CFB radiation mixed boiler capable of reducing contamination of high-alkalinity coal

A highly alkaline, hybrid technology, applied in steam boilers, combustion types, fuels burned in a molten state, etc., can solve problems such as increased operating costs, insufficient boiler output, contamination, etc., to reduce contamination problems and reduce accumulation. The effect of gray level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

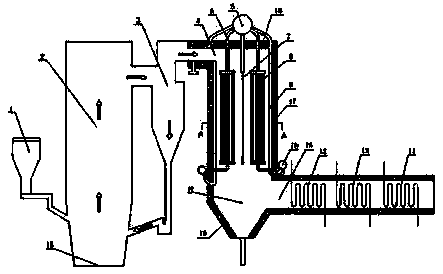

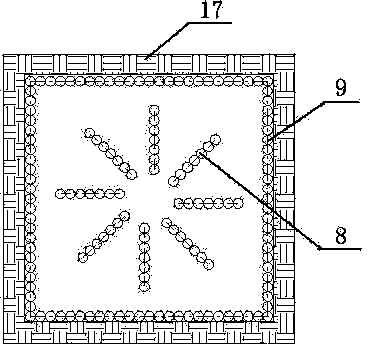

[0030] Such as Figure 1-2 As shown, a CFB radiant hybrid boiler for reducing contamination of highly alkaline coals includes a fluidized bed furnace 2, a cyclone separator 3, a horizontal flue 4, a radiant boiler 7 and a convection flue 16, and the fluidized bed furnace 2 is connected to the cyclone separator 3, and the cyclone separator 3 is connected to the radiant boiler 7 through the horizontal flue 4, and the bottom of the radiant boiler 7 is connected to the horizontal convection flue 16; the radiant boiler 7 is provided with a radiant water-cooled wall 9 and a radiant heat exchange The radiant water-cooled wall 9 is a rectangular structure formed by splicing a plurality of vertical risers, and the inside of the rectangular structure is a cavity; The heat shield 8 includes a plurality of vertical plane radiation sub-screens, each radiati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com