Print head assembly, 3D printer and printing method

A 3D printer and print head technology, applied in the field of print head components, can solve problems such as inability to print, fast cooling speed, and large shrinkage, and achieve the effects of fast cooling speed, improved quality, and good molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

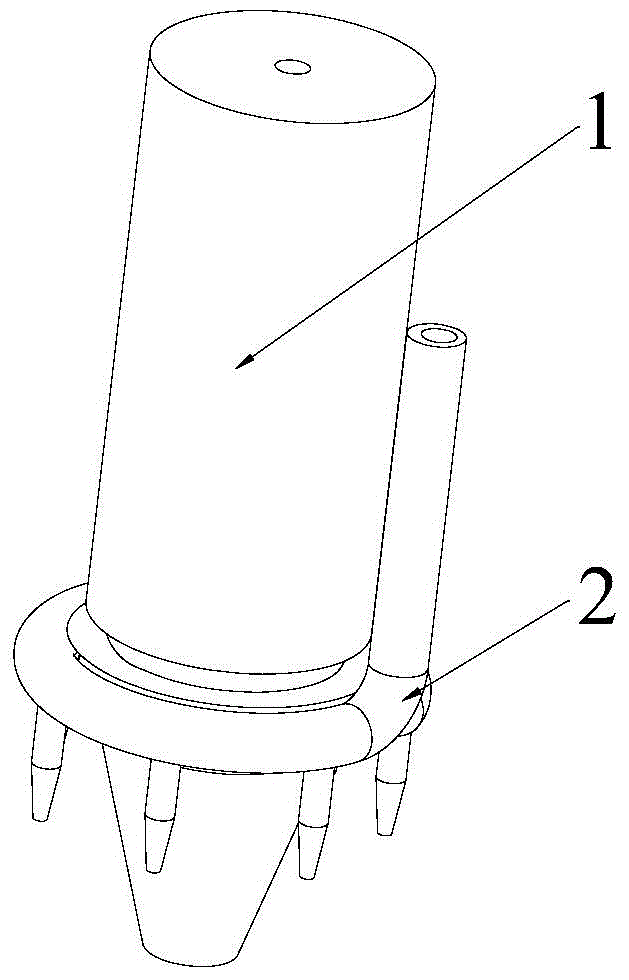

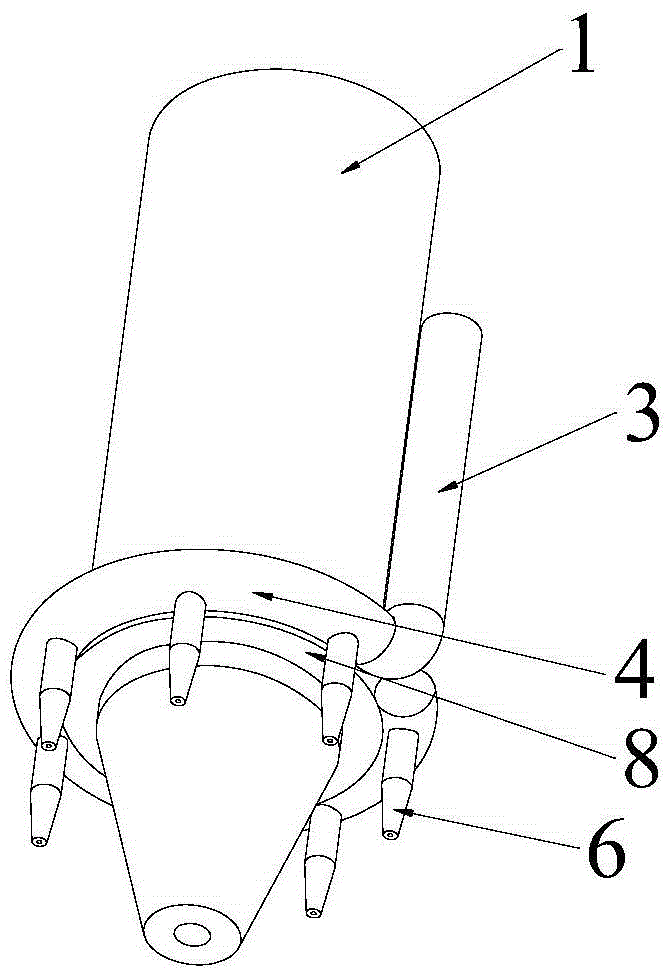

[0037] refer to figure 1 , this embodiment provides a print head assembly, which includes a print head body 1 and a heating device 2, the heating device 2 is arranged on the thermal head of the print head body 1, and is used to print and form the previous pass The substrate is heated.

[0038] The print head assembly of this embodiment, through the heating device 2 fixed on the thermal head of the print head body 1, heats the uppermost layer of the printed model under the print head body, that is, the substrate printed and formed in the previous pass. , and the substrate is heated to a slightly melted state on the surface, so that the subsequently printed material is better fused with the substrate, thereby effectively solving the problem of plastic materials (and other similar materials) with relatively large shrinkage during the 3D printing process The problem of 3D printing edge warping can also solve the problem of printing raw materials with fast cooling speed, and can s...

Embodiment 2

[0045] This embodiment provides a 3D printer, which includes the print head assembly described in Embodiment 1.

Embodiment 3

[0047] This embodiment provides a kind of 3D printing method, it adopts the 3D printer described in embodiment 2, comprises the following steps:

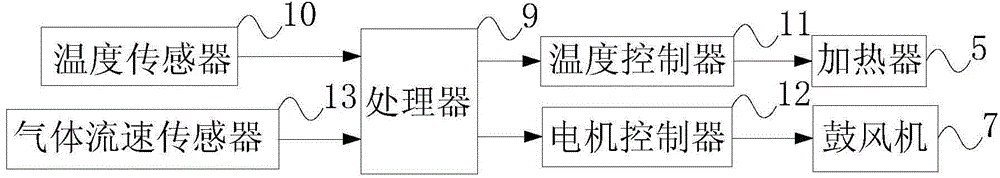

[0048] S10, start the 3D printer, and start the air volume control system;

[0049] S20. Adjust the air volume and air temperature according to the difference of the material to be formed and the difference of the printing speed;

[0050] S30, start 3D printing until the formed material is formed into a product.

[0051] In this embodiment, preferably, the 3D printing method further includes a step S25 between the steps S20 and S30:

[0052] S25. Place a bottom plate. The material of the bottom plate is the same as the material to be formed. At this time, 3D printing can be performed on the bottom plate. Since the printed layer can be well integrated with the bottom plate, it is not easy to produce Warping problem.

[0053] In this embodiment, the step S20 is specifically:

[0054] S201. Set 3D printing parameters, and generate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com