Automatic cutting machine and cutting method thereof

A cutting method and cutting machine technology, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of cost increase, cut protective layer, and consistent thickness of the protective layer, so as to avoid contact damage, complete cutting, and improve cutting effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

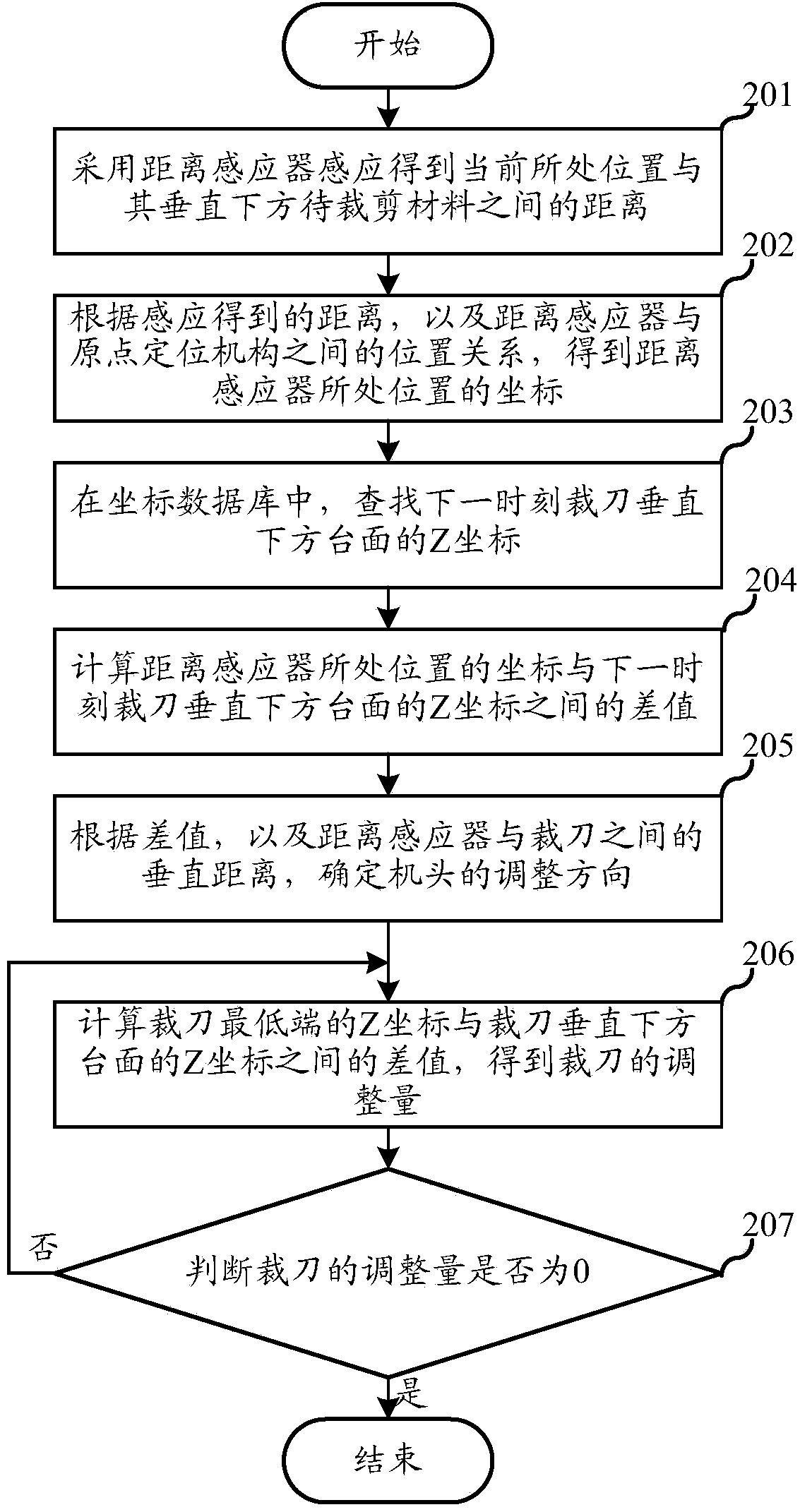

[0083] Assume that the cutter will go to the XY coordinates at the next moment (X i ,Y i+1 ), then find the Z coordinate of the corresponding table surface as Z m+1 . Subtract the Z coordinate of the current position of the cutter from the Z coordinate of the lower table corresponding to the cutter at the next moment, and the difference obtained is Z m+1 -Z m , then the calculation method of the adjustment direction and adjustment amount of the machine head is similar to that of the first embodiment:

[0084] If Z m+1 -Z m If it is less than 0, the machine head is adjusted downward, and the adjustment amount is Z m -Z m+1 ;

[0085] If Z m+1 -Z m If it is equal to 0, the machine head does not need to be adjusted;

[0086] If Z m+1 -Z m If it is greater than 0, the machine head is adjusted upwards, and the adjustment amount is Z m+1 -Z m .

[0087]The division of steps in the above methods is only for the sake of clarity of description. During implementation, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com