Electronically controlled dimming film

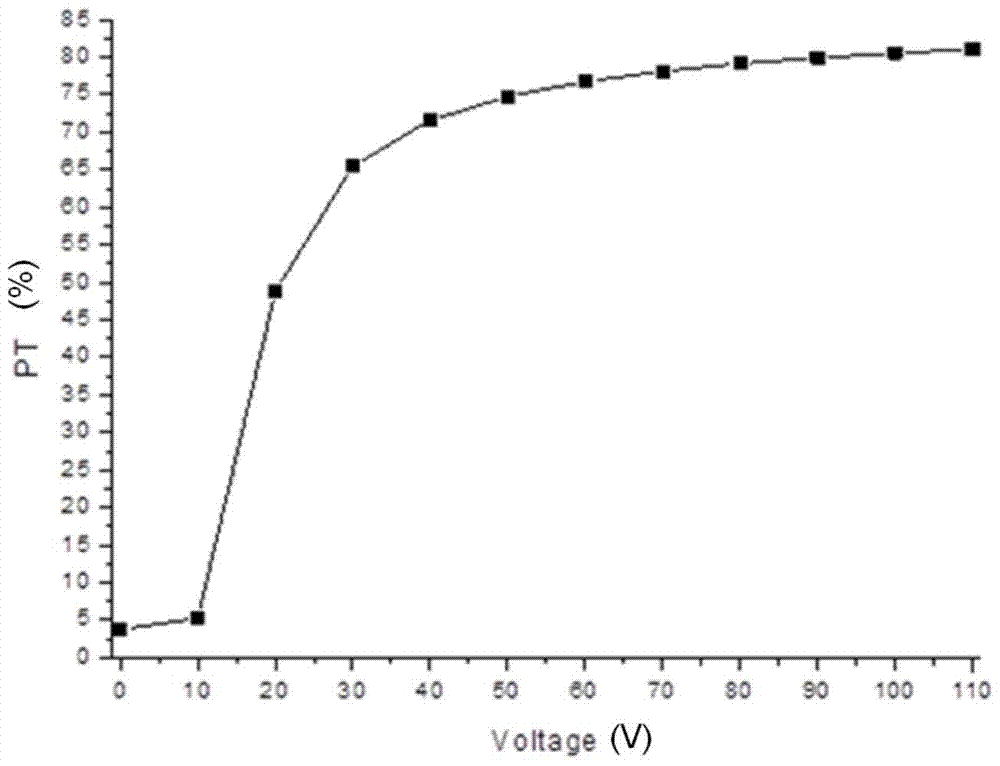

A dimming film and electronic control technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of low open-state transmittance and high driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

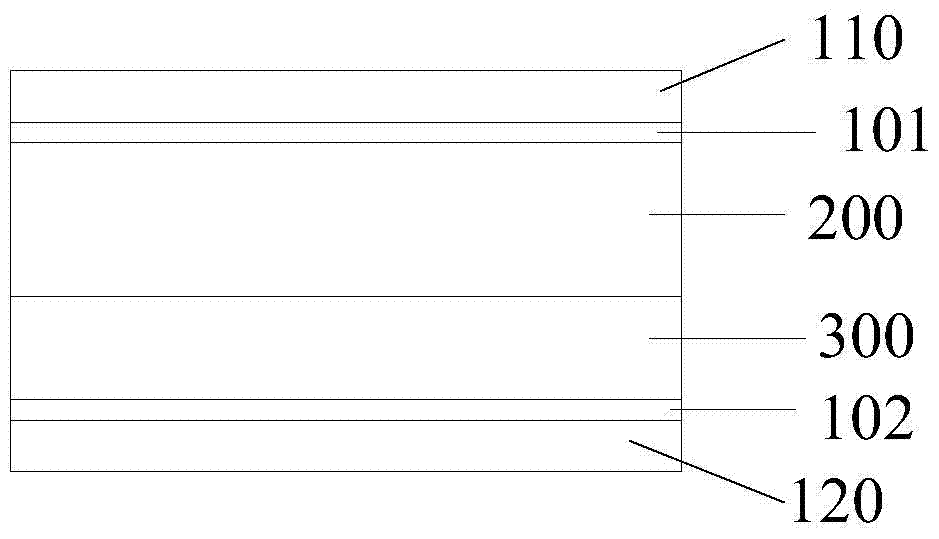

Method used

Image

Examples

Embodiment 1

[0052] In this embodiment, an electronically controlled dimming film is prepared, and its preparation method is as follows:

[0053] (1) Fix the single piece of ITO film on the semi-automatic coating machine, pay attention to the transparent conductive layer upward; secondly, drop the prepared electrochromic layer to be cured slurry evenly on the fixed end of the ITO film, and then start the semi-automatic coating The cloth machine uses wire rods of models 1 to 10 to control the layer thickness, and the coating is completed at a uniform speed at a speed of 1m / min. Finally, it passes through a UV curing machine and is cured by UV light to form an electrochromic layer.

[0054] (2) Fix the single piece of ITO film on the semi-automatic coating machine, pay attention to the transparent conductive layer upward; secondly, the previously prepared polymer dispersed liquid crystal layer to be cured slurry, evenly dripped on the fixed end of the ITO film, and then start the semi-automat...

Embodiment 2

[0061]In this example, an electronically controlled dimming film is prepared. The preparation method is the same as in Example 1, except that, before coating the electrochromic layer and the polymer-dispersed liquid crystal layer, two ITO films are coated with epoxy Resin anti-corrosion layer.

[0062] The raw material components and consumption of the polymer dispersed liquid crystal layer and the raw material components and consumption of the electrochromic layer are as follows:

[0063]

[0064] The above-mentioned liquid crystal has a molecular weight of 420, a refractive index of 1.486, a dielectric coefficient of 13, a clearing point of 85°C, an optical anisotropy Δn of 0.246, and a viscosity of 92; the square resistance of the ITO film is 75Ω / port, and the transmittance is 86.9%, haze value <1.7%.

Embodiment 3

[0066] In this example, an electronically controlled dimming film is prepared. The preparation method is the same as in Example 1, except that, before coating the electrochromic layer and the polymer-dispersed liquid crystal layer, two ITO films are coated with epoxy Resin anti-corrosion layer.

[0067] The raw material components and consumption of the polymer dispersed liquid crystal layer and the raw material components and consumption of the electrochromic layer are as follows:

[0068]

[0069]

[0070] The above-mentioned liquid crystal has a molecular weight of 380, a refractive index of 1.525, a dielectric coefficient of 15, a clearing point of 95°C, an optical anisotropy Δn of 0.219, and a viscosity of 84; the square resistance of the ITO film is 155Ω / port, and the transmittance is 90%, haze value <1.55%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| isotropization temperature | aaaaa | aaaaa |

| isotropization temperature | aaaaa | aaaaa |

| isotropization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com