High pressure, constant pressure two-stage rubber membrane sealed gas cabinet

A two-stage, rubber-membrane technology, which is applied in the field of two-stage rubber-membrane-sealed gas cabinets, high-pressure rubber-membrane-sealed gas cabinets, and dry-type rubber-membrane-sealed gas cabinets. The cabinet space can not be effectively used and other problems, to achieve the effect of simplifying installation and maintenance operations, safe and simple construction and maintenance, and reducing the probability of gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

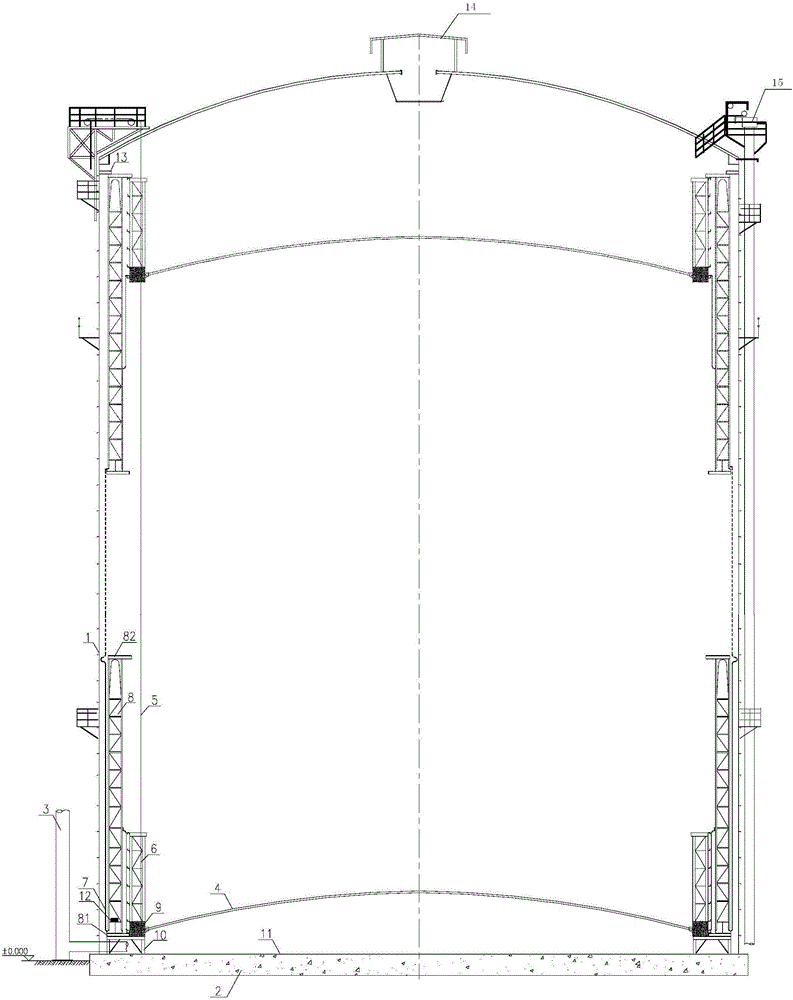

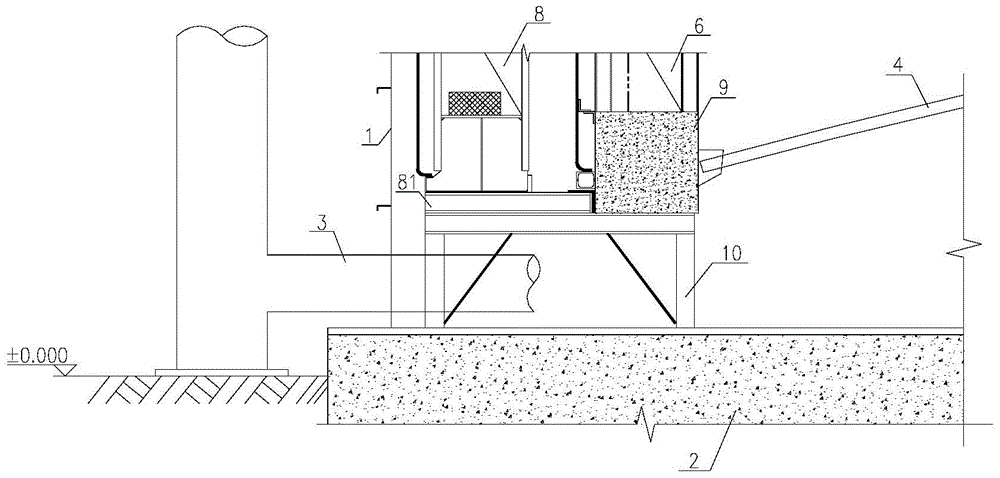

[0027] The high-pressure and constant-pressure two-stage rubber membrane sealed gas cabinet of this embodiment includes a cabinet body, a T fence 8 that can be raised and lowered along the inside of the cabinet, a piston device that can be raised and lowered along the inner side of the T fence, and the piston device is connected to the T fence respectively Sealing rubber film 7 for sealing at the junction of the T fence and the cabinet body;

[0028] The rubber sealing film includes a first rubber sealing film arranged between the inner side of the T fence and the piston fence and a second rubber sealing film arranged between the outer side of the T fence and the cabinet;

[0029] The cabinet body includes a vertical column supporting the cabinet body itself, a gas cabinet bottom plate 11, and the gas cabinet bottom plate is a horizontal steel plate, the gas cabinet bottom plate is set on the gas cabinet foundation 2, and the gas cabinet foundation is also horizontal;

[0030] The T ...

Embodiment 2

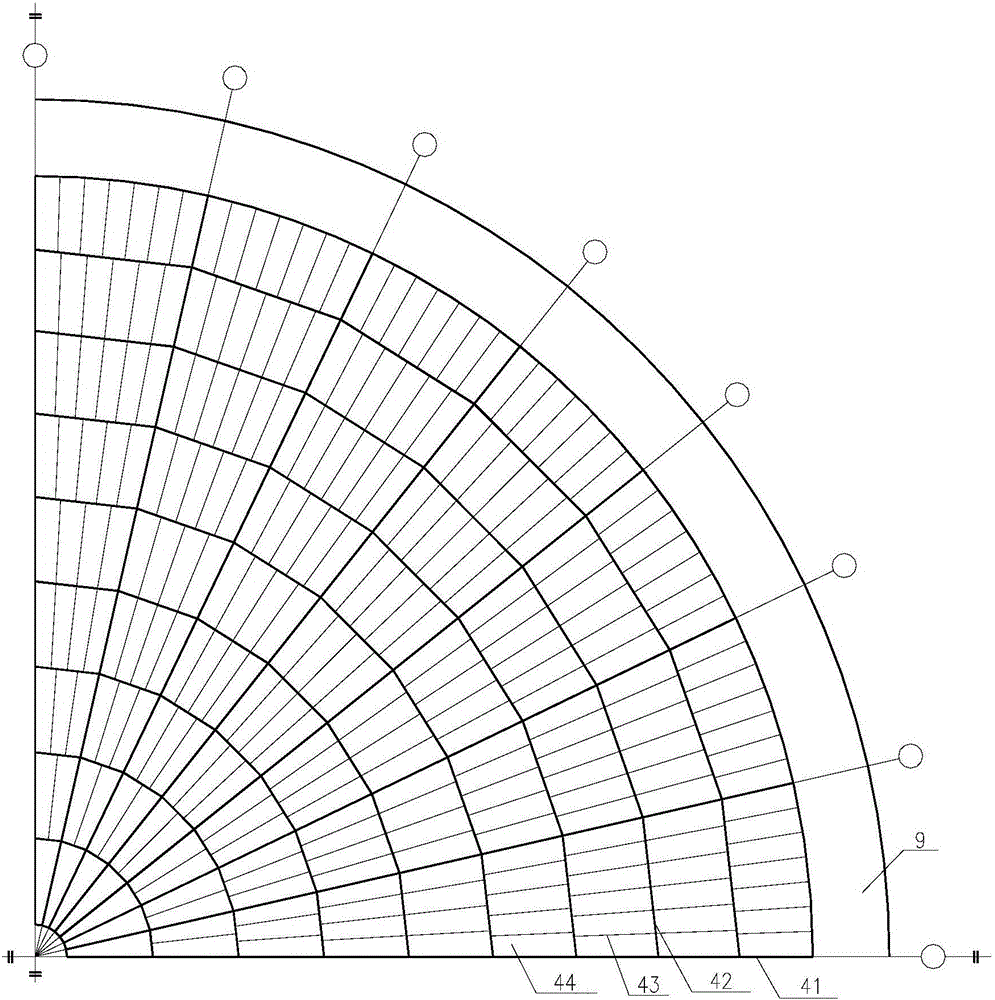

[0044] Such as figure 2 The structure of this embodiment is similar to that of embodiment 1, except that the piston bottom shell is a multi-ribbed single-layer spherical reticulated shell, including a radial main beam 41 and a circumferential main beam forming a radial warp and weft structure 42. The secondary beam 43 radially penetrates the hoop main beam, and the piston bottom plate 44 that overlaps the radial main beam and the hoop main beam or between the secondary beam and the hoop main beam.

[0045] The piston bottom shell of this structure has the advantages of high structural strength and stable support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com