A polymer material bone plate

A polymer material and bone plate technology, applied in the direction of outer plate, internal bone synthesis, fixer, etc., can solve problems such as loss of bone reduction, restriction of polymer material bone plate, unfavorable bone 40 healing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

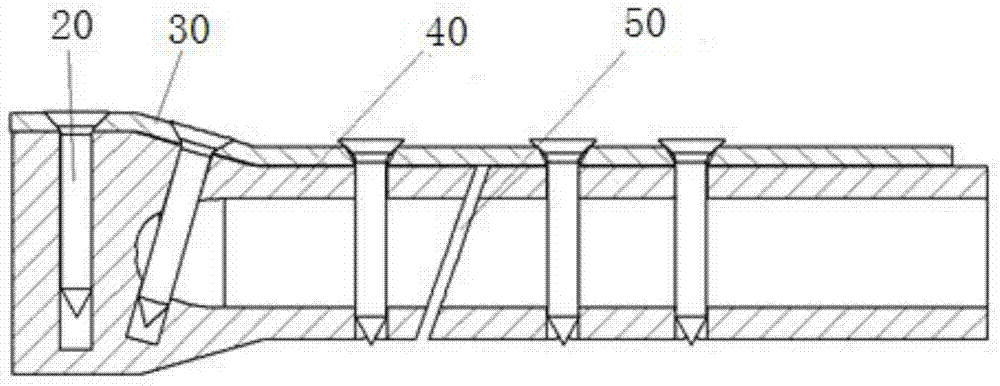

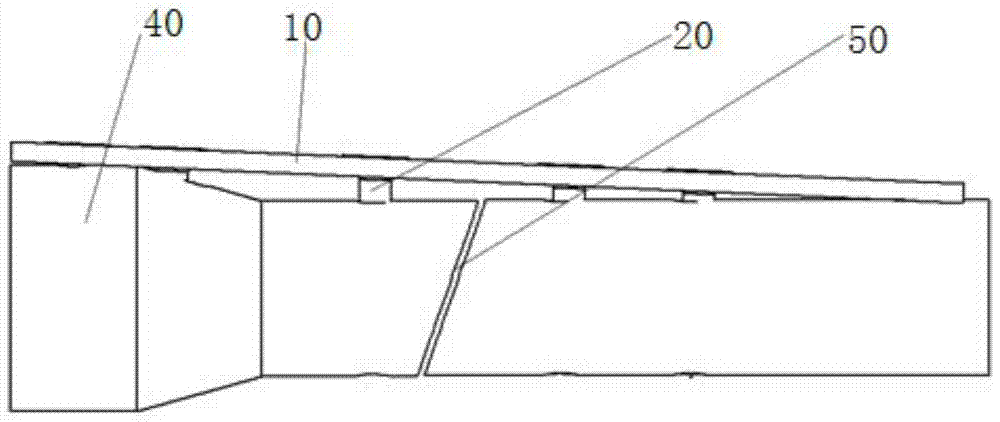

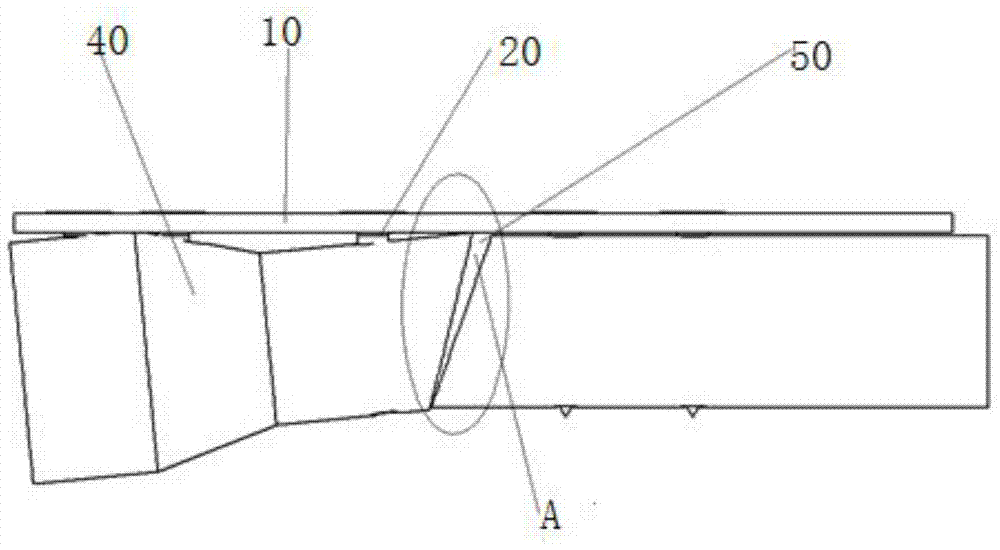

[0021] The main technical solution of the present invention is: the bone plate is formed by compounding substrates with different thicknesses and functional plates. In this way, the thinner substrate is prone to deformation, and the thicker functional plate on it can be deformed with the deformation of the substrate. Deformation, so that the polymer bone plate can be precisely shaped along the shape of the bone to ensure the reduction effect.

[0022] The technical solution of the present invention will be further described below only through the embodiments and related drawings.

[0023] Figure 2a-2b Schematic diagrams of the front and back of the polymer material bone plate provided in this embodiment, respectively. Such as Figure 2a As shown, the polymer bone plate 1 includes a base plate 11 and a functional plate 12 compositely connected thereto, wherein the thickness of the base plate 11 is smaller than that of the functional plate 12, and both the base plate 11 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com