Drive for Switching a Double Seat Valve

A technology of a driving device and a double-seat valve, applied in the field of driving devices, can solve the problems of insufficiency, inability to provide or provide, cost, etc., and achieve the effect of expanding the installation length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

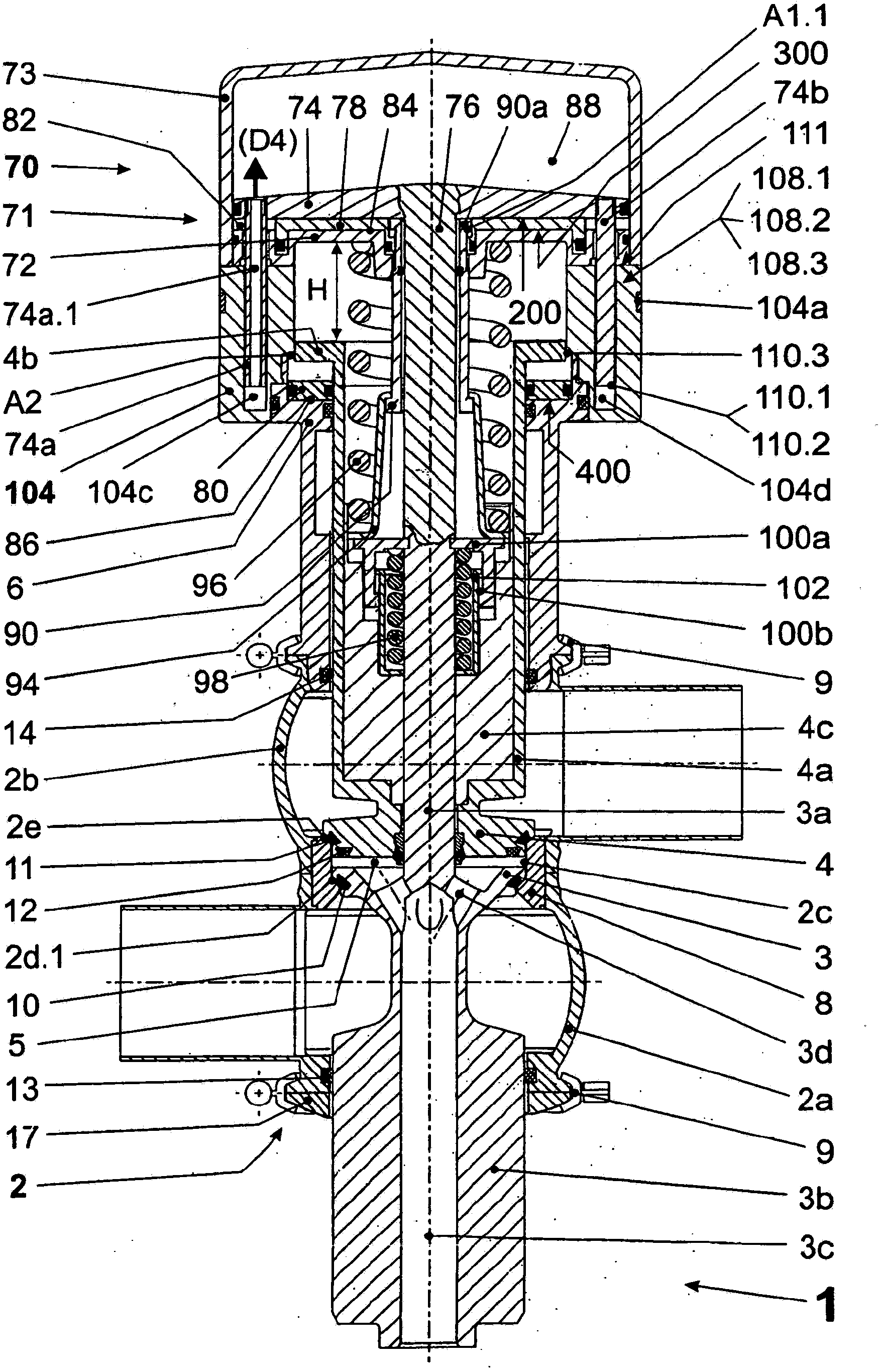

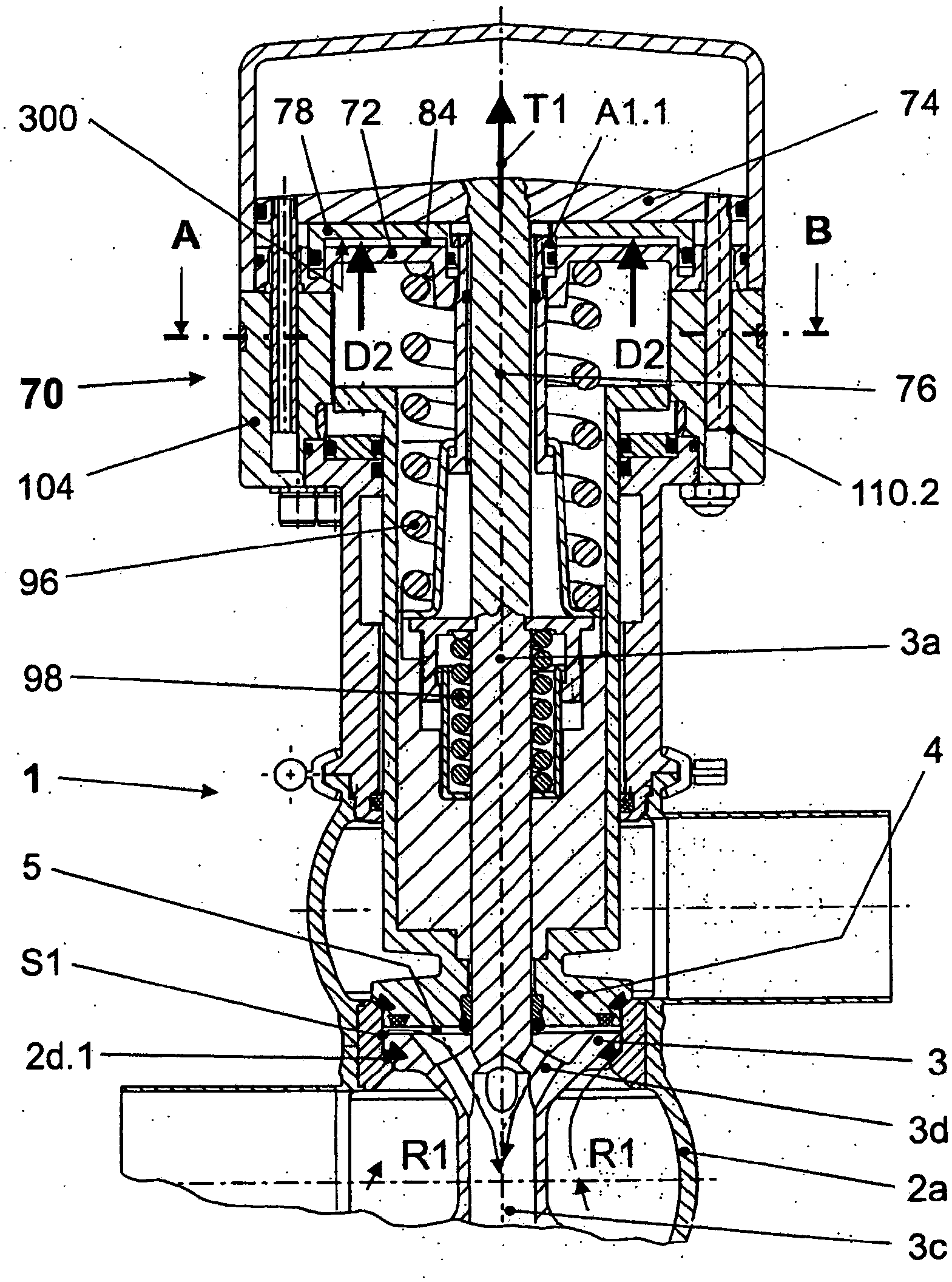

[0038] The seat-cleanable double-seat valve 1 of the second valve type is in its closed position in combination with the drive device 70 according to the invention. figure 1 shown in . The double-seat valve has two closing parts 3 , 4 arranged in series and movable relative to one another, each formed as a valve seat disc, which prevent fluid from passing through the valves in the closed position of the double-seat valve 1 . The connecting opening 2c through which the body parts 2a, 2b are connected to each other overflows from one valve body part 2a, 2b of the valve body 2 into the other valve body part 2b, 2a, and the closure is not only in the closed position but also in the open position A leakage cavity 5 connected to the environment of the double-seat valve 1 is defined therein. The leakage chamber 5 is connected to the environment via at least one connection opening 3 d in the first closing part 3 , which opens into an outlet opening 3 c of a tube shaft 3 b arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com