Load test board with sail stress simulation function

A technology of loading test and test bench, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc. It can solve the problems of long test period, high cost, poor real-time performance, etc., and achieve complete functions and fast response , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

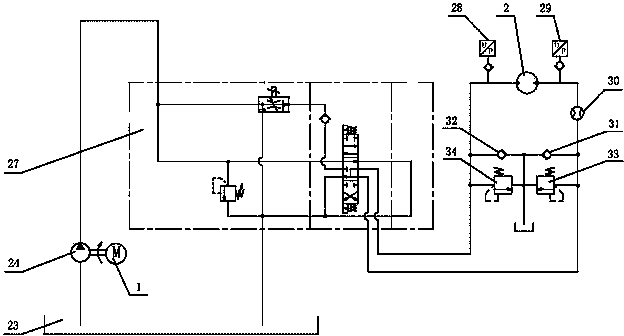

[0025] see figure 1 and figure 2 , a loading test bench for simulating the force of a sail of the present invention, its mechanical hardware consists of a test bench base 10, a fuel tank 23, an electric motor 1, a low-speed high-torque motor 2, a pinion 7, a large gear 20, and a first gear shaft 6 , the second gear shaft 21, the first bearing and the bearing seat 5, the second bearing and the bearing seat 8, the third bearing and the bearing seat 19, the fourth bearing and the bearing seat 22, the reducer 16, the first shaft coupling 4, The second coupling 18 , the third coupling 15 , the fourth coupling 13 , the magnetic powder brake 12 , the encoder 9 and the torque sensor 14 . Both the oil tank 23 and the motor 1 are installed on the test bench base 10, the low-speed high-torque motor 2 is installed on the test bench base 10 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com