A kind of flexible packaging bag

A flexible packaging bag and main body technology, which is applied in the field of flexible packaging bags, can solve problems such as the difficulty in realizing quantitative access and the inability to form a stable metering space and flow channel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

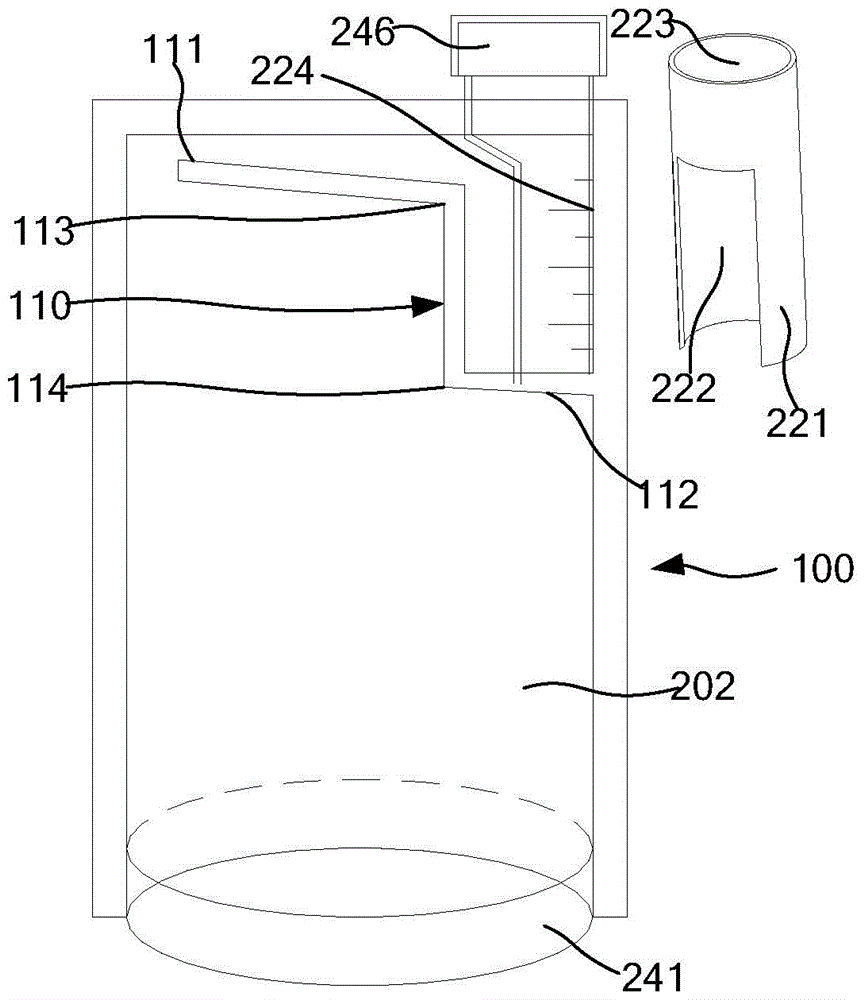

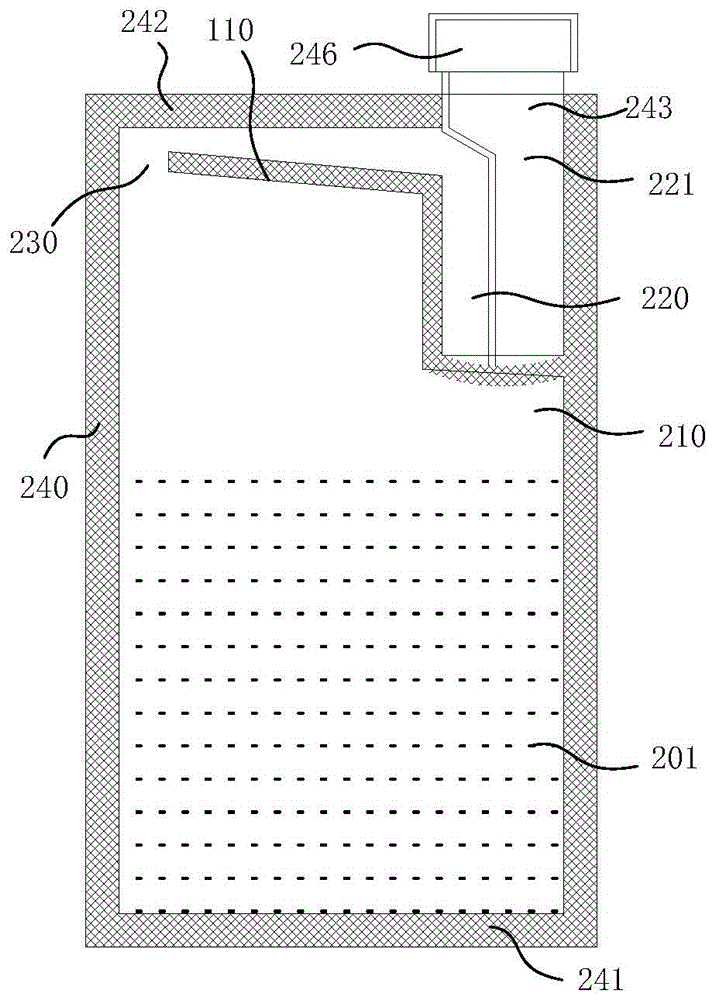

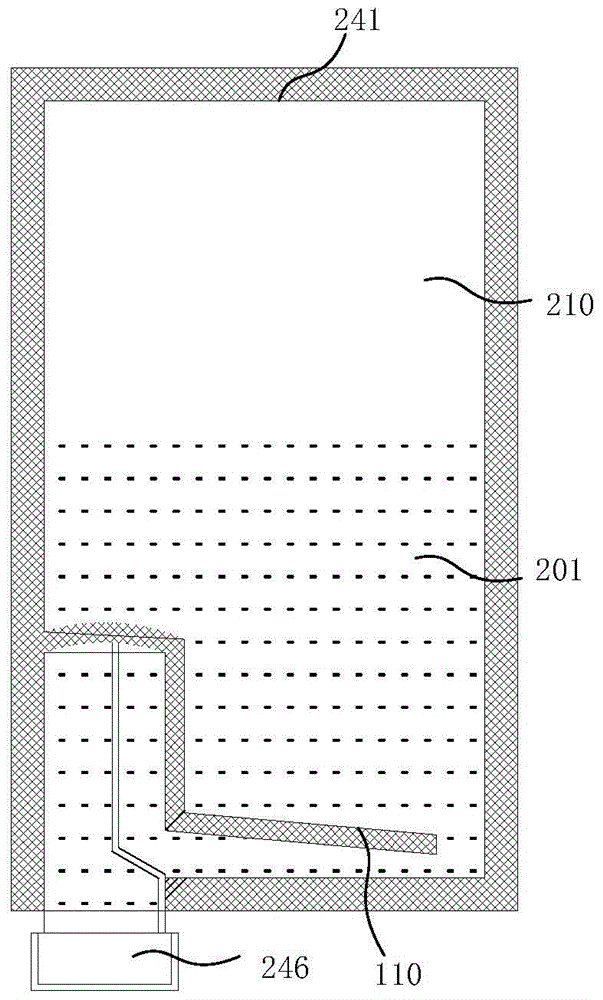

[0076] Such as Figure 1-1 to Figure 1-5 As shown, the main body 100 of the flexible packaging bag in this embodiment is surrounded by the flexible packaging bag wall 202 by means of heat sealing, pressing or bonding to form an inner space, and the sealing part forms the sealing edge of the flexible packaging bag, including the soft packaging bag The side sealing edge 240, the upper sealing edge 242 of the flexible packaging bag and the lower sealing edge 241 of the flexible packaging bag form an internal space including a storage chamber 210, a temporary storage chamber 220 for temporarily storing materials, and a storage chamber 210 connected to the temporary storage chamber. The channel 230 of the storage cavity 220, the temporary storage cavity 220 and the storage cavity 210 are respectively arranged above and below the flexible packaging bag main body 100, and the part of the packaging bag inner wall of the flexible packaging bag main body 100 closely fits forms the gap be...

Embodiment 2

[0082] Such as Figures 2-1 to 2-13 As shown, a flexible packaging bag includes a flexible packaging bag main body 100, a top sealing edge 242, a bottom edge 241, a side edge 240 and a hard measuring bucket 30. The flexible packaging bag main body 100 has a storage cavity 210, a top sealing edge 242 and a bottom sealing edge The sides 241 are respectively located at the top and bottom of the main body 100 of the soft packaging bag. The measuring bucket 30 includes a connected temporary storage chamber 220 and a drain pipe 303. The drain pipe 303 is fixed or movable on the opening 243 of the top sealing edge 242. The temporary storage chamber 220 is located in the storage chamber 210, and the upper edge of the temporary storage chamber 220 is provided with a passage 230, and the passage 230 is located between the temporary storage chamber 220 and the discharge pipe 303, that is, between the temporary storage chamber 220 and the discharge pipe 303. On one side of the joint, the ...

Embodiment 3

[0090] As shown in Figures 3-1 to 3-18, a flexible packaging bag differs from Embodiment 2 in that it further includes a clip 50, and the clip 50 is provided with clip teeth 501 and recessed parts 502.

[0091] When the flexible packaging bag is used for the first time, the flexible packaging bag main body 100 and the measuring bucket 30 are separated, and the flexible packaging bag main body 100 is provided with a pre-opening 244. When the flexible packaging bag is used for the first time, the pre-opening 244 needs to be torn to form a flexible packaging bag The opening 243 of the main body 100 .

[0092] Similar to Embodiment 1, at the position where the outer wall of the drain pipe 303 is combined with the top sealing edge 242, corresponding to the directions A and B, there are respectively a first directional joint position 301 and a second joint position 301 with different sizes and / or shapes. The two directional joints 302 , the first directional joint 301 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com