Orchard ditcher

A trencher and orchard technology, which is applied in the directions of excavating/covering trenches, planting methods, and applications, can solve the problems of limited working space in vineyards, limitations of large trenchers, and large volume of high-horsepower tractors. Small, save energy, increase the effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the application according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. . In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

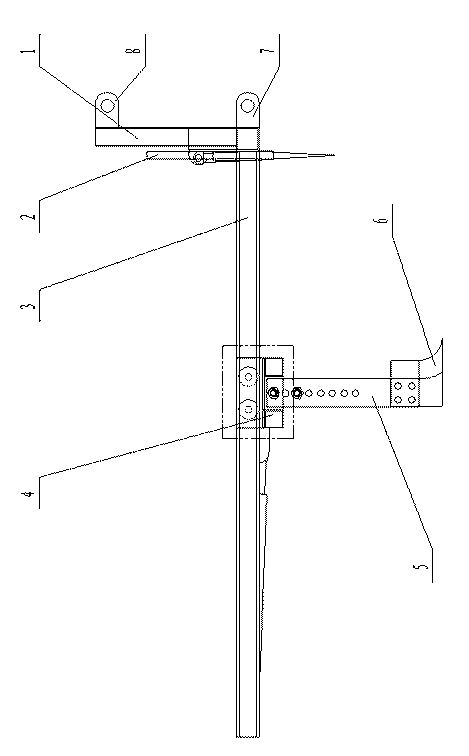

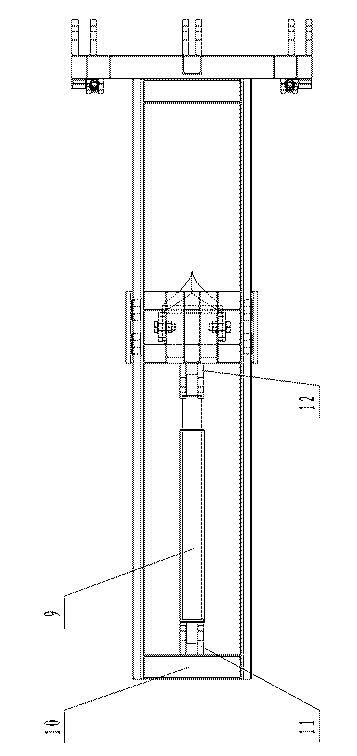

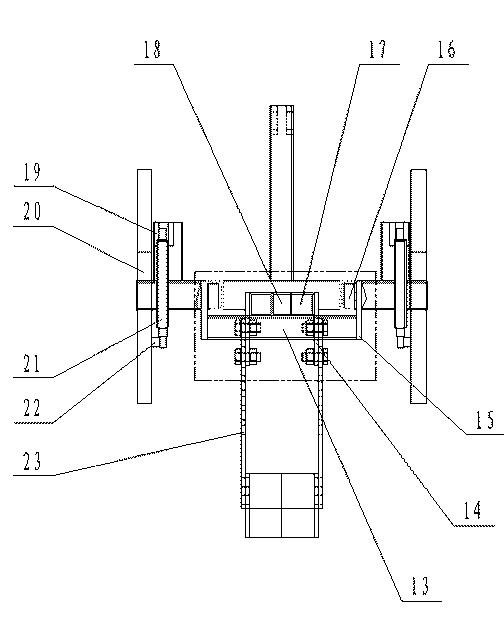

[0018] refer to figure 1 — image 3 , the embodiment of the present invention is an orchard ditching machine, which is characterized in that it includes a traction frame 1, and the traction frame 1 is provided with a guide rail 3 and a resistance plate guide tube 20, and the sliding device 4 slides on the guide rail 3. The sliding device 4 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com