Highly-applicable rolled steel conveying device matched with conveying height

A conveying device and steel technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of difficulty in meeting different feeding heights or welding heights, multi-labor, poor practicability, etc., to achieve stable and reliable lifting and conveying, and reduce labor. The effect of improving strength and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

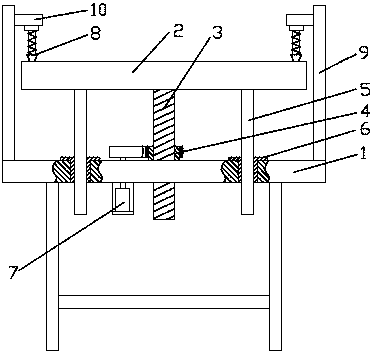

[0010] figure 1 It shows the highly applicable steel conveying device with matching conveying height provided by the present invention, including a support base 1, a jacking platform 2, and a screw 3, one end of the screw 3 is detachably connected to the jacking platform 2, and the other end is sleeved with a nut 4 And be threadedly connected with support base 1; Support base 1 is provided with motor 7, and the output shaft of motor 7 is connected with nut 4 belt drive, and nut 4 is overcoated with pulley; Support base 1 is provided with two guide holes, and the guide hole is provided with There is a bushing 6; the jacking platform 2 is detachably connected with two guide rods 5 respectively extending into the bushing 6; the support seat 1 is provided with a positioning rod 9, and the positioning rod 9 is detachabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com