Bending-resistant calendered leaf-yellow rubber edge strip rubber for liberation shoes, and preparation method and application thereof

A technology of rubber strip glue and Jiefang shoes, which is applied in the field of rubber material preparation, can solve problems such as unreasonable reinforcement system, large temperature fluctuation of rubber material performance, and unstable process performance, so as to improve scorch resistance and durability. Inflection performance, improved molding pass rate and service life, rubber quality and stable process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

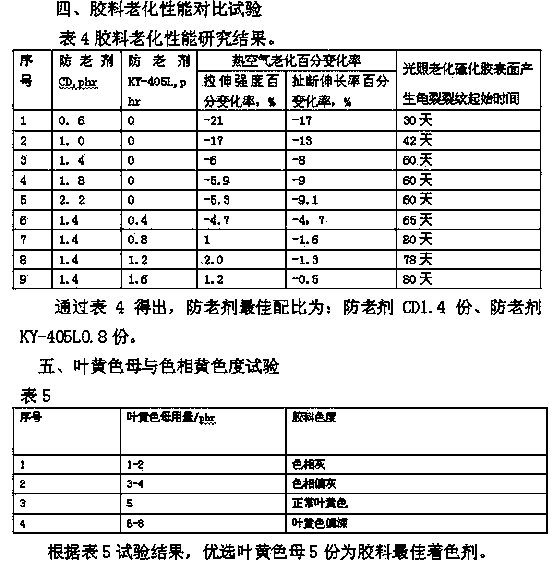

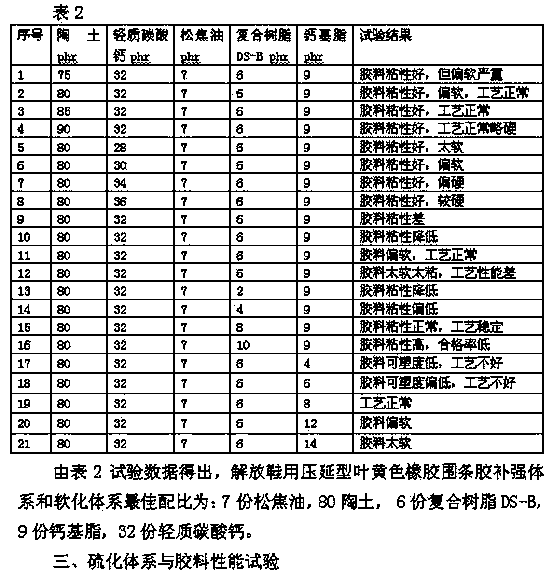

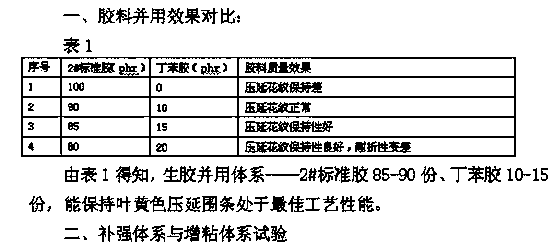

Examples

Embodiment 1

[0021] Embodiment 1 of the present invention: calendered leaf yellow rubber enclosure glue for tortuous and liberated shoes, calculated in parts by weight, including 80 parts of 2# standard glue, 20 parts of styrene-butadiene rubber, 20 parts of white carbon black, 2.2 parts of sulfur , 4 parts of vulcanization accelerator, 1.6 parts of stearic acid, 2 parts of active zinc oxide, 9 parts of pine tar, 65 parts of pottery clay, 2.2 parts of antioxidant, 6 parts of composite resin DS-B, 9 parts of 3# calcium base grease, 28 Parts of light calcium carbonate and 8 parts of leaf yellow masterbatch; wherein, every 108.7 parts of leaf yellow masterbatch is composed of 50 parts of rosin styrene-butadiene rubber, 4 parts of paraffin, 0.8 part of N330 carbon black, 0.9 part of phthalocyanine green G and 53 parts of medium Composed of chrome yellow; every 4 parts of vulcanization accelerator is composed of 2 parts of accelerator DM, 1.5 parts of accelerator M and 0.5 part of accelerator DS...

Embodiment 2

[0026] Embodiment 2 of the present invention: calendered leaf yellow rubber enclosure glue for tortuous and liberated shoes, calculated in parts by weight, including 75 parts of 2# standard glue, 25 parts of styrene-butadiene rubber, 15 parts of white carbon black, 2 parts of sulfur , 3.6 parts of vulcanization accelerator, 1.4 parts of stearic acid, 1.8 parts of active zinc oxide, 10 parts of pine tar, 60 parts of clay, 2.0 parts of anti-aging agent, 4 parts of composite resin DS-B, 10 parts of 3# calcium base grease, 34 parts Parts of light calcium carbonate and 9 parts of leaf yellow masterbatch; wherein, every 108.7 parts of leaf yellow masterbatch is composed of 50 parts of rosin styrene butadiene rubber, 4 parts of paraffin, 0.8 part of N330 carbon black, 0.9 part of phthalocyanine green G and 53 parts of medium Composed of chrome yellow; every 4 parts of vulcanization accelerator is composed of 2 parts of accelerator DM, 1.5 parts of accelerator M and 0.5 part of acceler...

Embodiment 3

[0028] Embodiment 3 of the present invention: calendered leaf yellow rubber wrapping glue for tortuous and liberated shoes, calculated in parts by weight, including 85 parts of 2# standard glue, 15 parts of styrene-butadiene rubber, 25 parts of white carbon black, and 2.4 parts of sulfur , 3.6 parts of vulcanization accelerator, 1.8 parts of stearic acid, 2.2 parts of active zinc oxide, 8 parts of pine tar, 70 parts of clay, 2.4 parts of anti-aging agent, 8 parts of composite resin DS-B, 8 parts of 3# calcium base grease, 26 parts 1 part of light calcium carbonate and 7 parts of leaf yellow masterbatch; wherein, every 108.7 parts of leaf yellow masterbatch is composed of 50 parts of rosin styrene-butadiene rubber, 4 parts of paraffin, 0.8 part of N330 carbon black, 0.9 part of phthalocyanine green G and 53 parts of medium Composed of chrome yellow; every 4 parts of vulcanization accelerator is composed of 2 parts of accelerator DM, 1.5 parts of accelerator M and 0.5 part of acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com