Construction method of arched steel lifting molds of tunnel secondary lining arch foot curved wall

A construction method and arc-shaped steel technology, applied in tunnel lining, tunnel, shaft lining, etc., can solve the problem of trolleys being difficult to reduce to a safe and flexible walking height and width, slow construction progress of the second lining, and increased safety distance, etc. problems, to achieve the effect of saving manpower, reducing construction procedures and improving construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

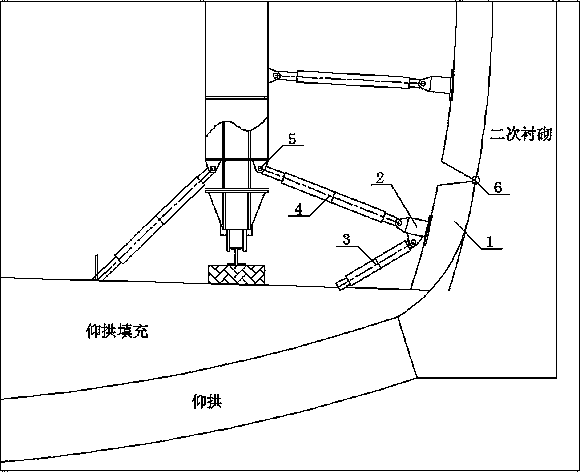

[0027] Example The construction method of arc-shaped steel hanging formwork for the curved wall of the arch foot of the second lining of the tunnel includes the following steps:

[0028] (1) The 12mm thick steel plate is machined into two shaped steel hanging molds 1 with arc lengths of 75cm and 44.4cm respectively, a width of 150cm and a connecting hinge 2 in the middle.

[0029] Wherein: connecting hinge 2 is all welded on the back side of two stereotyped steel hanging molds 1.

[0030] (2) Connect the connecting hinges 2 in the two shaped steel hanging molds 1 to the foot connecting hinges 5 on both sides of the trolley door frame through the screw rod 4 .

[0031] Among them: the screw rod 4 is 121.3cm and 119.3cm long (the screw rod can be extended or shortened by rotation, and the length here is the length of the screw rod when the panel is in the design curve), and it is connected with the connecting hinge 2 by pins.

[0032] (3) The connecting hinge 2 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com