Pushing-type predeformation hydraulic cold roll forming mill

A cold forming machine and anti-deformation technology, applied in the directions of feeding device, positioning device, storage device, etc., can solve the problems of high input cost, waste of raw materials and manpower, excessive thinning of pipe wall, etc., and achieve construction adaptability. Good sex, solve the effect of serious deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

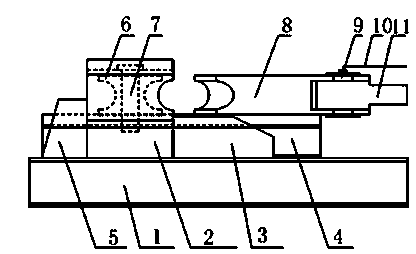

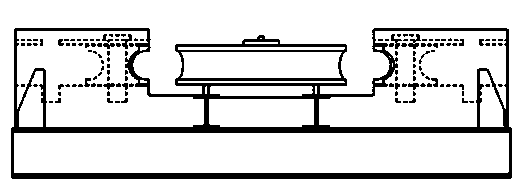

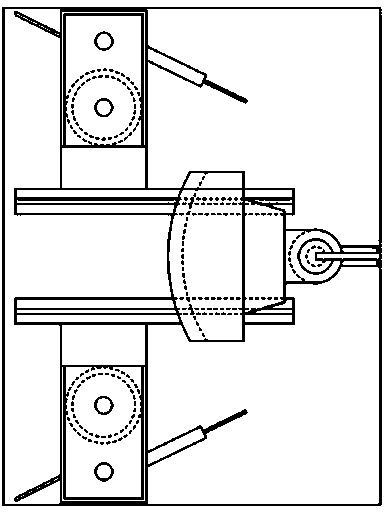

[0020] refer to Figure 1-3 As shown, the push-type anti-deformation hydraulic cold roll forming machine includes a workbench 1, an anti-deformation jacking head 8, and positioning rollers 6. The anti-deformation jacking head 8 capable of moving back and forth is arranged on the central axis of the workbench. , and two positioning rollers 6 are arranged symmetrically on both sides of the central axis, and the position of the positioning rollers on the workbench is located at both sides in front of the anti-deformation jacking head. The rear end of the anti-deformation jacking head is hinged with a hydraulic propulsion rod 11 through a connecting shaft, and the hydraulic propulsion rod is connected with a hydraulic dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com