Power battery power test method and system

A power battery and power testing technology, which is applied in the direction of measuring electric power, electric vehicles, electrical devices, etc., can solve the problems of large amount of data calculation, inability to reflect the demand of power battery, complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

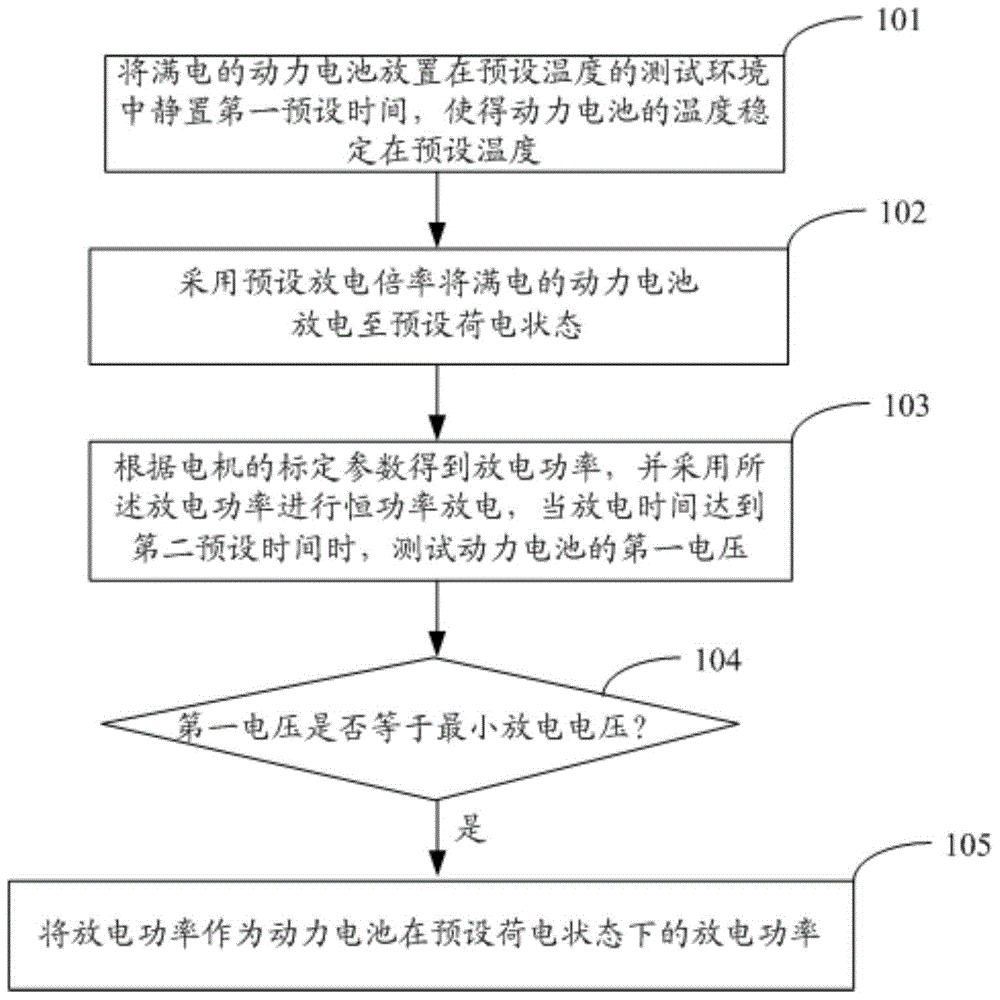

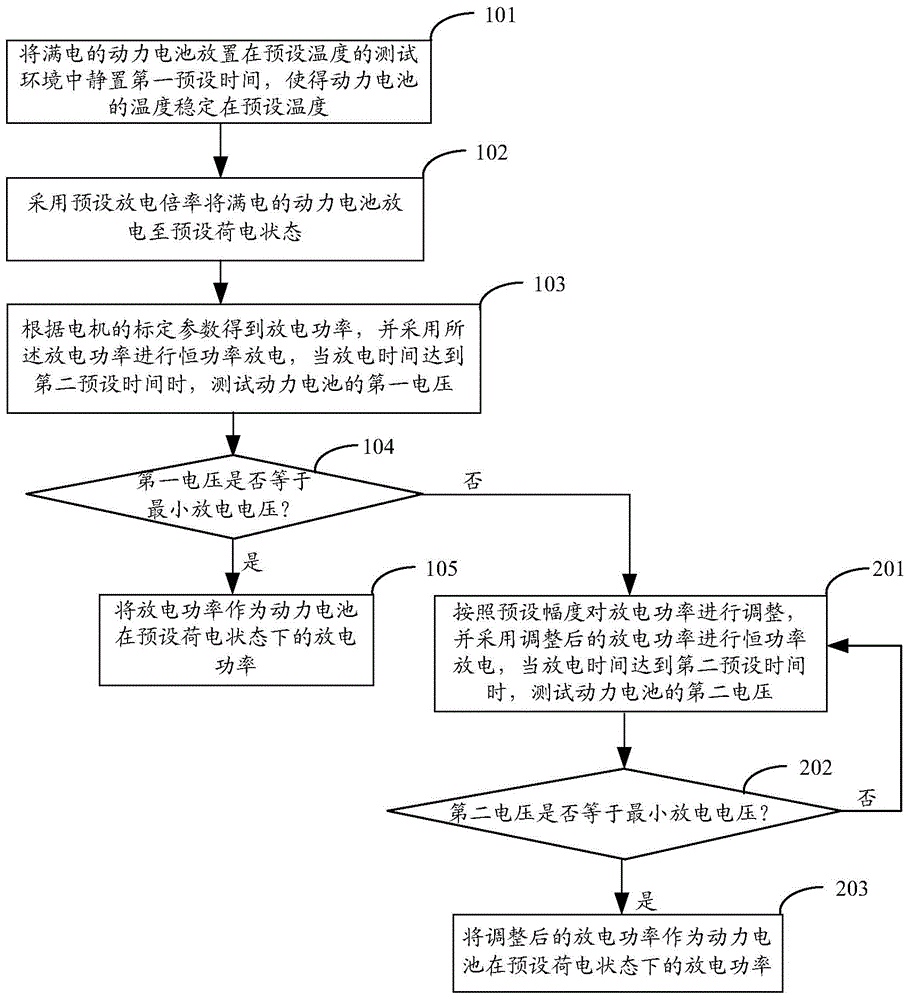

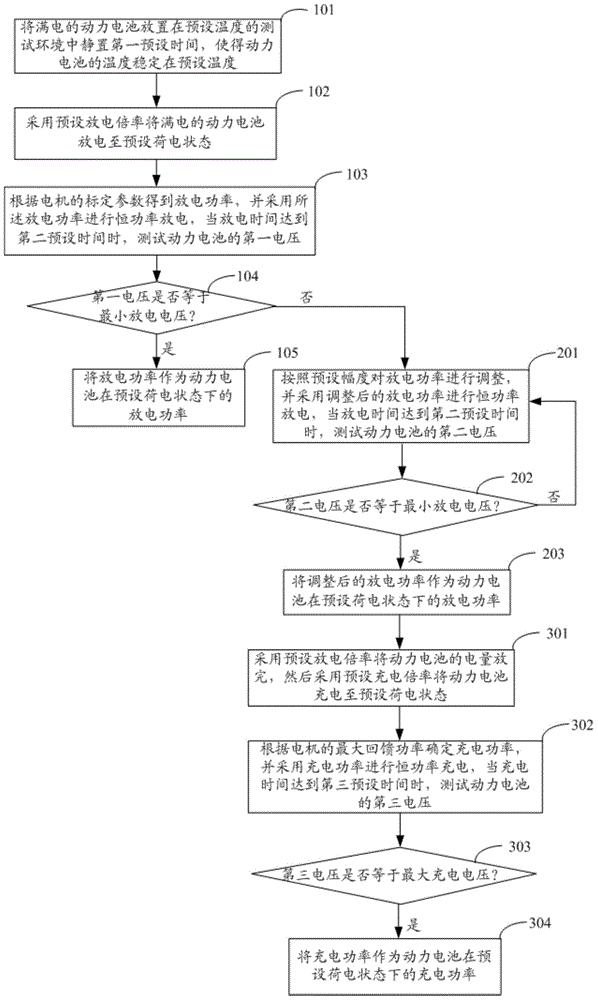

[0059] Such as figure 1 As shown, the power test method of the power battery includes:

[0060] Step 101: Place the fully charged power battery in a test environment at a preset temperature for a first preset time, so that the temperature of the power battery is stable at the preset temperature.

[0061] The above-mentioned test environment can be a high-low temperature box, specifically, the temperature in the high-low temperature box can be adjusted to the required test temperature according to actual needs, and the standing time (the first preset time) is set in advance, such as 1 hour, wherein , when the power battery is placed in the test environment for a first preset time, it can reach a steady state.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com