A fully mixed large silo

A hybrid and silo technology, which is applied in the field of full-mix large silos, can solve problems such as poor feeding and large fluctuations in raw material composition in different batches, and achieve uniformity improvement, convenient daily inspection and maintenance, and applicability Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

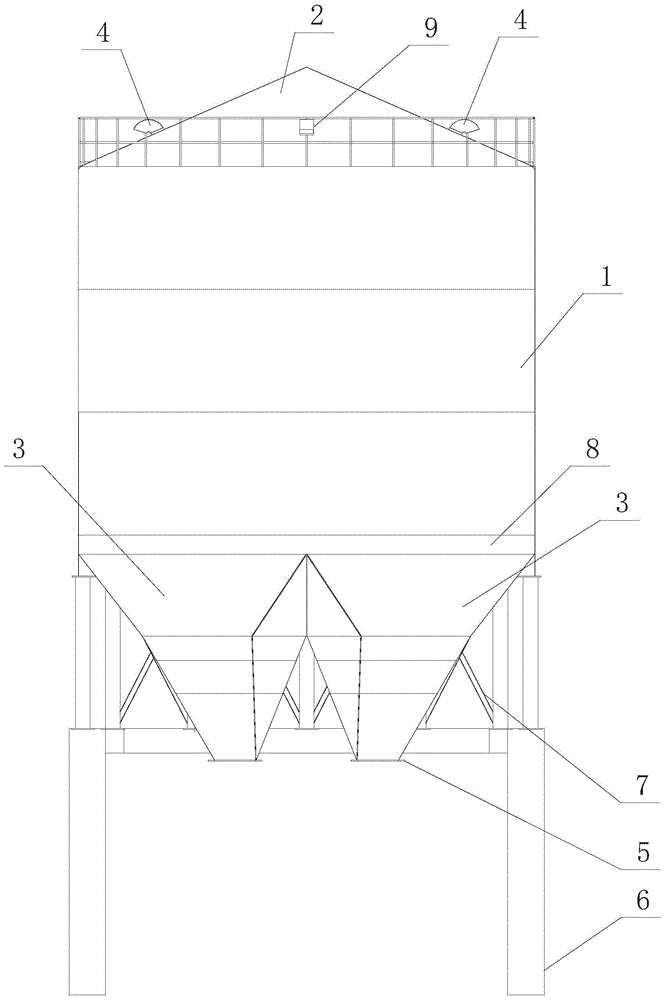

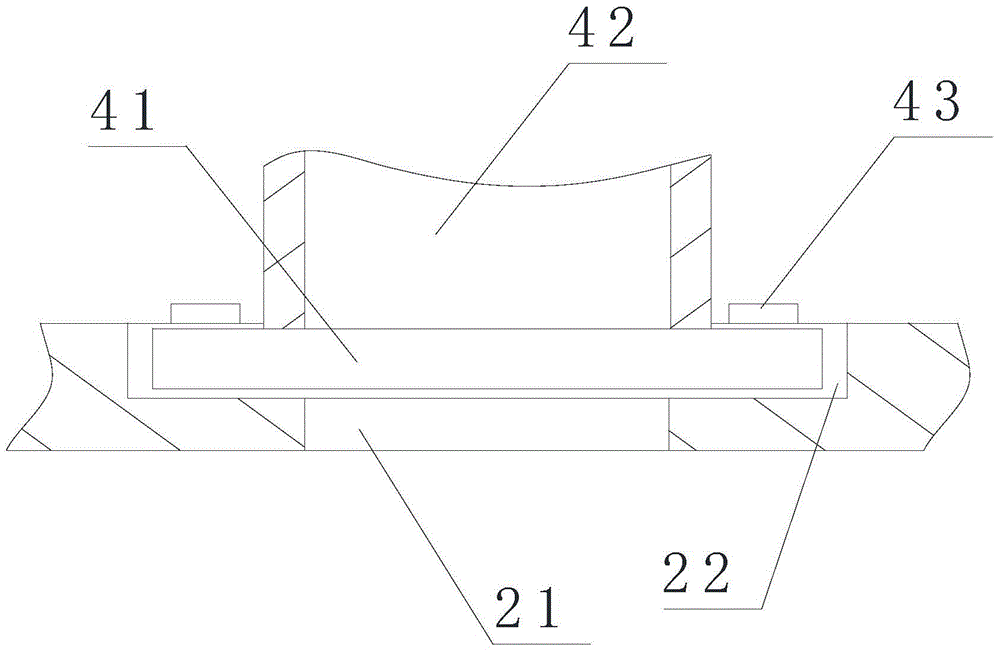

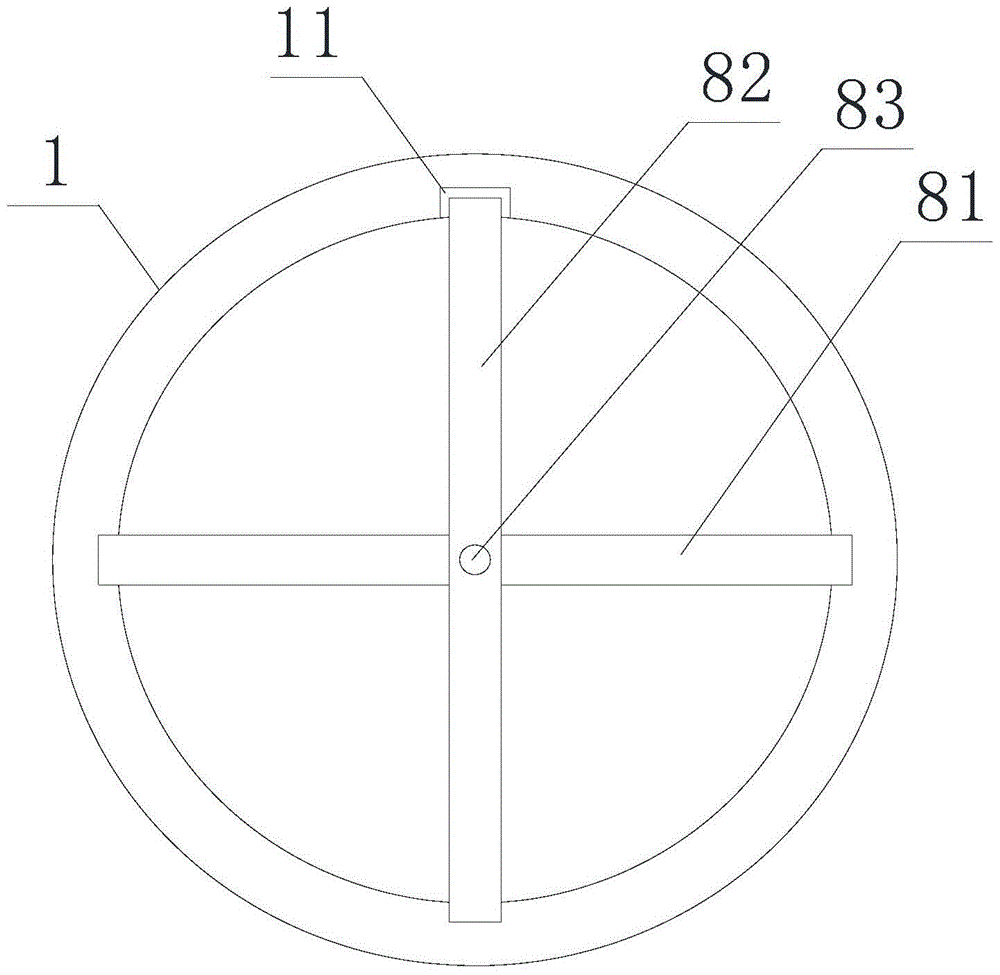

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a full-mixing large silo includes a cylinder 1, a detachable top cover 2 arranged at the top of the cylinder 1 and at least two detachable discharge pipes 3 arranged at the bottom of the cylinder 1. The diameter of the cylinder is 10m, and the capacity of the cylinder is 1000 cubic meters. The top cover 2 is set in a conical shape, and the top cover 2 is provided with several ventilation pipes for air pressure balance in the cylinder 1. 4. Each of the discharge pipes 3 is arranged in an inverted cone shape, the feed port of each of the discharge pipes 3 is eccentrically arranged with the discharge port of the discharge pipe 3, and each of the discharge pipes 3 The bottom ends are all provided with a flow regulating valve 5 for controlling the output of the discharge pipeline 3. The ventilation pipeline 4 is evenly arranged on the top cover 2, and the ventilation pipeline 4 includes a detachable connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com