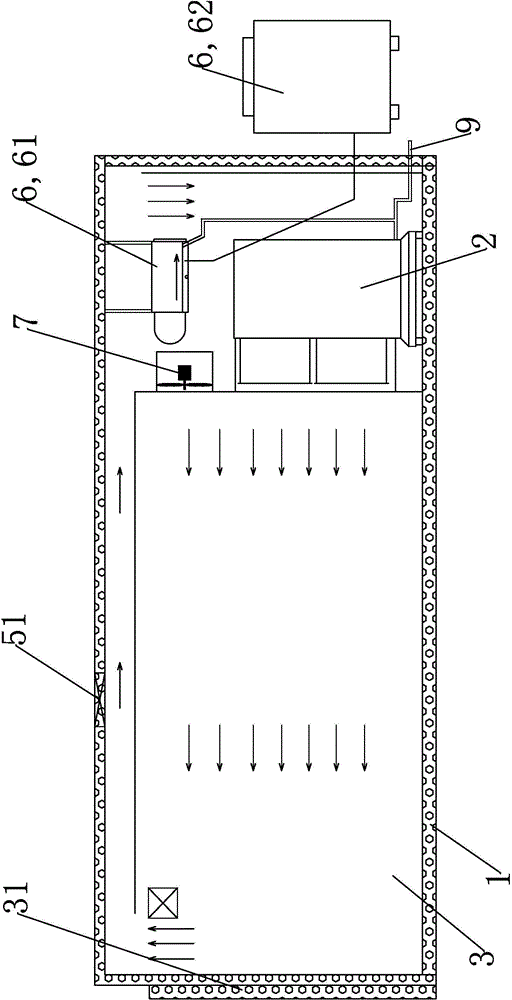

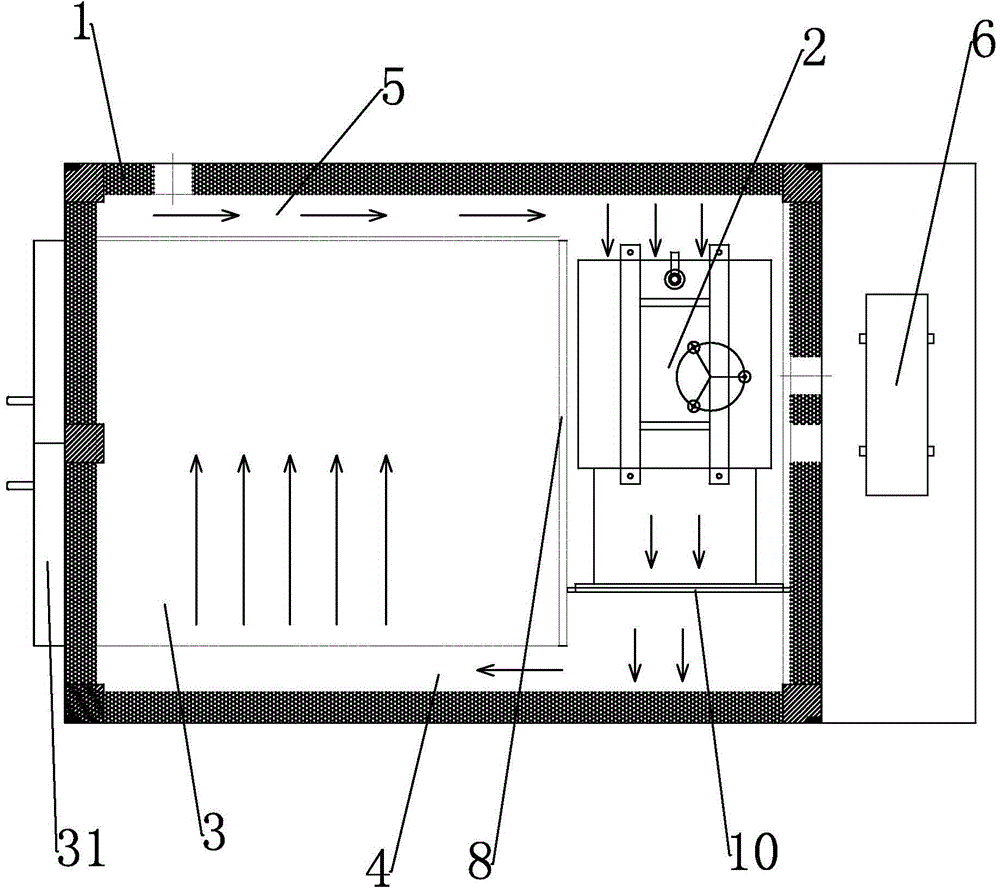

[0022] Such as figure 1 , A dryer, including a box body 1, a dryer body 2 for dehumidification and heating i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com