Moving type automatic-adjustment steel jacking and pushing device

An automatic adjustment and push device technology, applied in the direction of lifting devices, auxiliary devices, lifting frames, etc., can solve the problems of difficulty in meeting different feeding heights or welding heights, poor practicability, and many labors, etc., to achieve stable and reliable jacking and conveying. Accurate height and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

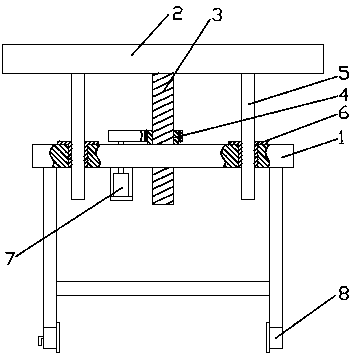

[0010] figure 1 Shown is the mobile self-adjusting steel jacking and pushing device provided by the present invention, which includes a support base 1, a jacking platform 2, and a screw 3. One end of the screw 3 is fixedly connected to the jacking platform 2, and the other end is sleeved with a nut 4 and It is threadedly connected with the support base 1; the support base 1 is provided with a motor 7, the output shaft of the motor 7 is connected to the nut 4 by belt transmission, and the nut 4 is covered with a pulley; the support base 1 is provided with two guide holes, and the guide holes are provided with The bushing 6; the jacking platform 2 is connected with two guide rods 5 respectively extending into the bushing 6; the bottom of the support seat 1 is connected with a roller 8 with a brake plate.

[0011] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com