Mating rotary disc of rock core drill

A core drilling rig and turntable technology, applied in the field of geological exploration, can solve the problems of small torsion force and inability to use foundation pile holes for construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

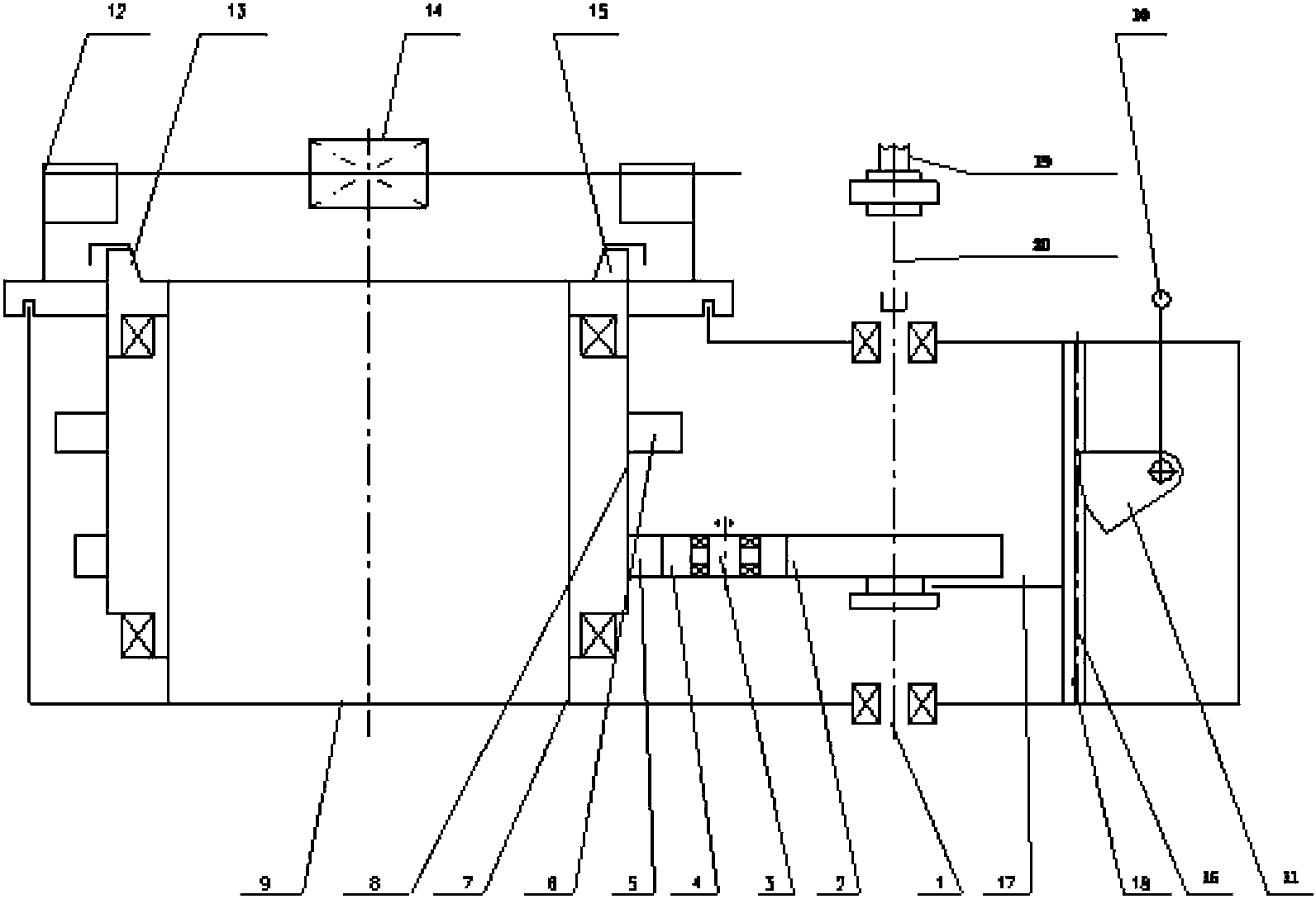

[0012] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0013] As shown in the figure, the casing 9 of the present invention is provided with the input shaft 1 matched with the core drilling machine in the casing, and the driving gear 2 that slides up and down on the input shaft is sleeved. Sliding forward and reverse operation mechanism, when the driving gear slides to the bottom, the intermediate gear 4 set on the intermediate shaft 3 meshes with the driving gear and the counter gear 6 meshes with the driving gear when the driving gear slides to the top. The intermediate gear meshes with the forward gear 5, the forward gear and the reverse gear are set on the hollow shaft 7, the upper end of the hollow shaft is provided with a turntable 8 which rotates synchronously with it,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com