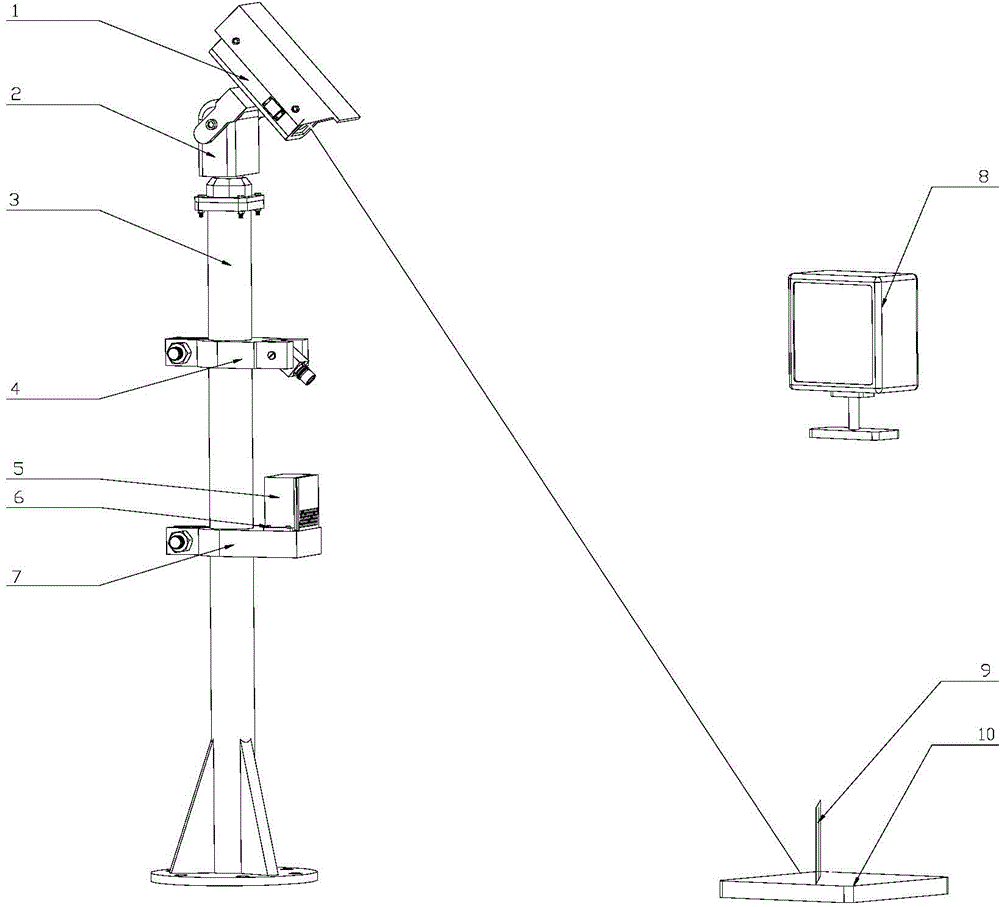

Laser and video infused automatic railway snow depth multi-point measuring device and method

A technology of video fusion and automatic measurement, applied in the direction of measuring devices, optical devices, rainfall/precipitation gauges, etc., can solve the problems of data observation point abolishment, wrong train scheduling, short measurement distance, etc., and achieve simple structure and improved Measurement accuracy, real-time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The present invention is based on the multi-point automatic measurement method of railway snow depth of laser snow depth sensor and network camera, comprises the following steps:

[0054] The first step is to set a vertical line at the longitudinal center of the straight snow measuring ruler 9, and the scale line is perpendicular to the vertical line to form the intersection point of the cross line. The number of intersection points is set as n, and the division value is m Indicates that the total length of the snow measuring stick is L;

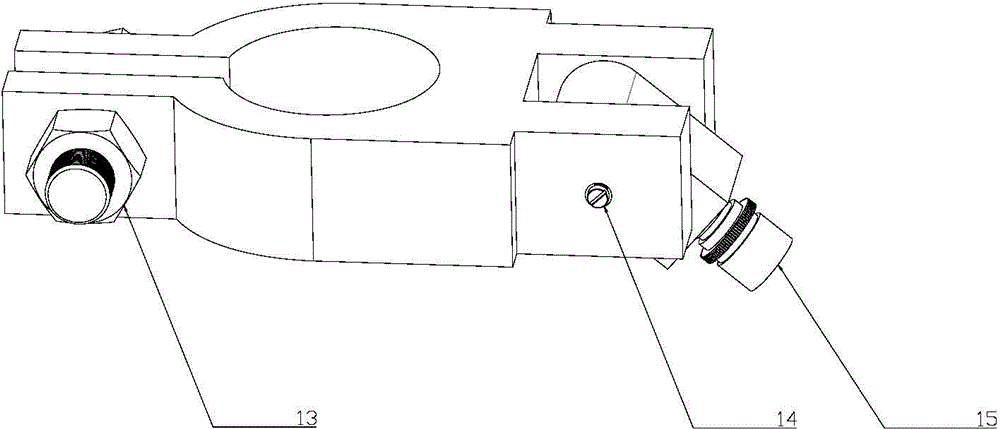

[0055] The 2nd step, obtain the snow-measuring ruler 9 image that network camera 15 gathers before snow accumulation, determine the image of snow-measuring ruler 9 and the ratio relation of actual snow-measuring ruler 9, denoted as 1:λ;

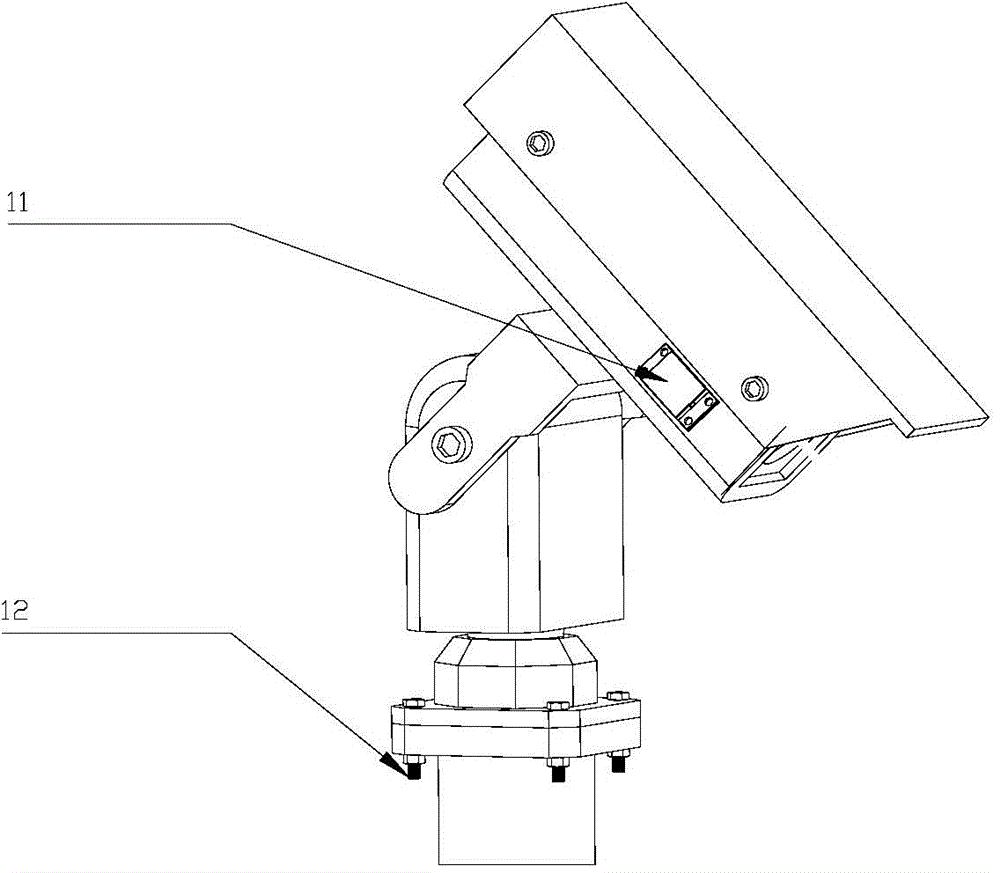

[0056] The third step is to adjust the rotation angle of the cloud platform 2 so that the laser snow depth sensor 1 and the snow measuring ruler 9 measure the snow depth value at the same point, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com