High definition image type measurement instrument

A measuring instrument, high-definition technology, applied in instruments, measuring devices, microscopes, etc., can solve problems such as low edge contrast, and achieve the effect of improving contrast, improving work efficiency, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

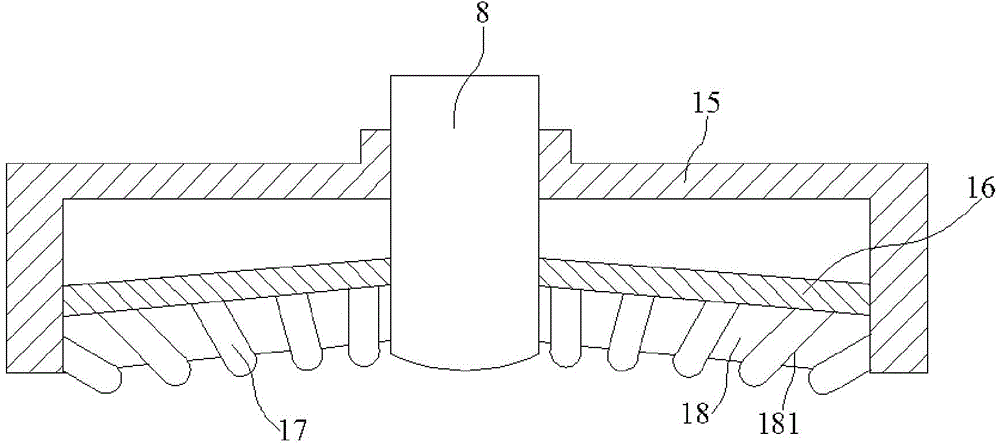

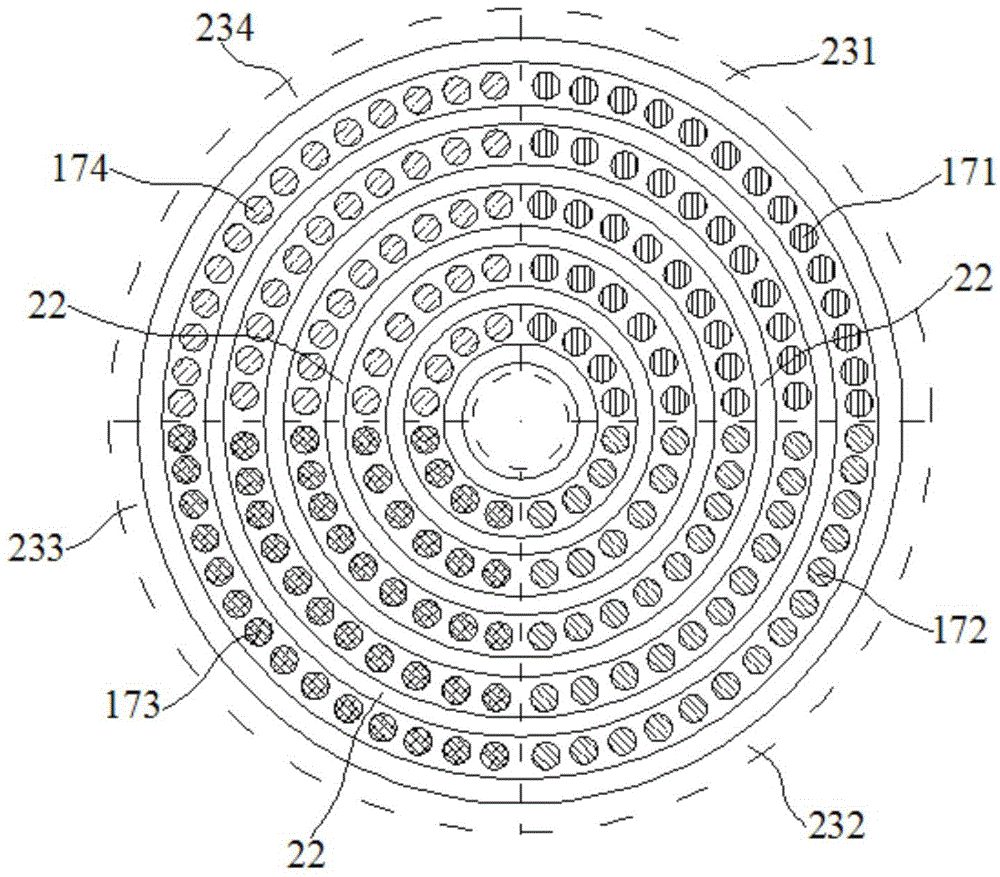

[0024] Embodiment: A kind of high-definition image type measuring instrument comprises a base 1, an LED lighting source 12, an image mirror sleeve 9 and a measuring table 2, and the image mirror sleeve 9 includes an encoder 24 and is composed of a second 1. The transmission system composed of the second and third gears 25, 26, and 27 meshing in sequence. A motor 20 and the encoder 24 are fixed on the Z-axis drive mechanism 10, and the first gear 25 is arranged on the output shaft of the motor 20. , the second gear 26 is arranged on the rotating shaft of the encoder 24, and the third gear 27 is arranged on the image mirror sleeve 9; The microscope magnifies, the image mirror sleeve turns right, and the focusing lens 8 times decreases. The rotation of the stepper motor 20 is controlled by the control signal sent by the control system. The rotation of the stepper motor 20 drives the sleeve to rotate through the transmission system, and the sleeve rotates to adjust the magnificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com