Steel jacking and conveying device

A conveying device and jacking technology, which is used in lifting devices, auxiliary devices, transportation and packaging, etc., can solve the problems of difficulty in meeting different feeding heights or welding heights, multi-labor, poor practicability, etc., and achieve stable and reliable lifting and conveying. , the effect of reducing labor intensity and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

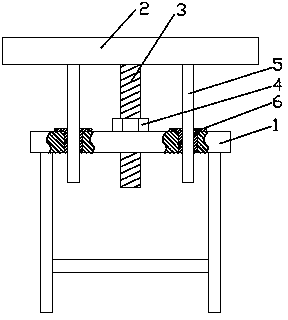

[0010] figure 1 It shows the steel jacking conveying device provided by the present invention, which includes a support base 1, a jacking platform 2, and a screw 3. One end of the screw 3 is fixedly connected to the jacking platform 2, and the other end is sleeved with a nut 4 and connected to the support base 1. Threaded connection; the support seat 1 is provided with two guide holes, and a bush 6 is arranged in the guide hole; the jacking platform 2 is connected with two guide rods 5 extending into the bush 6 respectively.

[0011] In order to make the lifting of the jacking platform 2 smoother, two guide rods 5 are symmetrically distributed on both sides of the screw rod 3 to make it evenly stressed. Ribs are arranged symmetrically on both sides of the jacking platform 2 to prevent the steel from skewing and fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com