A parameter optimization method for cut stem drying fluidized bed based on quality statistics

A fluidized bed and drying technology, applied in calculation, electrical digital data processing, special data processing applications, etc., can solve problems affecting the interests of consumers, abnormal fluctuations of physical and chemical indicators such as suction resistance, combustibility, and affecting the quality of finished tobacco.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

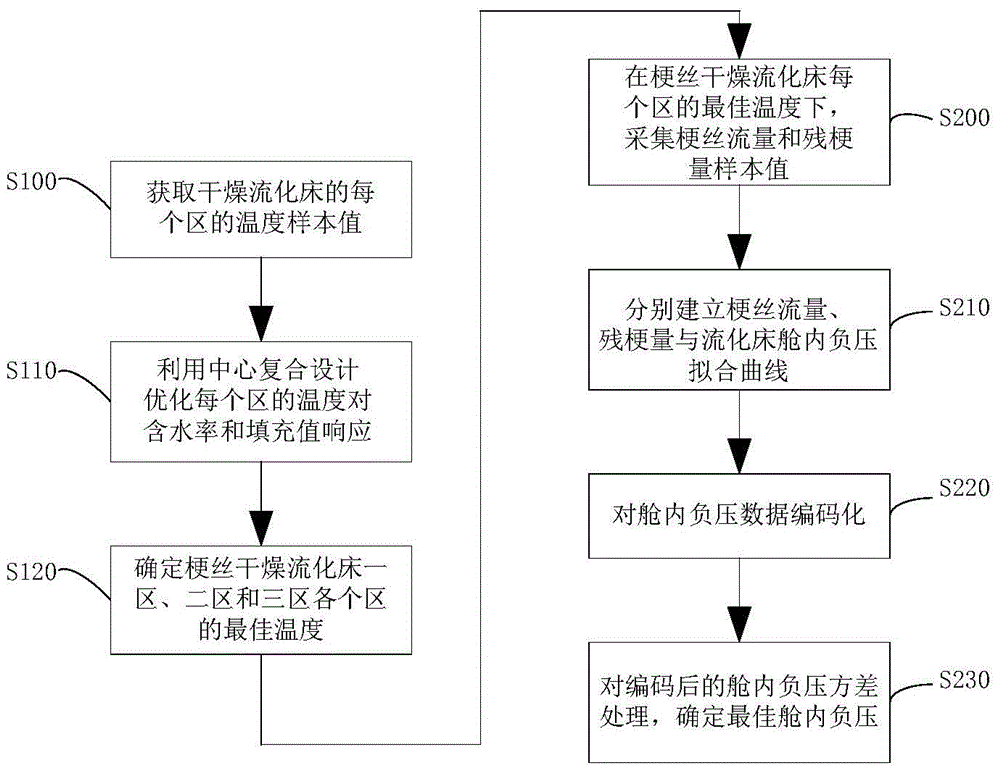

[0025] like figure 1 As shown, a parameter optimization method of stem cut drying fluidized bed based on quality statistics, including:

[0026] First carry out the temperature optimization of each zone of the cut stem drying fluidized bed:

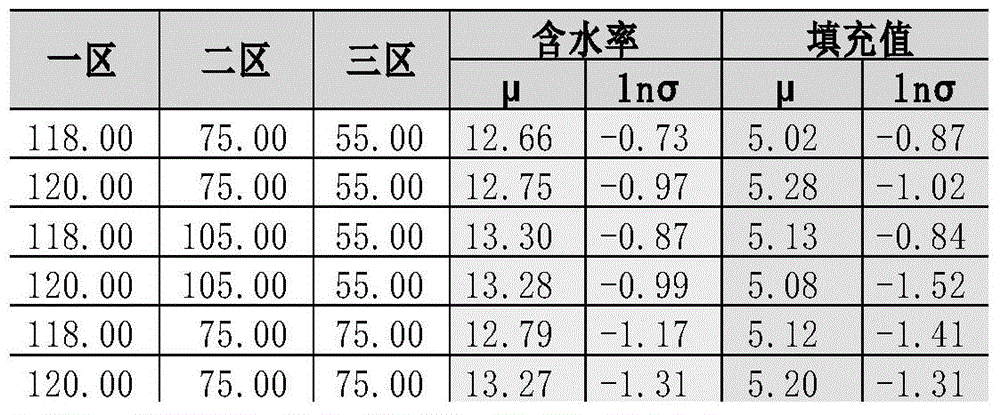

[0027] Step S100: Collect the temperatures in the first, second and third zones of the cut stem drying fluidized bed as influencing factors, and the responses are the moisture content Y 1 and fill value Y 2 , the temperature samples for each zone are X 1 、X 2 and x 3 ;

[0028] Step S110: using central composite design to optimize the temperature response of each zone of the fluidized bed to the moisture content and filling value;

[0029] Step S120: When the water content, filling value, and temperature value when the overall desirability is greater than 90%, the optimum temperatures of the first, second, and third sections of the cut stem drying fluidized bed are obtained.

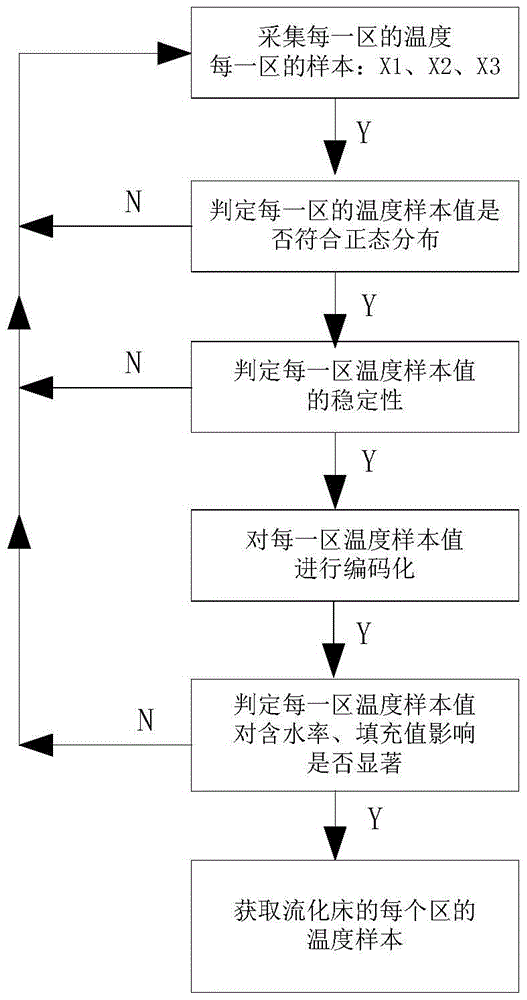

[0030] like figure 2 As shown, the temperature collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com