Ice-cold breathable type gel double-layer mattress and production process

A production process and breathable technology, applied in the field of mattresses, can solve the problems of hot back, easy sweating, physical discomfort affecting sleep, etc., and achieve the effects of good cooling effect, good air permeability and good comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

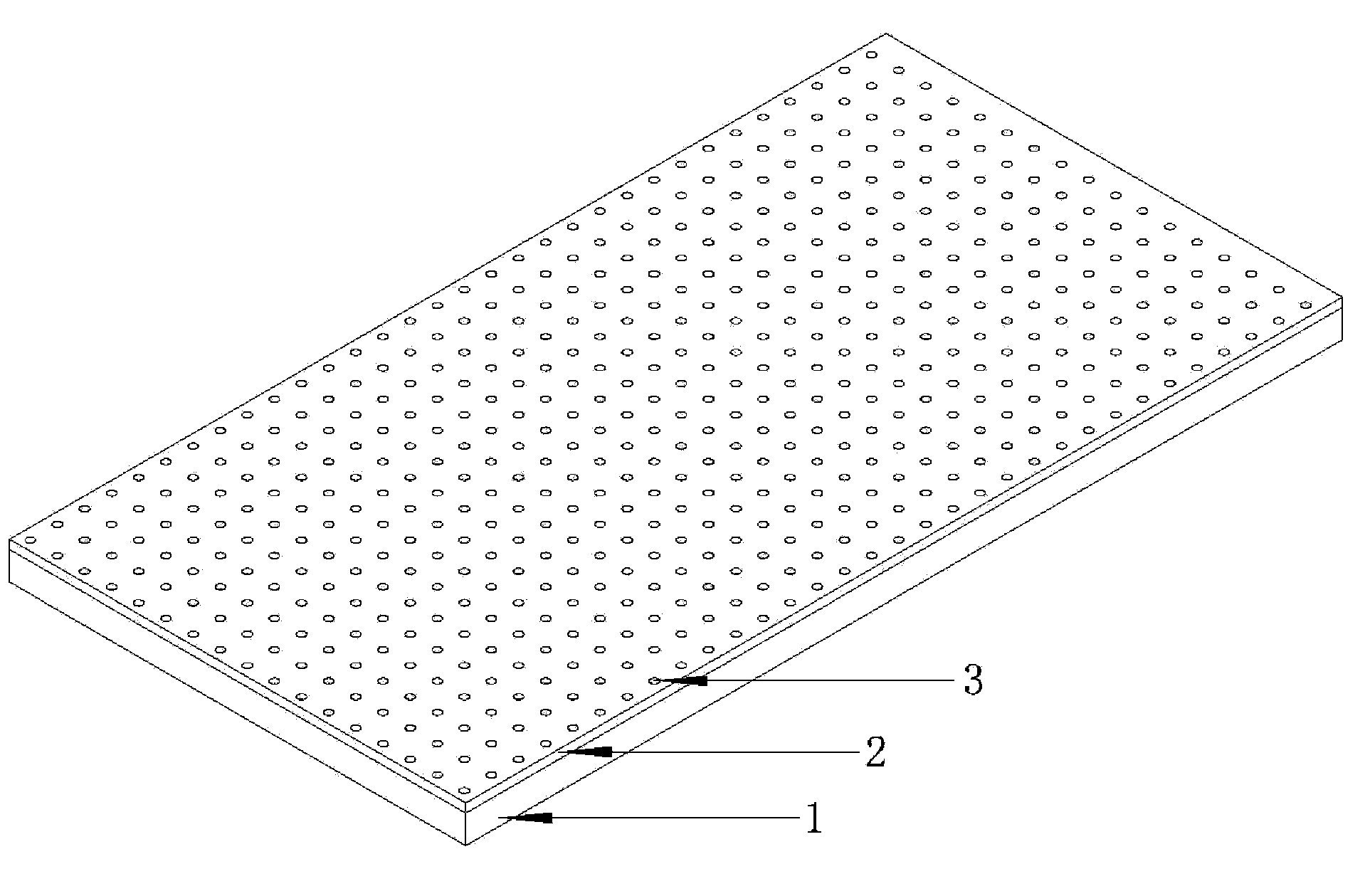

Image

Examples

Embodiment 1

[0023] Formula: polyether polyol 70%, isocyanate compound 29.5%, polyurethane gel catalyst 0.5%.

[0024] 1) First pump the above three raw materials into the raw material cylinder of the injection molding machine, and control the temperature of the raw materials at 10°C;

[0025] 2) Determine the mixing ratio of raw materials by adjusting the pumping flow of each raw material of the injection molding machine. After determining the formula, start the injection molding machine injection mode to inject the material into the two rollers of the roller machine, and adjust the thickness of the glue on the roller;

[0026] 3) Put the polyurethane sponge that has been punched to form evenly distributed air holes on the plastic plate, pass the conveyor belt through the roller machine and contact the roller for the first time glue, after glue, put it on the iron shelf to cure for 2 hours ;

[0027] 4) After the first curing is complete, carry out the second gluing, and put it on the ir...

Embodiment 2

[0029] Formula: polyether polyol 85%, isocyanate compound 14.99%, polyurethane gel catalyst 0.01%.

[0030] 1) First pump the above three raw materials into the raw material cylinder of the injection molding machine, and control the temperature of the raw materials at 40°C;

[0031] 2) Determine the mixing ratio of raw materials by adjusting the pumping flow of each raw material of the injection molding machine. After determining the formula, start the injection molding machine injection mode to inject the material into the two rollers of the roller machine, and adjust the thickness of the glue on the roller;

[0032] 3) Put the polyurethane sponge that has been punched to form evenly distributed air holes on the plastic plate, pass the conveyor belt through the roller machine and contact the roller for the first time glue, after glue, put it on the iron shelf to cure for 1 hour ;

[0033] 4) After the first curing is complete, carry out the second gluing, and put it on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com