Manufacturing method of axle counting cable for urban rail transit

A technology for urban rail transit and a manufacturing method, which is applied in the field of axle-counting cables for urban rail transit, can solve problems such as inability to use high-speed rail transit, large attenuation, and poor shielding performance, and meet the requirements of the rail transit environment, small attenuation, and The effect of excellent shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

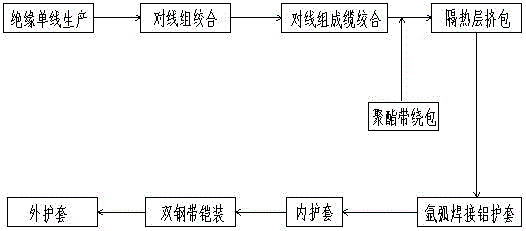

[0026] Refer to attached figure 1 , 2 , Axle counting cables for urban rail transit include insulated single wire 1, cable core 4, polyester tape 5, heat insulation layer 6, aluminum sheath 7, inner sheath 8, double steel tape armor layer 9 and outer sheath 10.

[0027] The insulated single wire has a conductor, and an insulating layer is extruded outside the conductor. Two insulated single wires of different colors are twisted to form a paired wire group, and there are at least 2 pairs of wire groups. A cable core 4 is formed by twisting at least two pairs of wire groups, a polyester tape 5 is wrapped around the cable core, and a heat insulation layer 6 is extruded outside the polyester tape 5 . Heat insulating layer 6 adopts polyethylene, or other equivalent performance polyolefin materials.

[0028] An aluminum strip is longitudinally wrapped outside the heat insulating layer 6 , and an aluminum sheath 7 is formed by argon arc welding, and an inner sheath 8 is extruded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com