Novel wharf structure quickly constructed on soft foundation and construction method thereof

A soft soil foundation and wharf technology, applied in the field of wharf engineering, can solve problems such as difficulty in ensuring long-term strength and stability, poor bending resistance and anti-overturning ability, complex interaction relationship, etc., to achieve light weight and enhanced integrity , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

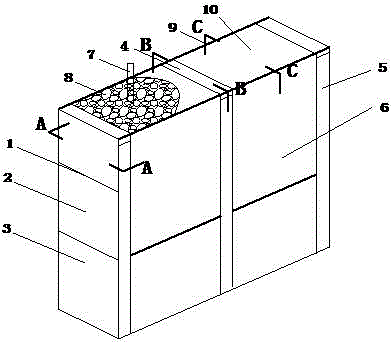

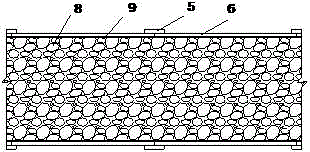

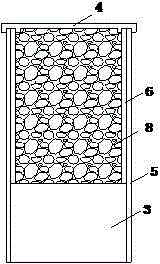

[0035] Such as Figure 1~5 As shown, the rapid construction of the new wharf structure on the soft soil foundation includes two rows of long piles 5 and two rows of short pile slabs 6 symmetrically arranged, and the two rows of short pile slabs 6 are arranged on the opposite inner sides of the two rows of long piles 5 respectively. A short sheet pile 6 is arranged between two adjacent long piles 5 in the row of long piles 5, and the joints of the adjacent short sheet piles 6 are covered by the long piles 5 arranged outside the short sheet piles 6; Geotextiles 9 are laid on the opposite inner sides of the two rows of short pile slabs 6, and an area for filling is formed between the geotextiles 9 on both sides, and the grouting pipes 7 are arranged vertically at equal intervals in a quincunx-shaped arrangement in this area. , the interval between adjacent grouting pipes 7 is 4~7m, and gravel complex 8 is filled in this area; among them, the two rows of symmetrically arranged lon...

Embodiment 2

[0037] A construction method for rapid construction of a new wharf structure on a soft soil foundation comprises the following steps:

[0038] 1) Clean up the site and set out the wires;

[0039] 2) Two rows of long piles 5 are laid along the direction of the wharf. Each long pile 5 passes through the soft soil layer 2 and penetrates into the bearing layer 3 to a depth greater than 4m. The distance between adjacent long piles in each row of long piles 5 2~5m;

[0040] 3) Short sheet piles 6 are inserted inside the two long piles 5 on each side. The length of the short sheet piles 6 penetrates the soft soil layer 2 to reach the top of the bearing layer 3, and the joints of adjacent short sheet piles 6 are set The long pile 5 covering on the outside of the short sheet pile 6;

[0041] 4) Two rows of symmetrical long piles 5 and short sheet piles 6 are fixed by beam 4;

[0042] 5) Lay geotextiles 9 inside the two rows of short sheet piles 6, and vertically arrange grouting pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com