Power plant flue gas desulfurization absorption tower in-line chimney

A desulfurization absorption tower and chimney technology, applied in the field of flue gas desulfurization in power plants, can solve the problems that the blackness of the flue gas cannot truly reflect the pollution situation, the flue gas carries condensate, and the vertical diffusion speed is low, so as to increase the lifting height and spread Ability, prevention of flue gas backflow phenomenon, and the effect of preventing secondary entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

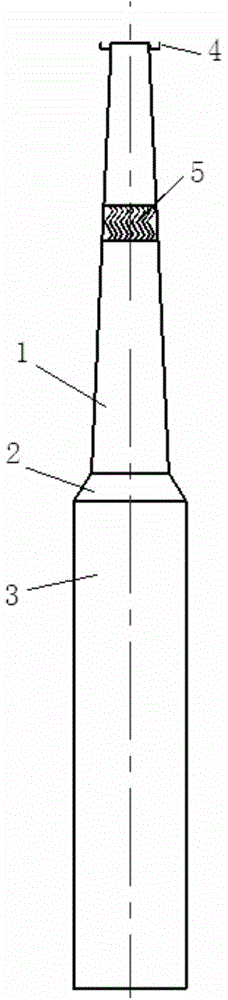

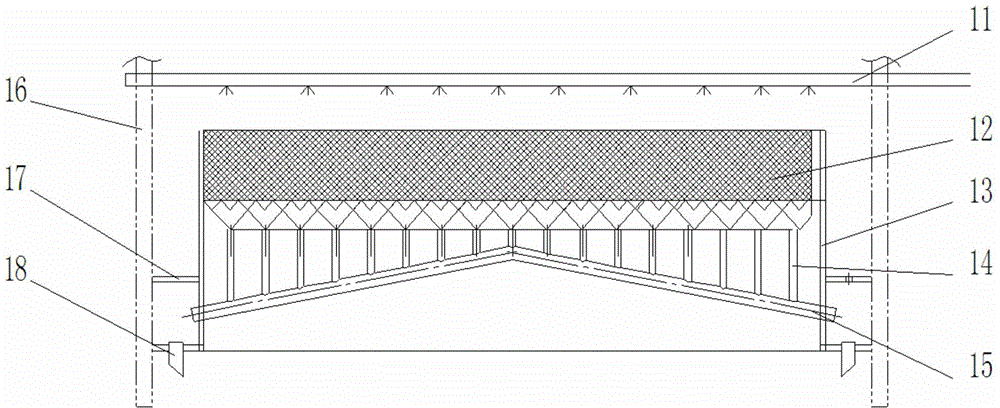

[0021] Such as Figure 2 to Figure 6 As shown, a power plant flue gas desulfurization absorption tower straight exhaust chimney, including a chimney 1, the chimney 1 adopts a conical cylinder structure, and the lower part of the conical cylinder is transitionally connected with the absorption tower 3 through an intermediate conical cylinder 2 , The upper part of the inner cavity of the conical cylinder 1 is provided with a defogging device 5 , and the outside of the top opening of the conical cylinder is provided with a condensate return device 4 .

[0022] Figure 5 , Figure 6 The condensate return device of the present invention includes an annular flap 21, a reinforcing rib 22, a return pipe 23, and a tower wall 24, which can collect and return the condensed liquid in a certain ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com