Structure for cleaning cavitation device by utilizing hyperventilation cavitating jet

A cavitator and jet technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of high energy consumption, environmental pollution, and high scrapping rate of oil pipes, and achieve reduced pump pressure, The effect of reducing energy consumption and increasing cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

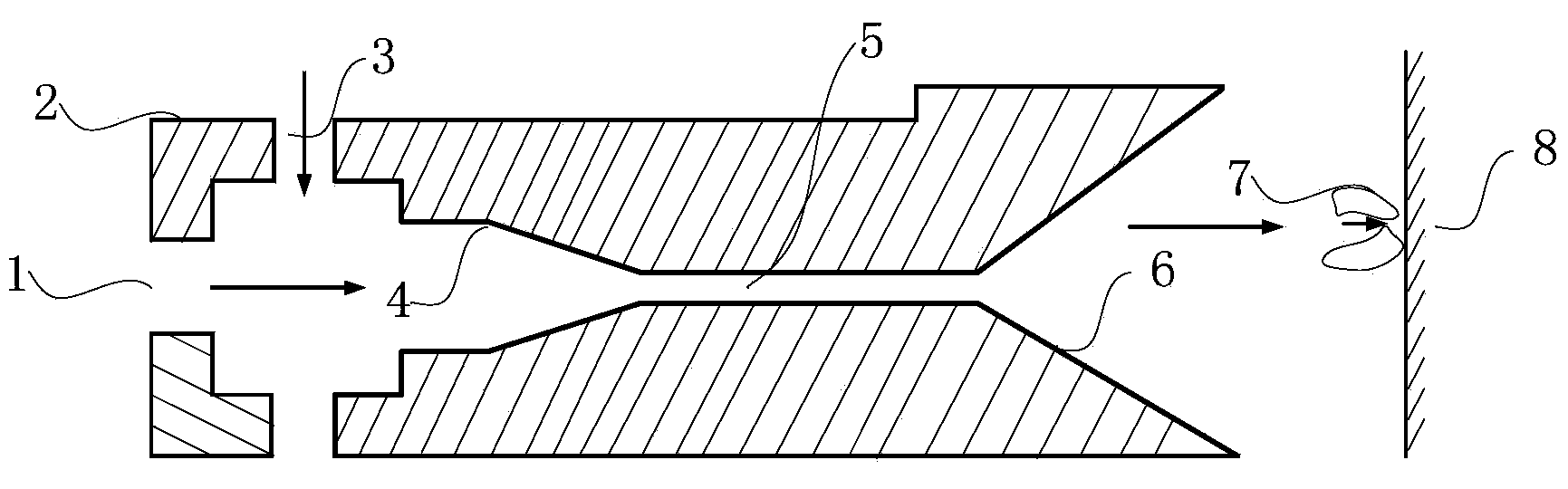

[0020] combine figure 1 , the present invention includes a cavitator nozzle inlet 1, a cavitator wall surface 2, a ventilation inlet 3, an internal constriction section 4 of the cavitator, an advection section 5 inside the cavitator, a diffusing section 6 inside the cavitator, and collapse bubbles 7, Objects to be cleaned 8. The structure mainly adds vent holes at the front end of the cavitation jet cavitator, and adds cavitation cores in the water jet. Realize the gas participation in the upstream of the nozzle, and the structure of the cavitation nozzle after adding the gas system is shown in figure 1 . Its working principle is to add an interface connected to the atmosphere upstream of the nozzle. When the water flow passes through the suction cavity, it will increase the gas core content in the water by means of the boundary layer. In this way, the cavitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com