Device and method for hoisting round mold of vulcanization tank

A hoisting device and vulcanization tank technology, which is applied in the direction of transportation and packaging, load hanging components, trolley cranes, etc., can solve problems such as waste of space, unsafe and reliable, and safety production accidents, and achieve a compact overall structure and improve production efficiency , Reliable hoisting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

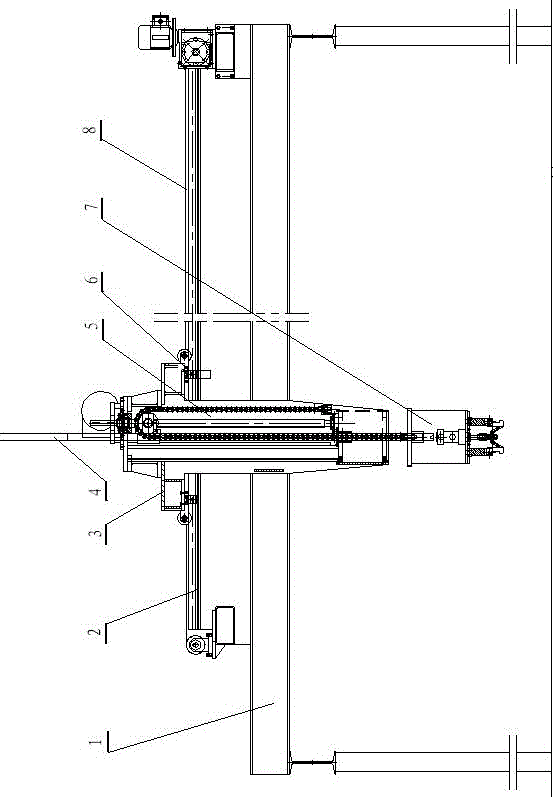

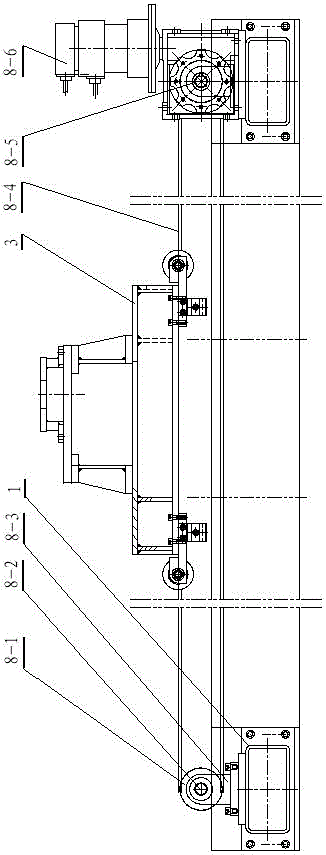

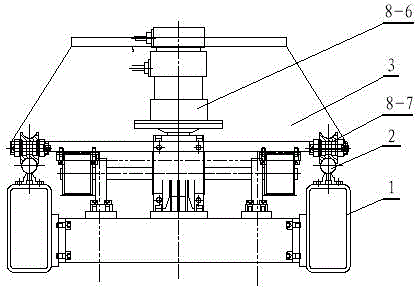

[0027] Such as figure 1 As shown, a vulcanization tank round mold lifting device includes a frame 1, a trolley 3 and an end effector 7. Two guide rails 2 for sliding the trolley 3 are provided on the beam of the frame 1, and the bottom of the trolley 3 is provided with Four pulleys 8-7 that cooperate with the corresponding guide rails 2 respectively, the frame 1 is provided with a traveling mechanism 8 that drives the trolley 3 to move horizontally along the guide rail 2, and the frame 1 is provided with a mechanism that enables the trolley 3 to stop at the corresponding production station The positioning device 6, the trolley 3 is provided with a lifting mechanism 5 that drives the end effector 7 below it to move up and down, and the lifting mechanism 5 is provided with a guide mechanism 4 that guides the end effector 7 to go up and down. 4 adopts a non-telescopic structure, and the end effector 7 is driven by an electric or pneumatic device.

[0028] In this example, if F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com