Liquid multi-dyeing auxiliary agent and using method thereof

A technology of liquid multi-combination and auxiliaries, which is applied in the field of textile dyeing, can solve the problems of large difference between hue and soda ash, a large number of color differences, and affect the quality of printing and dyeing, so as to reduce the adsorption and diffusion time, save energy consumption and workload, The effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

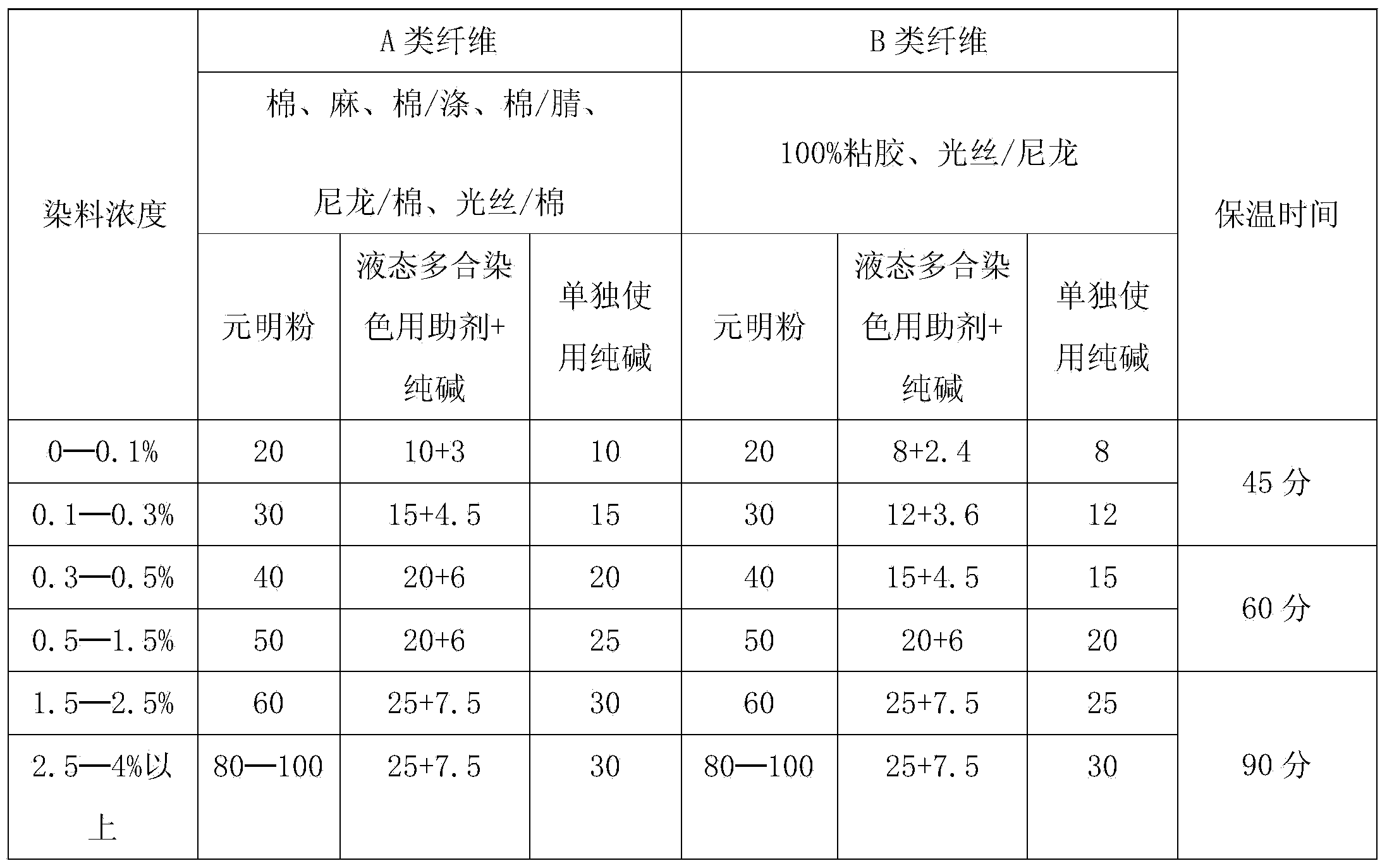

Image

Examples

Embodiment 1

[0039] A kind of auxiliary agent for liquid polydye dyeing provided by this embodiment, the auxiliary agent for liquid polydye dyeing is the aqueous solution of flaky sodium hydroxide, chelating agent and sodium hexametaphosphate, the pH of the auxiliary agent for liquid polydye dyeing The value is 2g / L: 8.5±1, where;

[0040] Sodium hydroxide, sodium salt, chelating agent and sodium hexametaphosphate are respectively in parts by mass:

[0041]Sodium hydroxide: 1 part, chelating agent: 0.2 part, sodium hexametaphosphate: 0.5 part, the mass ratio of the total mass of sodium hydroxide, chelating agent and sodium hexametaphosphate to water is 2:50.

Embodiment 2

[0043] A kind of auxiliary agent for liquid polydye dyeing provided by this embodiment, the auxiliary agent for liquid polydye dyeing is the aqueous solution of flaky sodium hydroxide, chelating agent and sodium hexametaphosphate, the pH of the auxiliary agent for liquid polydye dyeing The value is 2g / L: 8.5±1, where;

[0044] Sodium hydroxide, sodium carbonate, chelating agent and sodium hexametaphosphate are respectively in parts by mass:

[0045] Sodium hydroxide: 1.5 parts, chelating agent: 0.5 part, sodium hexametaphosphate: 1 part, the mass ratio of the total mass of sodium hydroxide, chelating agent and sodium hexametaphosphate to water is 2:50.

Embodiment 3

[0047] The aforementioned liquid multi-dyeing auxiliary agent provided in this embodiment is an aqueous solution of flaky sodium hydroxide, a chelating agent and sodium hexametaphosphate, and the liquid multi-dyeing auxiliary agent is The pH value is 2g / L: 8.5±1, where;

[0048] Sodium hydroxide, sodium carbonate, chelating agent and sodium hexametaphosphate are respectively in parts by mass:

[0049] 1 part of sodium hydroxide, 0.2 part of chelating agent, 0.2 part of sodium hexametaphosphate, the mass ratio of the total mass of sodium hydroxide, chelating agent and sodium hexametaphosphate to water is 2:50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ph value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com