Artificial leather with water resistance, impact resistance and good heat insulation effects

An artificial leather and impact-resistant technology, applied in the field of artificial leather, can solve the problems of affecting the service life of artificial leather, poor thermal insulation effect of the base layer, short service life, etc., and achieve the goal of preventing heat from spreading outward, good thermal insulation effect, and super impact resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

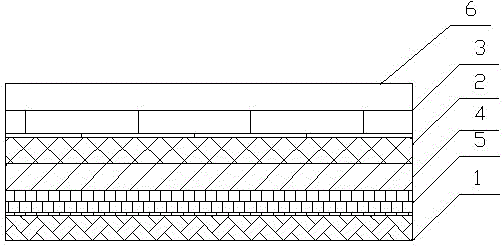

[0016] See figure 1 , The present invention relates to an artificial leather with good waterproof, impact-resistant and heat-preserving effects, including a base fabric layer 1, a first foam layer 2 and a dense surface layer 3. The first foam layer 2 is fixedly attached to the surface densely based on the state of use. On the inner surface of layer 3, the base fabric layer 1 is located on the side of the first foamed layer 2 facing away from the surface dense layer 3. A second foamed layer is also provided between the base fabric layer 1 and the first foamed layer 2. 4 and the impact-resistant layer 5, the second foamed layer 4 is located on the side of the first foamed layer 2, the impact-resistant layer 5 is located on the side of the base fabric layer 1, on the outer surface of the dense surface layer 3 A plastic film layer 6 is provided.

[0017] The base layer is made of a fabric, the fabric is interwoven by warp yarns and weft yarns, the warp yarns and weft yarns have a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com