Compound adsorbent based on hippophae rhamnoides linn branches and trunks and preparation method of compound adsorbent

A composite adsorption, sea buckthorn technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of resource waste, ecological environment damage, etc., to extend the industrial chain, reduce residues, and learn from effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation of embodiment 1 composite adsorbent of the present invention

[0044] Seabuckthorn branches are soaked in water for 24 hours, dried, crushed, and passed through a 80-mesh sieve. Weigh 10g of sieved seabuckthorn, add 10g of ZnCl according to the ratio of 1:1 2 Activated for 24h. Wash three times with distilled water, centrifuge, soak the obtained precipitate in 0.5mol·L -1 FeCl 3 solution, after 12 hours, take the precipitate and dry it in an oven at 80°C for 4 hours. The dried precipitate was placed in a single-tube carbonization furnace under N 2 Carbonization at 500°C for 1h under ambient conditions. Cool to room temperature, grind for later use, and obtain the composite adsorbent of the present invention.

Embodiment 2

[0045] Embodiment 2 Preparation of composite adsorbent of the present invention

[0046] Seabuckthorn branches are soaked in water for 24 hours, dried, crushed, and passed through a 80-mesh sieve. Weigh 10g of sieved seabuckthorn, add 10g of ZnCl according to the ratio of 1:1 2 Activated for 24h. Wash three times with distilled water, centrifuge, soak the obtained precipitate in 0.5mol·L -1 FeCl 3 solution, after 12 hours, take the precipitate and dry it in an oven at 80°C for 4 hours. The dried precipitate was placed in a single-tube carbonization furnace under N 2 Carbonization at 300°C for 1 hour under ambient conditions. Cool to room temperature, grind for later use, and obtain the composite adsorbent of the present invention.

Embodiment 3

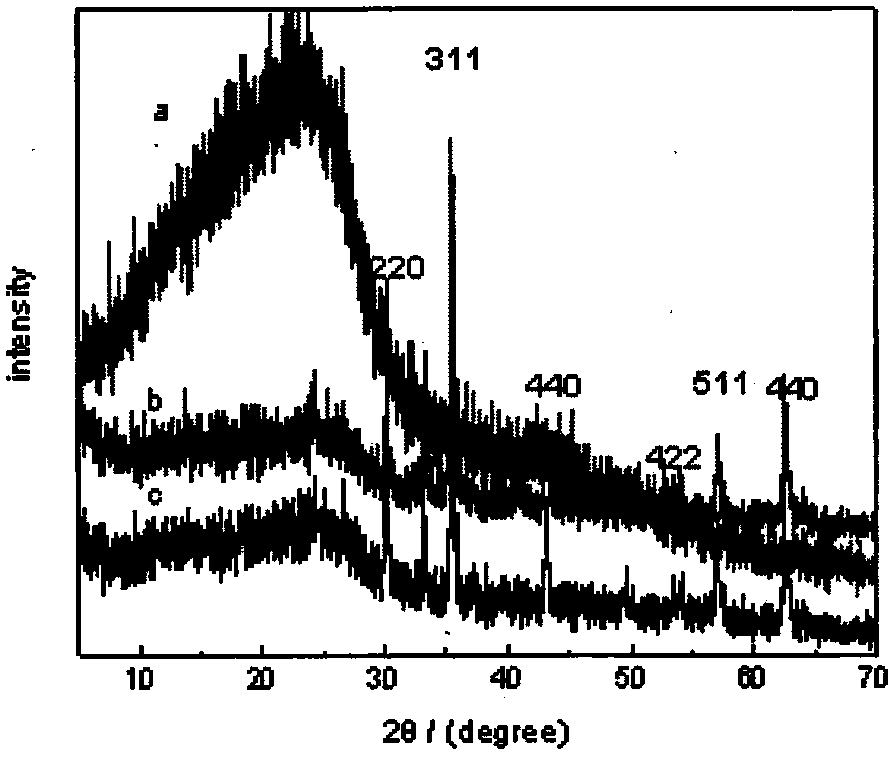

[0047] The detection of embodiment 3 composite adsorbent of the present invention

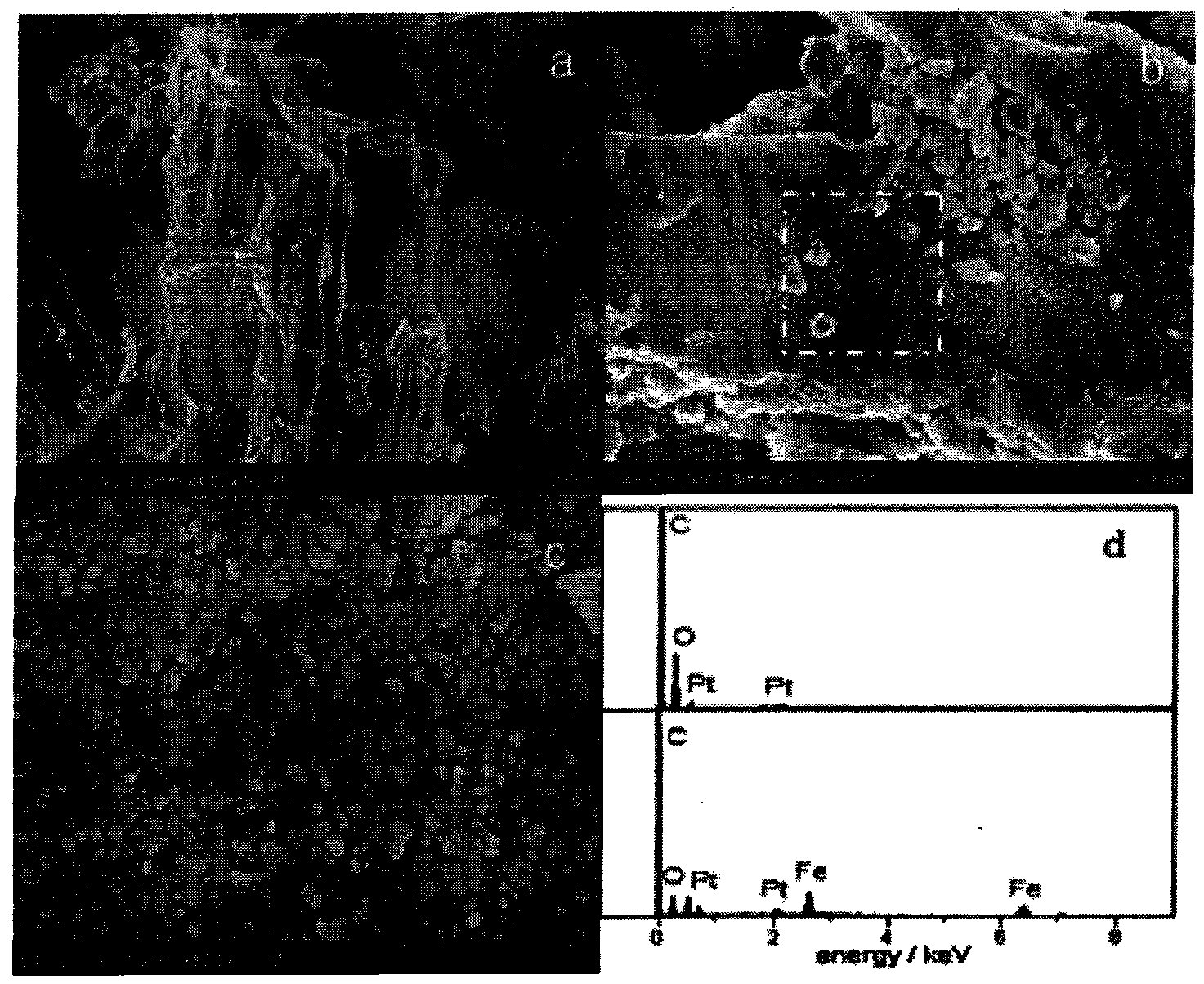

[0048] 1. SEM and EDS

[0049] SEM and EDS of seabuckthorn branch charcoal, composite adsorbent and its surface selected area as figure 1 shown.

[0050] figure 1 (a) is the SEM image of seabuckthorn branch charcoal. It can be seen from the figure that seabuckthorn branch charcoal is an irregular short rod-shaped structure with a diameter of about 7-10 μm and a rough surface. This is due to the concave-convex structure of the epidermis of seabuckthorn branches, which is very similar to the structure of biochar reported in the literature with cellulose and lignin as the main components. [6,8] . Figures (b) and (c) are SEM images of composite adsorbent products. From Figure (b), it can be clearly observed that compared with the original rough and rough surface of seabuckthorn branch charcoal, a large amount of nano-Fe 3 o 4 Particles were loaded on the outer surface of seabuckthorn branch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com