Reducing slag collecting box for metallic magnesium smelting and high-pressure slag skimming charging system

A technology of charging system and collection box, applied in the field of reducing slag collection box, to achieve the effect of eliminating a large amount of escape and splash and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

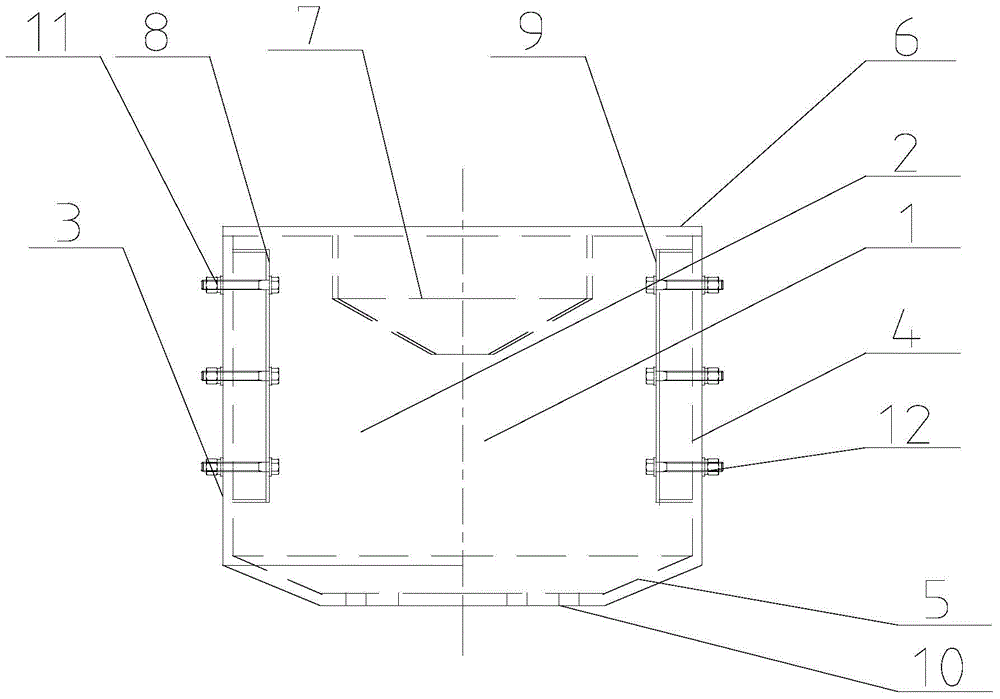

[0014] Example 1: A reduced slag collection box for a high-pressure slag removal charging system for metal magnesium smelting

[0015] How it works:

[0016] The reduced slag collection box consists of a left cover plate 1, a right cover plate 2, a front cover plate 3, a rear cover plate 4, a lower cover plate 5, and an upper cover plate 6. The blocking fireproof board Ⅰ8 and the blocking fireproof board Ⅱ9 are respectively connected with the front cover 3 and the rear cover 4 of the box through the connecting bolts Ⅰ11 and Ⅱ12 respectively, so as to block the high-temperature reducing slag in the box. The dust removal swirl plate 7 is welded on the upper cover plate 6 of the box body. The lower cover plate 5 of the casing is a conical body with an opening in the middle. The grid deflector 10 is welded on the lower cover plate 5 of the box body. After the high-speed running high-temperature reducing slag enters the reducing slag collection box, it will impact the dust-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com