Two-stage continuous lignite upgrading system

A lignite, tunnel-type technology, applied in the petroleum industry, solid fuel, fuel, etc., can solve the problems of reducing calorific value, pollution, and high temperature, and achieve the effect of low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

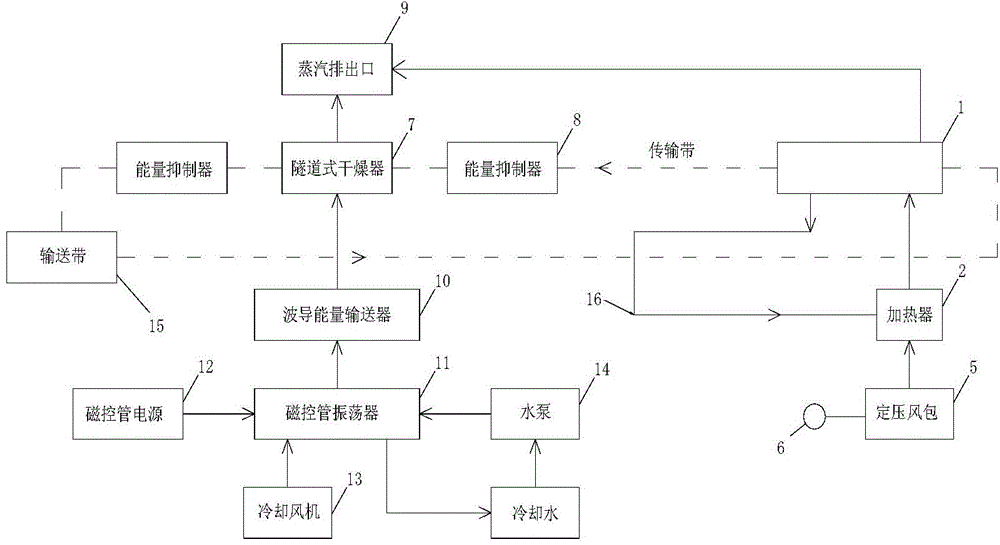

[0017] Two-stage continuous lignite upgrading system of the present invention, its preferred embodiment is:

[0018] It includes an air fluidized bed pre-drying system and a microwave enhanced upgrading system, and the lignite treated by the air fluidized bed predrying system is sent to the microwave enhanced upgrading system through a conveyor belt for microwave irradiation treatment;

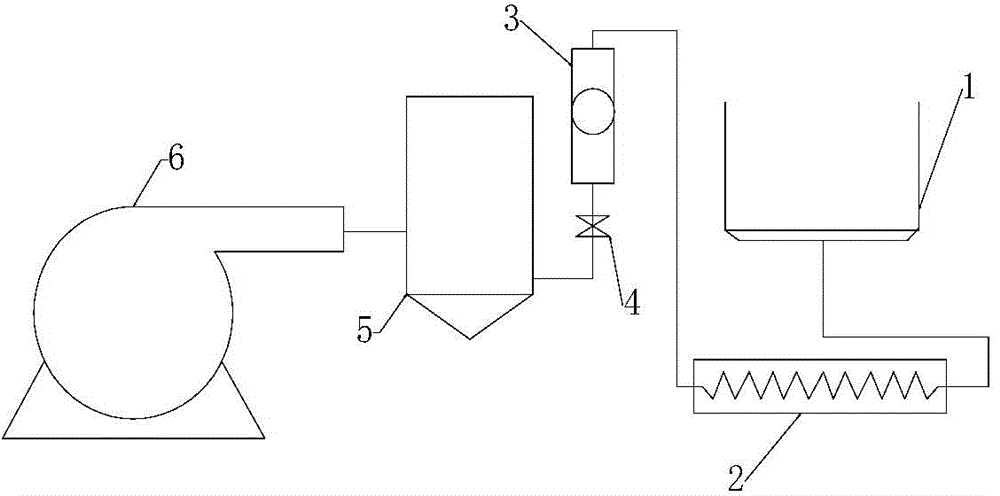

[0019] The air fluidized bed pre-drying system includes an air fluidized bed, a heater is provided on the circulating air duct of the air fluidized bed, and an air compressor, a constant pressure air bag, a valve, and a flow meter connected in sequence are also included. The outlet of the flow meter is connected with the circulating air duct of the air fluidized bed through the heater;

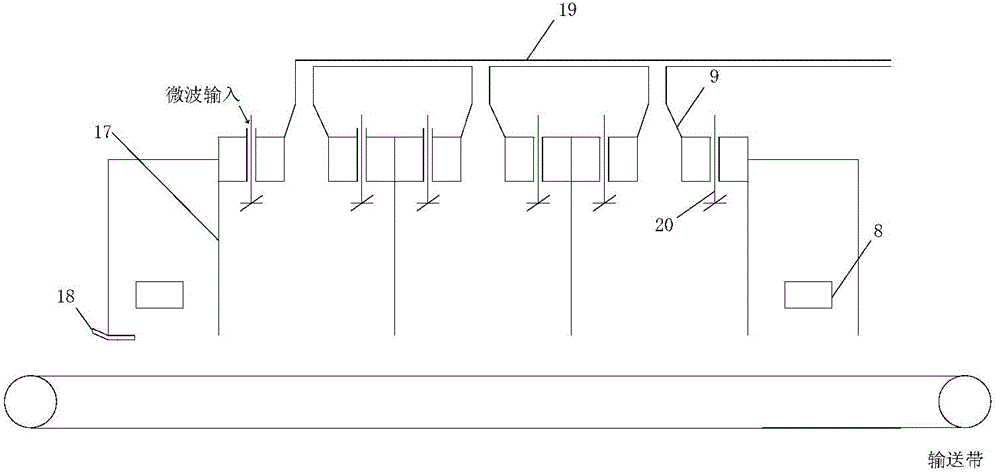

[0020] The microwave-enhanced upgrading system includes a tunnel-type microwave upgrader, and energy suppressors are arranged at the inlet and outlet of the box of the tunnel-type microwave upgrader.

[0021]...

specific Embodiment

[0052] See attached Figure 1-3 , the method includes an air fluidized bed pre-drying system, a microwave enhanced upgrading system and a conveyor belt 15 for carrying and transporting materials.

[0053] The specific implementation process of the above method is as follows:

[0054] The air compressor 6 blows fresh air into the constant-pressure wind bag 5, and the appropriate air flow is controlled through the valve 4, and its size is monitored by the flow meter 3. The air enters the fluidized bed 1 after being heated by the heater 2, so that the lignite in the fluidized bed 1 is fluidized, and the rapid and efficient pre-drying of the lignite is realized.

[0055] After the lignite is pre-dried in the first stage, it reaches the state of critical water content, and enters the tunnel-type upgrader 7 along with the conveyor belt for second-stage microwave enhanced upgrading. The structure of entering the microwave upgrader leveler 18 is as follows figure 1 Shown: A steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com