Low-temperature continuous synthesis method of rubber vulcanization accelerator NS

A rubber vulcanization and synthesis method technology, applied in the direction of organic chemistry, can solve the problems of high process risk, low yield of main product NS, and high difficulty in equipment manufacturing, so as to reduce the consumption of tert-butylamine, facilitate industrialization, and solve difficult wastewater treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

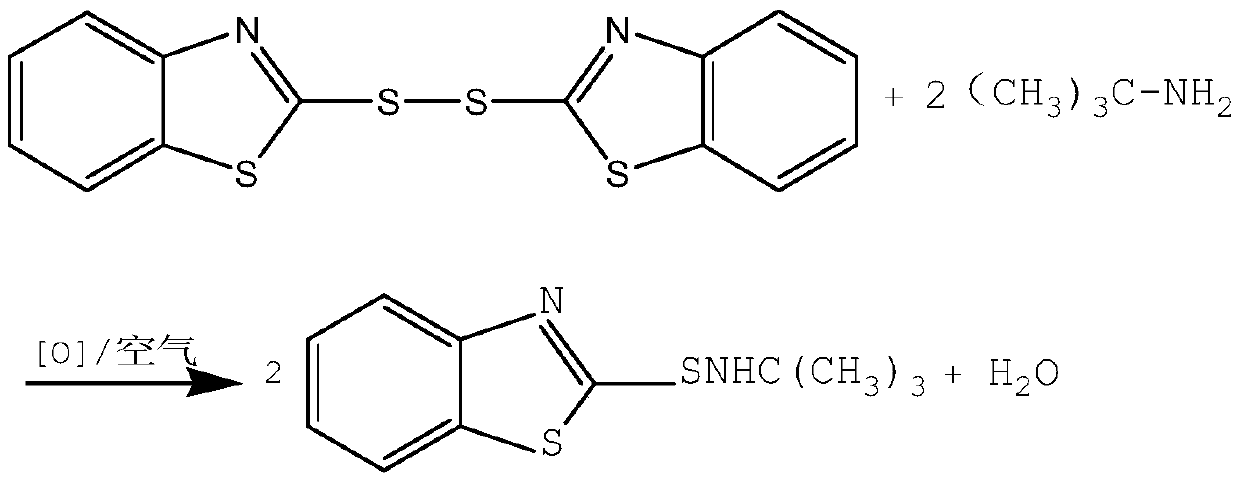

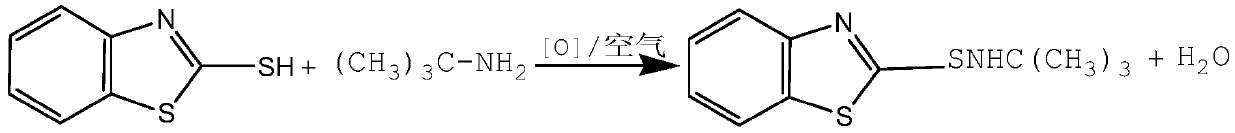

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Add 50g of rubber vulcanization accelerator M and 198g of rubber vulcanization accelerator DM into the reaction kettle, add 1000g of water into the kettle, start stirring at a speed of 300r / min, and weigh the 500g of good tert-butylamine is slowly added dropwise into the reaction kettle, and the dropping time is 30min;

[0029] Step 2: After the dropwise addition, control the switch valve of the condensing circulating water to control the temperature in the reactor at 5°C, and start slowly feeding in 123.1g of air at a rate of 3.18L / min to carry out the oxidation reaction, the reaction time For 30 minutes, take a sample to detect whether the product has reached the reaction end point, and test the purity by high performance liquid chromatography. The purity > 96% means that the reaction end point is reached; the purity detected by high performance liquid chromatography is 95.5%. Chromatography test purity is 97.5%;

[0030] Step 3: Filter, wash and dry the reac...

Embodiment 2

[0034] Step 1: Add 100g of rubber vulcanization accelerator and 99.4g of rubber vulcanization accelerator DM into the reaction kettle, add 1000g of water into the kettle, start stirring at a speed of 350r / min, after the materials in the kettle are mixed evenly, weigh A good 500g of tert-butylamine is slowly added dropwise into the reaction kettle, and the dropping time is 30min:;

[0035] Step 2: After the dropwise addition, control the switch valve of the condensing circulating water to control the temperature in the reactor at 10°C, and start to slowly introduce 98.84g of air at a rate of 2.19L / min to carry out the oxidation reaction. The reaction time It was 35min, and the purity of the sample was 98.5% by high performance liquid chromatography;

[0036] Step 3: Filter, wash and dry the reactant obtained in step 2 to obtain the NS product and mother liquor of the accelerator of the present invention. The obtained NS product has an average purity of 99.2%, and an average yi...

Embodiment 3

[0040] Step 1: Put 100g of rubber vulcanization accelerator M and 66.27g of rubber vulcanization accelerator DM into the reaction kettle, add Example 2 to the kettle to obtain 1000g of mother liquor, start stirring at a speed of 200r / min, and wait until the materials in the kettle are mixed evenly , slowly drop 500g of tert-butylamine weighed into the reaction kettle, and the dropping time is 27min;

[0041] Step 2: After the dropwise addition, control the switch valve of the condensing circulating water to control the temperature in the reactor at 8°C, and start slowly introducing 68.68g of air at a rate of 1.83L / min to carry out the oxidation reaction. For 40min, sampling with high performance liquid chromatography test purity is 98.3%;

[0042] Step 3: Filter, wash and dry the reactant obtained in step 2 to obtain the NS product and mother liquor of the accelerator of the present invention. The average purity of the obtained NS product was 99.1%, and the average yield was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com