A method for treating electroplating wastewater

A technology for electroplating wastewater and wastewater, applied in metallurgical wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of high operating costs, large area, secondary pollution, etc. The effect of land area, reduction of industrial COD and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for treating electroplating wastewater, comprising the steps of:

[0023] 1) The electroplating wastewater passes through the grid to remove large solid matter, and then the wastewater is discharged into the sedimentation tank and left to stand for 24 hours. The bottom filler of the sedimentation tank is river sand with a thickness of 100cm, and the particle size of the river sand is 1mm. Preliminary adsorption and precipitation of metal debris and colloidal flocs can be carried out;

[0024] 2) Discharge the wastewater into the complexing tank, add complexing agent according to the ratio of 1 kg complexing agent: 1 ton of wastewater, then stir at 200 rpm for 30 minutes, and then let it stand for 6 hours; among them, the complexing agent It is prepared according to the following method: according to the mass ratio of 1:1:2:4:5, aluminum oxide, potassium humate, diatomaceous earth, ferrous sulfate, polysilicate iron (PSF, Si / Fe molar ratio is 1 ), mixed and sti...

Embodiment 2

[0029] A method for treating electroplating wastewater, comprising the steps of:

[0030] 1) The electroplating wastewater passes through the grid to remove large solid matter, and then the wastewater is discharged into the sedimentation tank and left to stand for 24-48 hours. The bottom filler of the sedimentation tank is river sand with a thickness of 100cm, and the particle size of the river sand is 2mm, for preliminary adsorption and precipitation of metal debris and colloidal flocs;

[0031] 2) Discharge the wastewater into the complexing tank, add complexing agent according to the ratio of 1 kg complexing agent: 1 ton of wastewater, then stir at 300 rpm for 60 minutes, and then let it stand for 8 hours; among them, the complexing agent It is prepared according to the following method: according to the mass ratio of 1:1:2:4:5, aluminum oxide, potassium humate, diatomaceous earth, ferrous sulfate, polysilicate iron (PSF, Si / Fe molar ratio is 0.5 ), mixed and stirred;

[...

Embodiment 3

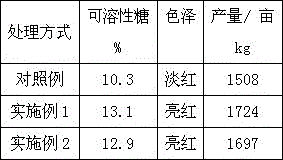

[0041] The effect of the bacterial fertilizer prepared by Example 1 or 2 of the present invention on strawberry yield and quality. The experimental variety is Fengxiang. Both Example 1 and 2 applied 100 kg / mu of bacterial fertilizer prepared by the present invention, and 100 kg / mu of commercially available Shandong Luzhuang bio-organic fertilizer was used in the comparative example, and conventional cultivation was carried out in protected land. The results are shown in Table 1. Compared with the commercially available bio-organic fertilizer, this product can increase the sugar content of strawberries, improve the color and increase the yield.

[0042] Table 2 The impact of this product on strawberry quality and yield

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com