Multi-condition design method for multi-phase mixed transportation axial flow pump impeller

A design method and technology for an axial flow pump, which is applied to the components, pumps, and pump components of a pumping device for elastic fluids, which can solve the problem of axial flow pump head, decrease in efficiency, increase energy consumption, and less impeller design methods. and other problems, to achieve the effect of high efficiency, excellent hydraulic performance and high efficiency requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

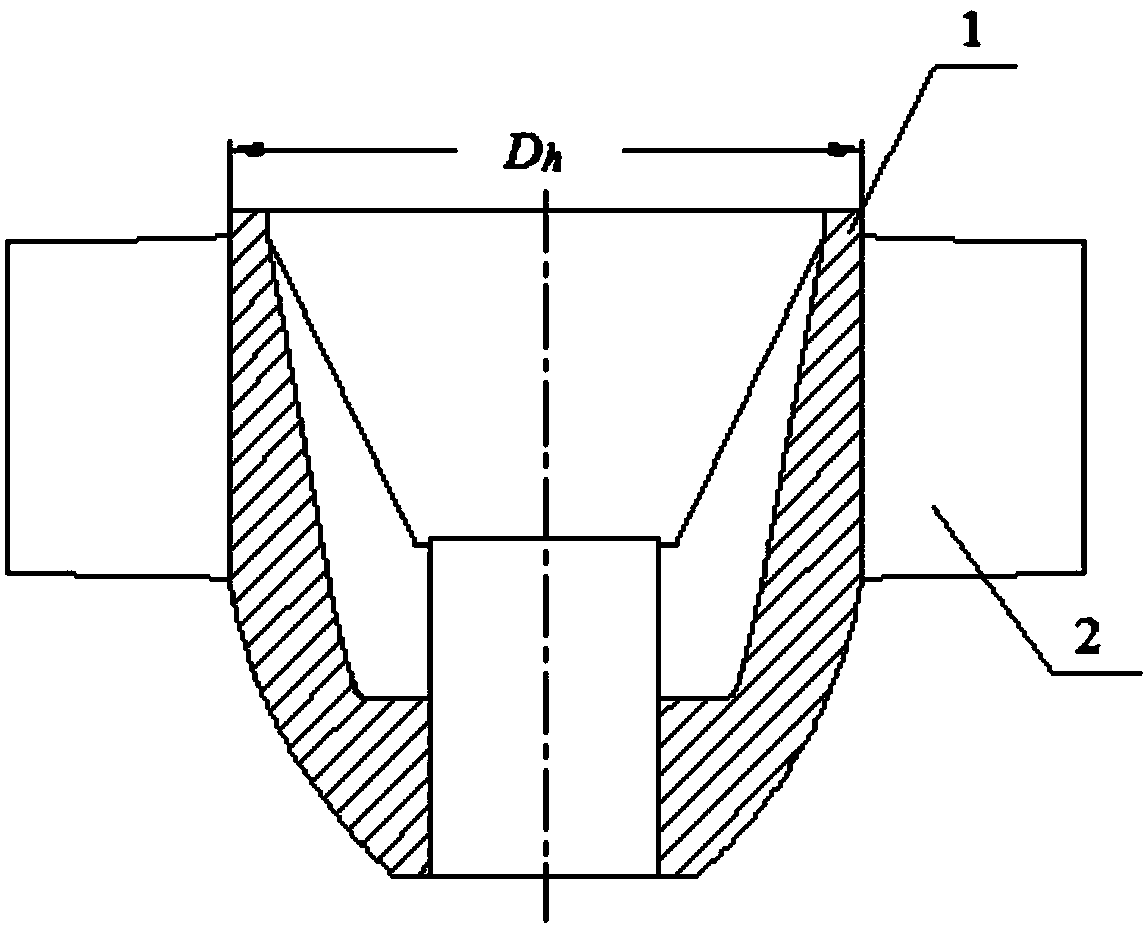

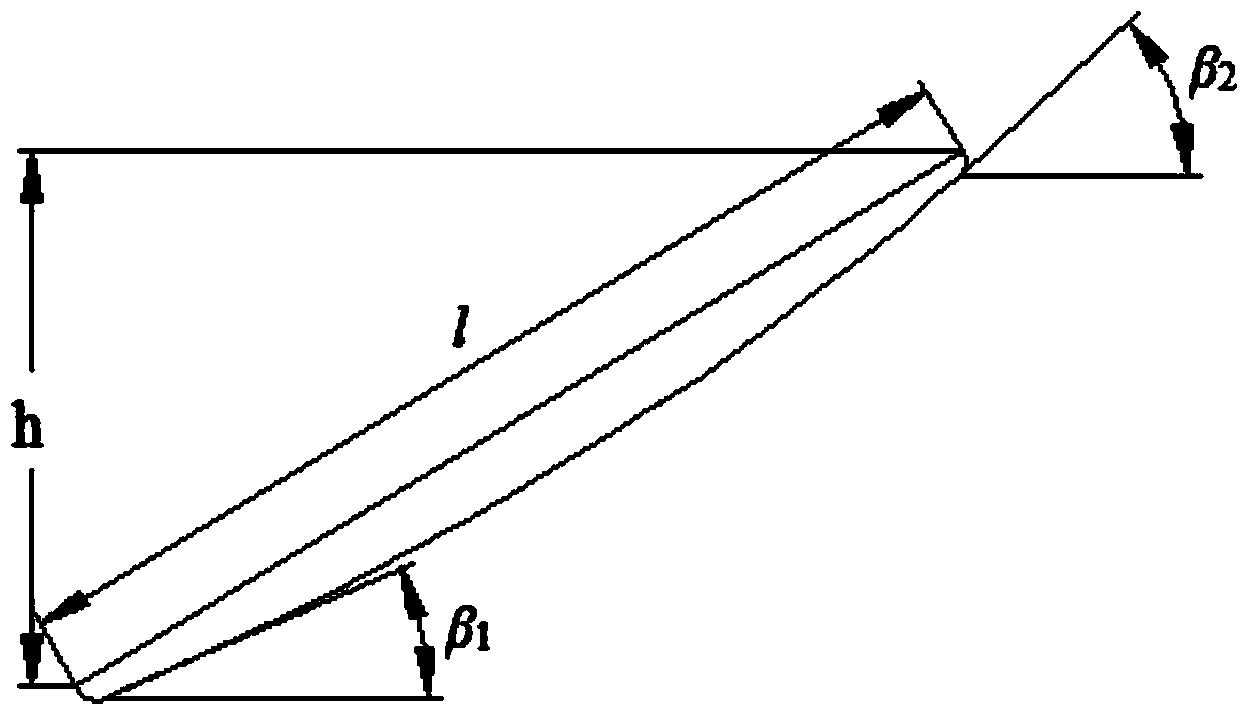

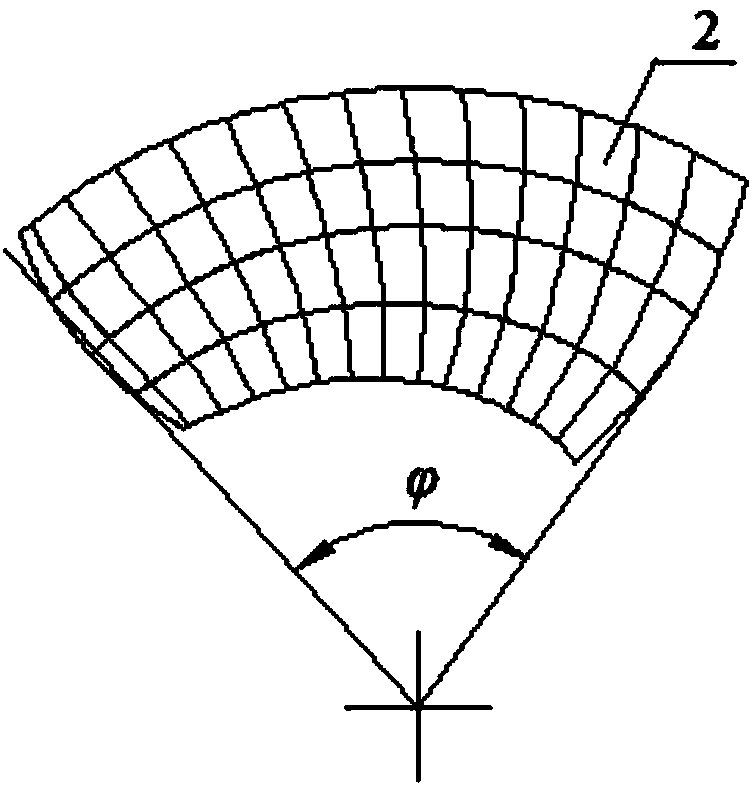

[0035] figure 1 , figure 2 , image 3 The multi-phase mixed-transport axial-flow pump impeller designed by the multi-working-condition design method of the present invention, in order to clearly illustrate the technical solution of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

[0036] In the multi-working-condition design method for the impeller of the multi-phase mixed-transport axial flow pump provided by the present invention, the number of multiple working-condition points is set to be m, and i is any one of the working conditions.

[0037] (1) According to the flow Q of the pump to the optimal working point BEP , the head H of the optimal efficiency working condition point BEP , the impeller speed n, the specific speed n of the optimal efficiency working point sBEP , the i-th operating point flow rate Q i , the lift H of the i-th working point i The geometric parameters of the impeller a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com