Portal robot welding machine

A robotic welding and door-type technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems that the special welding machine cannot meet the welding requirements, cannot meet the production needs, and has low production efficiency. Maintenance and cleaning, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

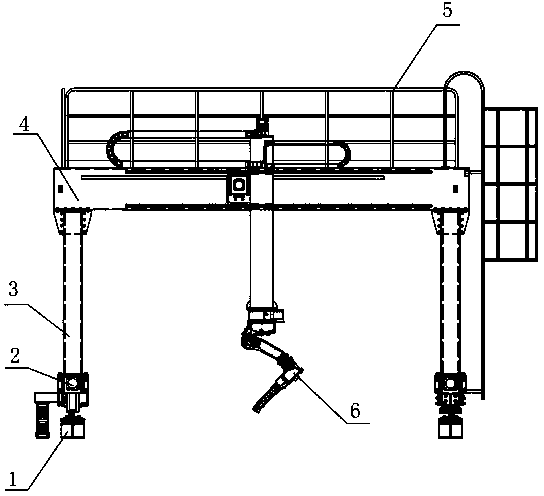

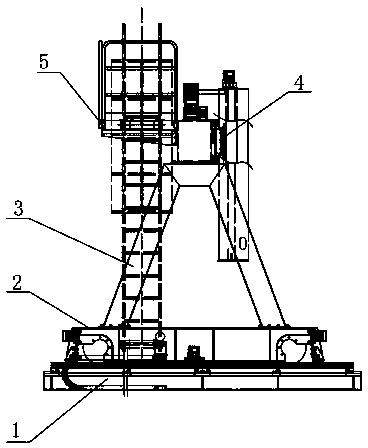

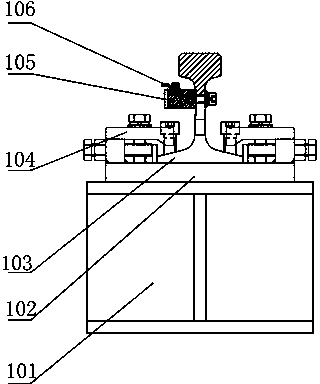

[0031] like figure 1 , figure 2 As shown, the gantry robot welding machine of this embodiment includes guide rail assemblies 1 arranged at intervals on the ground, a drive mechanism 2 is installed on the upper end of the guide rail assembly 1, and an inverted "V"-shaped column 3 is fixed on the upper end of the drive mechanism 2. Above the column 3 The welding arm cross moving mechanism 4 is installed, and the loading platform 5 is fixed at one end of the welding arm cross moving mechanism 4. A robot system 6 is installed on the bottom of the welding arm cross moving mechanism 4. The robot system 6 can carry out numerical control programming according to the shape and processing requirements of the workpiece. After inputting the instructions of NC programming, automatic welding is carried out on the workpiece to be processed, which has h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com