A sugar grabbing manipulator structure of a high-speed double-twist packaging machine

A twist-packing and manipulator technology, applied in the field of sugar grabbing manipulator structure, can solve the problem of not finding the same or similar technical solutions, and achieve the effect of improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

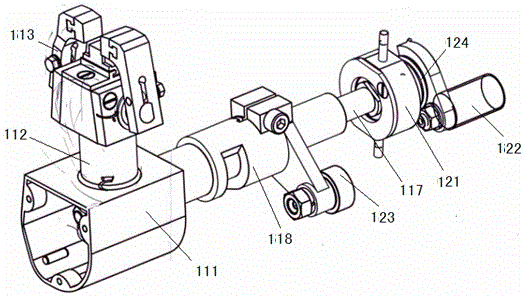

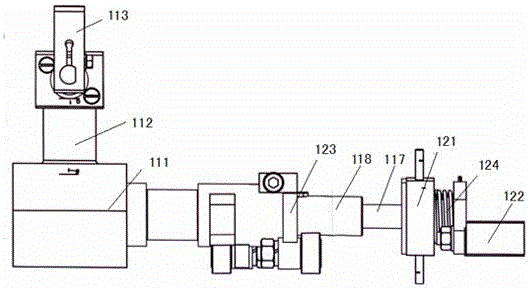

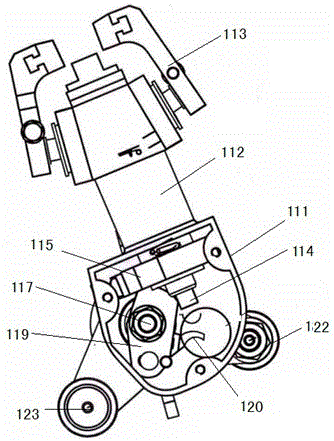

[0014] Such as Figure 1-3 As shown, the present invention discloses a sugar gripping manipulator of a high-speed double-twist packaging machine, which includes a base 111, a rotatable jaw mounting column 112 installed on the base 111, and a gripper installed on the top of the jaw mounting column 112. A pair of jaws 113, the middle part of the jaws 113 is movably connected to the top of the jaw mounting column 112, and the lower end of the jaws 113 extends into the jaw mounting column 112; it also includes a clamping drive rod 114 for driving the jaws 113 to clamp , the clamping driving rod 114 is built in the jaw mounting column 112 and extends along the axial direction of the jaw mounting column 112, the upper end of the clamping driving rod 114 is hinged with the lower ends of the two jaws 113 at the same time, and the lower end is sleeved with an eccentric wheel 115, The clamping driving rod 114 is also equipped with a return spring for limiting the position of an eccentri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com