Exhauster tail pipe pulling mechanism for machining bulb of road motor vehicle

A technology for motor vehicles and exhaust machines, applied in the direction of electric tube/lamp exhaust, etc., can solve the problems of low production efficiency, inability to meet modern production, poor product consistency, etc., to improve exhaust quality, reduce power consumption, and save energy. Operator effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

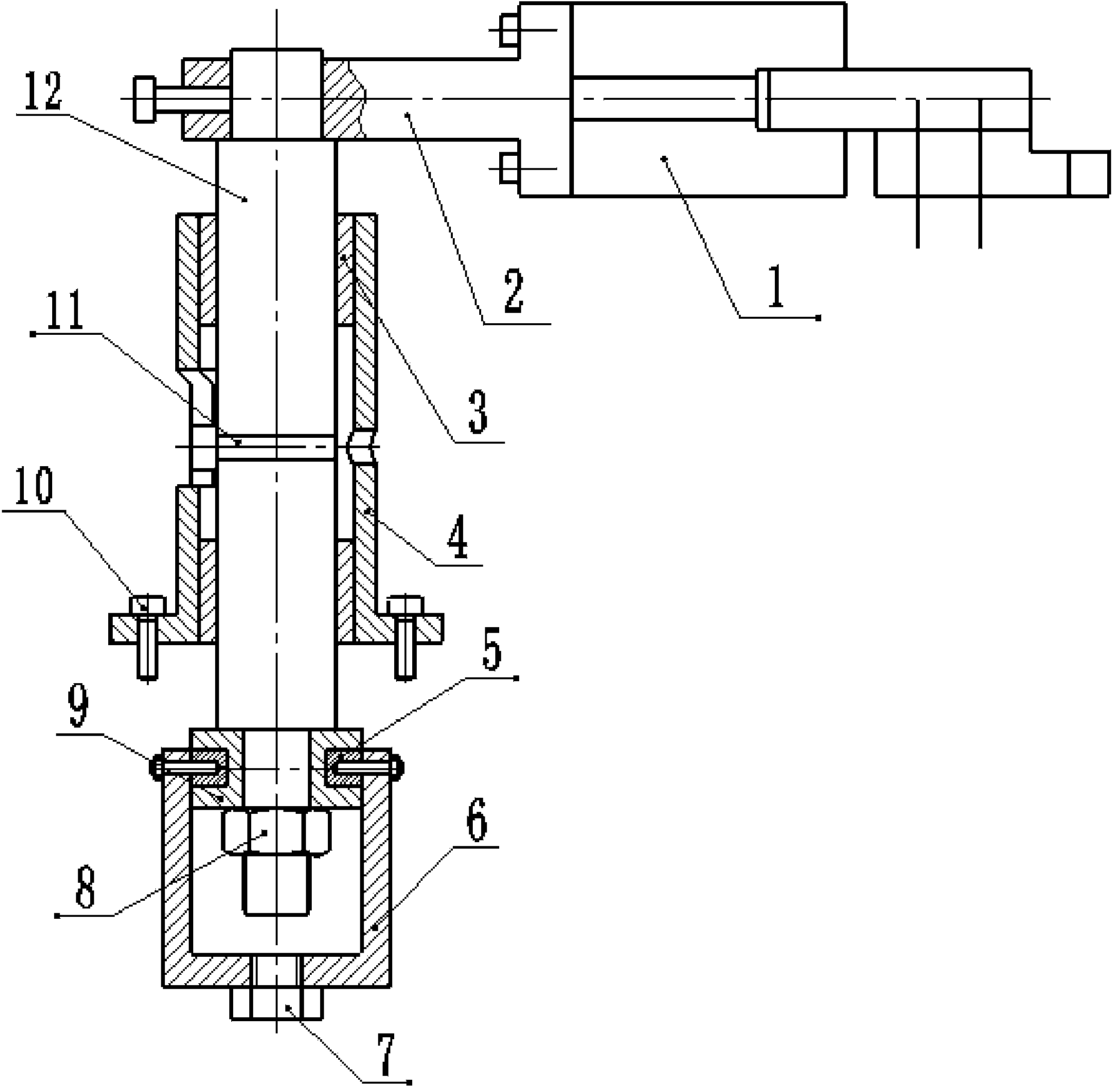

[0011] The main contents of the system are: including clamping exhaust cylinder 1, cylinder bracket 2, bearing bush 3, support 4, liquid shaft 5, connecting sleeve 6, plug 7, nut 8, bracket sleeve 9, screw 10, pin shaft 11 and The rotating shaft 12 is characterized in that the clamping exhaust cylinder 1 is fixedly installed on the cylinder bracket 2 by bolts, the cylinder bracket 2 is installed on the top of the rotating shaft 12 and is compressed by screws 10 in the radial direction, and the left end of the cylinder bracket 2 is horizontally Both the inner hole and the vertical direction are processed with inner holes, the inner hole of the support 4 is installed on the rotating shaft 12, the upper and lower ends of the inner hole of the support 4 are installed with bearing bushes 3, and the middle part of the support 4 is radially processed. groove, the pin shaft 11 is installed in the guide groove and penetrates into the radial inner hole of the rotating shaft 12, the boss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com