Microbial additive for preparing silage

A technology for microbial additives and silage, applied in the field of silage, can solve the problems of large difference in effect, high cost, few types and quantities of additives, etc., and achieve the effects of reducing content, strong acid-producing ability, and prolonging shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Screening and identification of embodiment 1 Lactobacillus plantarum ZJY-6

[0021] 1. Strain screening

[0022] 1) Weigh 50 grams of corn stalks that have just been taken out from the silo, and soak them in 100 ml of sterile water for 30 minutes;

[0023] 2) Take the supernatant and dilute it 1000 times with sterile water;

[0024] 3) Primary screening: Spread the diluted supernatant evenly on the MRS plate with 0.5% calcium carbonate, culture at 37°C for 48 hours, separate and cultivate the strains with transparent circles, and obtain 12 strains of lactic acid bacteria, named ZJY-1 respectively , ZJY-2, ..., ZJY-12;

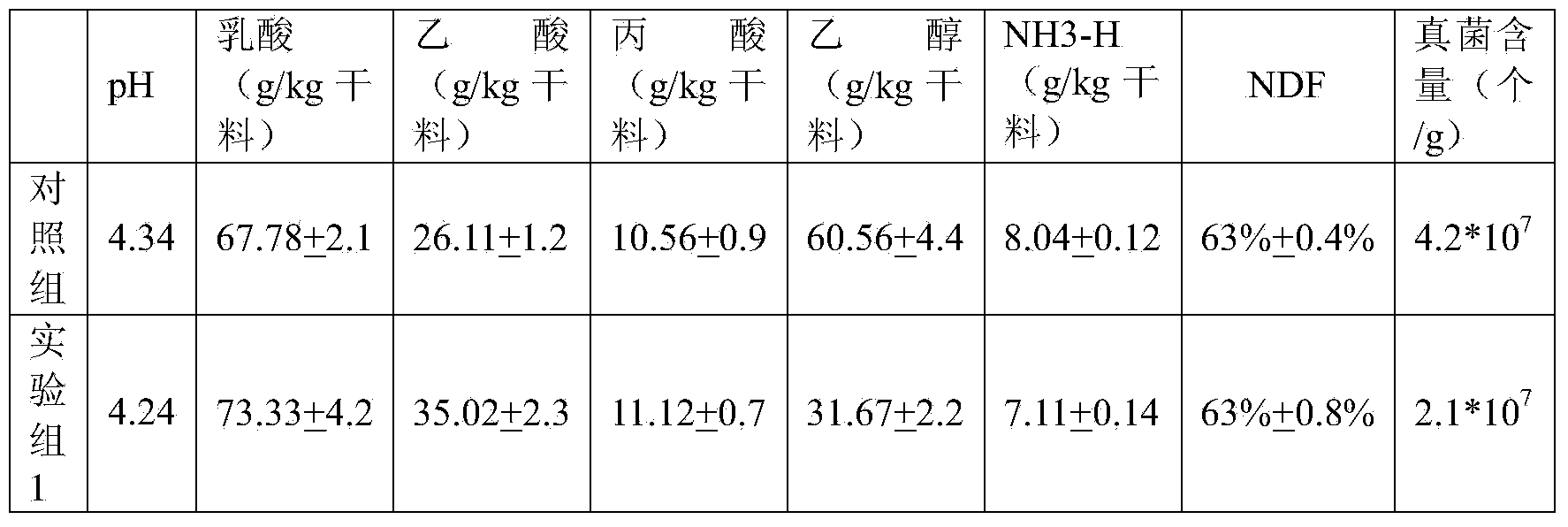

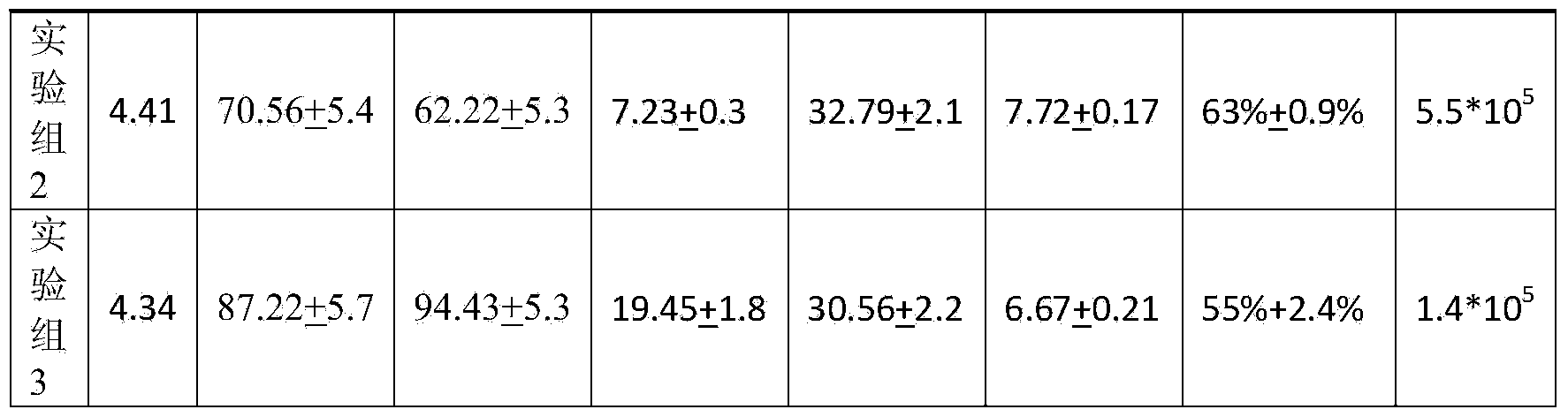

[0025] 4) Re-screening: Inoculate the above 12 strains of lactic acid bacteria into 50mL MRS broth medium respectively, culture at 37°C for 48h, measure the contents of lactic acid, acetic acid and propionic acid in the medium by HPLC, and measure the content of the medium with a pH meter. pH, the specific results are shown in Table 1.

[0026] Table...

Embodiment 3

[0032] Application of embodiment 3 Lactobacillus plantarum ZJY-6 in silage preparation

[0033] 1. Prepare microbial additive samples

[0034] 1) Sample 1: Lactobacillus plantarum ZJY-6, the concentration of live bacteria is 10 8 a / ml;

[0035] 2) Sample 2: Lactobacillus plantarum ZJY-6 and Lactobacillus Brucella were mixed at a ratio of 1:1, and the concentration of the mixed bacteria liquid was 10 8 / ml.

[0036] 3) Sample 3: Lactobacillus plantarum ZJY-6 and Lactobacillus Brucella were mixed according to the live bacteria amount of 1:1, and the concentration of the mixed bacteria solution was 10 8 / ml; cellulase 10000IU / mL, xylanase 10000IU / mL.

[0037] 2. How to use

[0038] 1) Three experimental groups: according to the addition ratio of 250-500mL / ton, spray the same amount of sample 1 (experimental group 1), sample 2 (experimental group 2) and sample 3 (experimental group 3) to 500 kg respectively On the silage raw material (what used in this embodiment is the corn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com