Novel heave compensation system and method for offshore crane

A heave compensation and crane technology, applied in the direction of crane, spring mechanism, hoisting device, etc., can solve the problems of low compensation accuracy, high power consumption, limitation of system compensation performance, etc., and achieve high compensation accuracy and wide application range. , the effect of strong portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is described in detail below in conjunction with accompanying drawing:

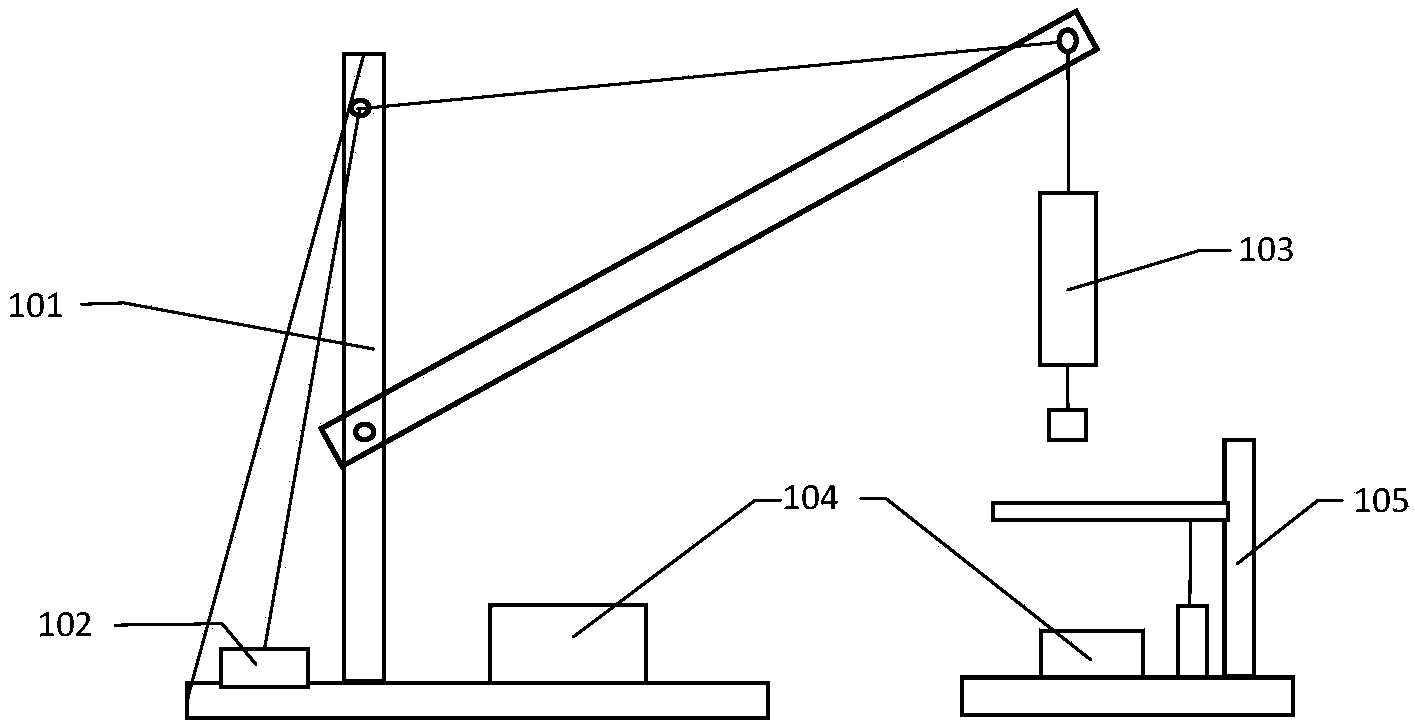

[0048] like figure 1 As shown, the present invention discloses a new offshore crane heave compensation system, including a lifting device 101, a winch 102, a heave compensation execution device 103, a controller 104, a ship heave simulation system 105, and a heave compensation execution device 103 is hoisted on the lifting device, and the ship heave motion simulation system is installed under the heave compensation actuator, and the lifting device 101, the heave compensation actuator 103, and the ship heave simulation system 105 are controlled by the controller to realize the heave The mutual cooperation between the compensation execution device and the ship heave simulation system 105 .

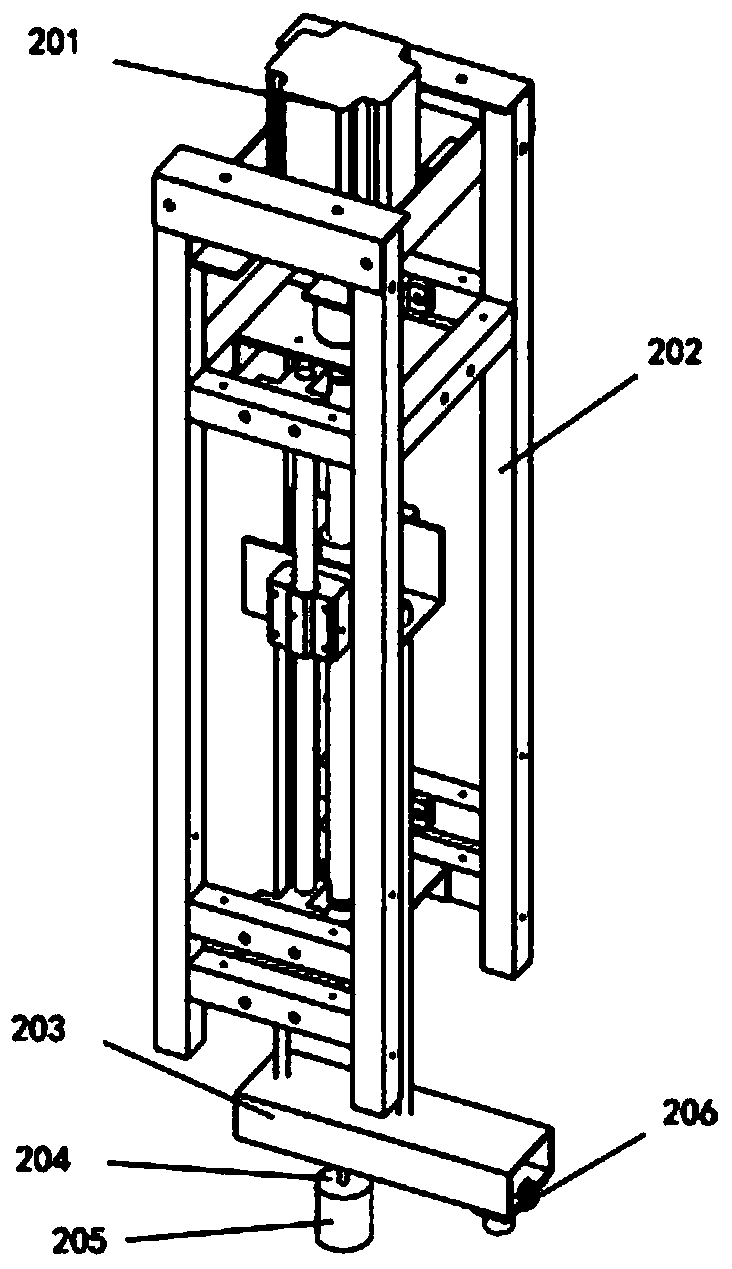

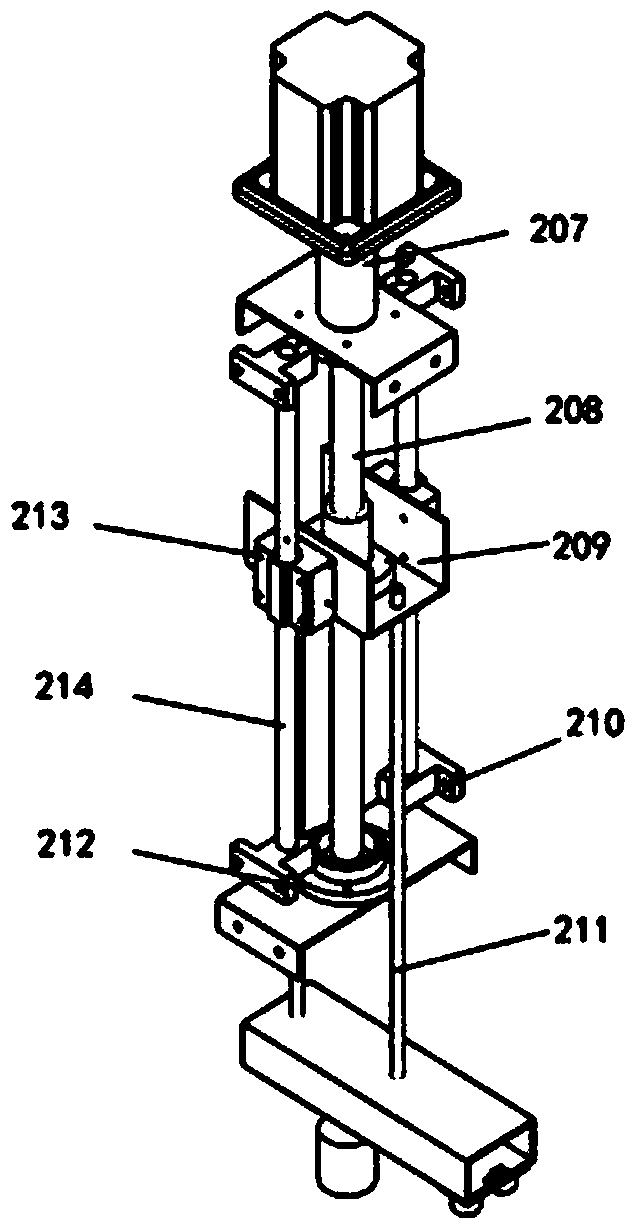

[0049]The structure of the heave compensation system actuator is as follows: it includes an external frame 202 connected to the end of the crane wire rope, and a stepping motor I201 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com