After-printing washing process

A post-printing and process technology, which is applied in the field of post-printing washing process, can solve the problems of high bath ratio, large amount of wastewater discharge and large consumption in the production process, and achieve the control of reducing energy consumption, reducing sewage discharge and improving energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

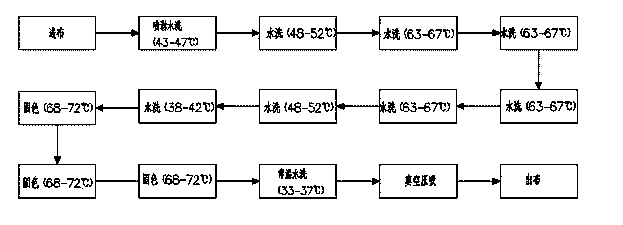

[0013] see figure 1 , a washing process for extra dark swimming cloth after printing, including the following steps: (1) Gray cloth enters the first washing tank at a speed of 12m / min, replenishes water with 15L / kg gray cloth, and sprays and washes it with water at 46°C Then enter the second washing tank, add soda ash to adjust the pH value to 11.1, add 2.2 parts of CD anti-staining agent, and wash with 52°C water; (2) Gray cloth enters the third washing tank, add water 10L / kg gray cloth, use 67 After washing with water at ℃, enter the fourth washing tank, add 2.5 parts of CD anti-stick agent, and wash with water at 63-67 °C; (3) gray cloth enters the fifth washing tank, add soda ash to adjust the pH value to 11.1, and use After washing with water at ℃, enter the sixth washing tank, and wash with water at 67 °C; (4) gray cloth enters the seventh washing tank, add 3 parts of CD anti-sticking agent, wash with water at 52 °C, and then enter the eighth washing tank tank, add wate...

Embodiment 2

[0015] see figure 1 , a washing process for medium-dark swimming cloth after printing, including the following steps: (1) The gray cloth enters the first washing tank at a speed of 15m / min, replenishes water with 14L / kg gray cloth, and sprays and washes it with water at 45°C Then enter the second washing tank, add soda ash to adjust the pH value to 11.0, add 2.0 parts of CD anti-stain agent, and wash with water at 50°C; (2) The gray cloth enters the third washing tank, replenishing water 9L / kg gray cloth, use 65 After washing with water at ℃, enter the fourth washing tank, add 2.0 parts of CD anti-stain agent, and wash with water at 65 °C; (3) gray cloth enters the fifth washing tank, add soda ash to adjust the pH value to 11.0, and use After washing with water, enter the sixth washing tank and wash with water at 65°C; (4) Gray cloth enters the seventh washing tank, add 2 parts of CD anti-staining agent, wash with 450°C water and then enter the eighth washing tank, Water 7L / k...

Embodiment 3

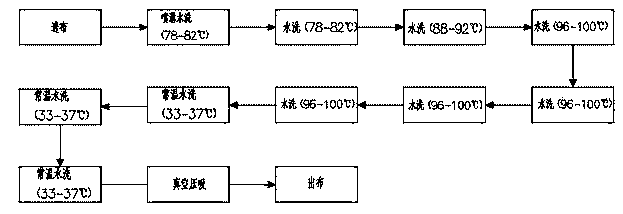

[0017] see figure 1 , a washing process for light-colored swimming cloth after printing, including the following steps: (1) Gray cloth enters the first washing tank at a speed of 18m / min, replenishes water with 13L / kg gray cloth, sprays and washes it with water at 44°C Enter the second washing tank, add soda ash to adjust the pH value to 10.9, add 1.8 parts of CD anti-staining agent, and wash with water at 48°C; After washing with water, enter the fourth washing tank, add 1.5 parts of CD anti-stain agent, and wash with water at 63°C; (3) Gray cloth enters the fifth washing tank, add soda ash to adjust the pH value to 10.9, and wash with water at 63°C After washing, enter the sixth washing tank and wash with water at 63°C; (4) Gray cloth enters the seventh washing tank, add 1 part of CD anti-sticking agent, wash with 48°C water, then enter the eighth washing tank, replenish water 5L / kg gray cloth, wash with water at 38°C; (5) Gray cloth enters the ninth washing tank, add aceti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com