Trajectory slideway-type pressure relief switch

A slideway and trajectory technology, which is applied in the direction of wellbore/well components, earthwork drilling and production, sealing/isolation, etc., can solve the problems of construction failure and easy upward string movement of tubing, and achieve unique trajectory design and avoid radial The effect of exposed vias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

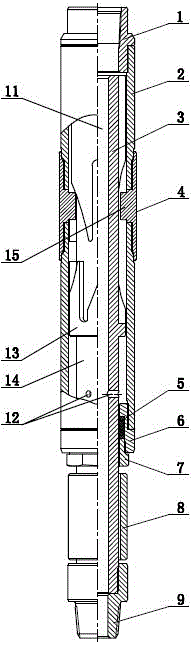

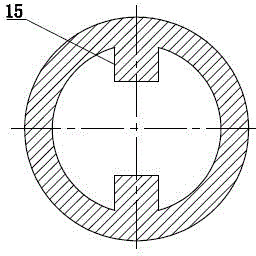

[0027] As shown in the figure, the track slideway pressure relief switch includes an outer sleeve 2 and a track core tube 3 arranged in the outer sleeve 2. The number of the outer sleeves 2 is two, and a slide is used between the two outer sleeves 2 The column collar 4 is connected and fixed, the upper end of the upper outer casing 2 is threaded with the upper joint 1, the lower end of the lower outer casing 2 is threaded with the lower collar 6, and the track core pipe 3 is composed of the upper thick-diameter cylindrical section 13 and the lower Small-diameter cylindrical section 14 is composed of an axial through hole 11 in the middle, and a plurality of radial through-holes 12 communicating with the axial through-hole 11 are provided on the lower thin-diameter cylindrical section 14. The lower end of the section 14 protrudes to the outside of the lower collar 6 and an annular seal 5 is arranged between the inner ring groove of the lower collar 6 and the lower thin-diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com