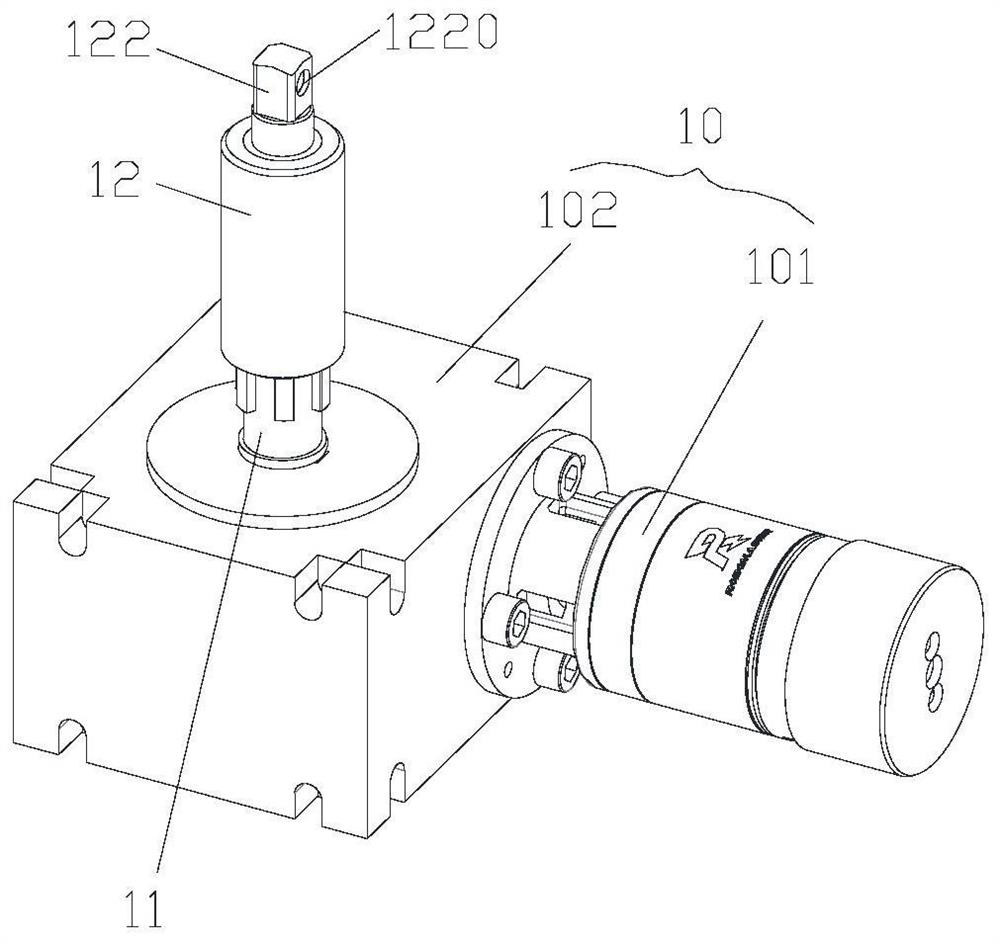

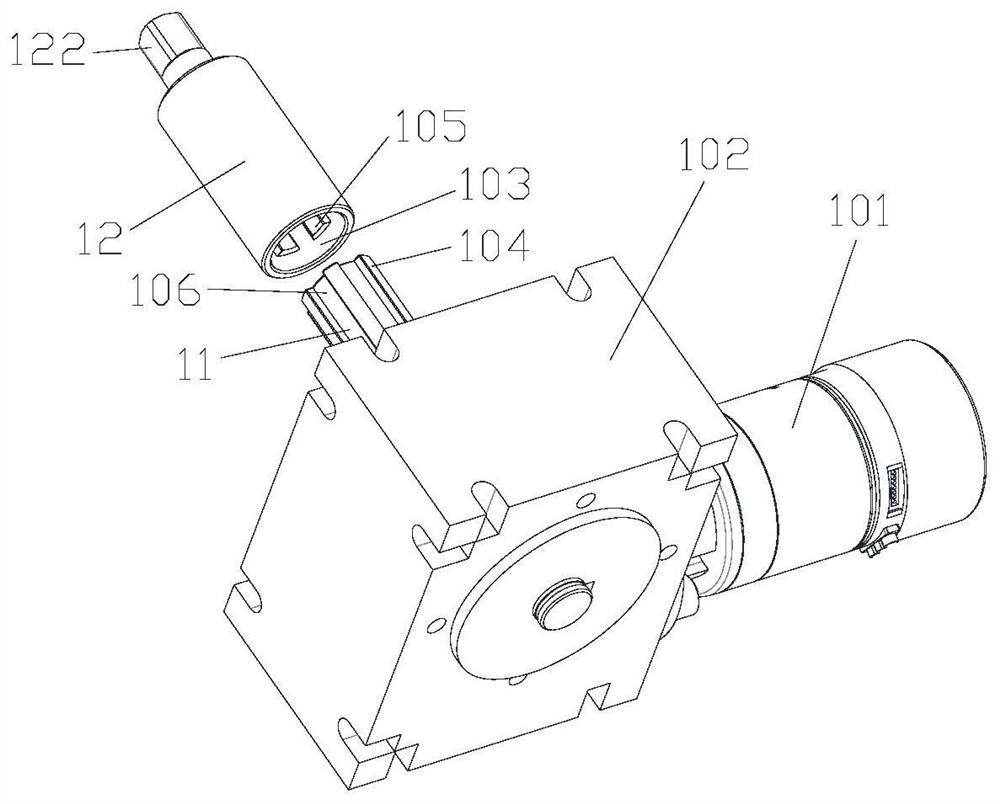

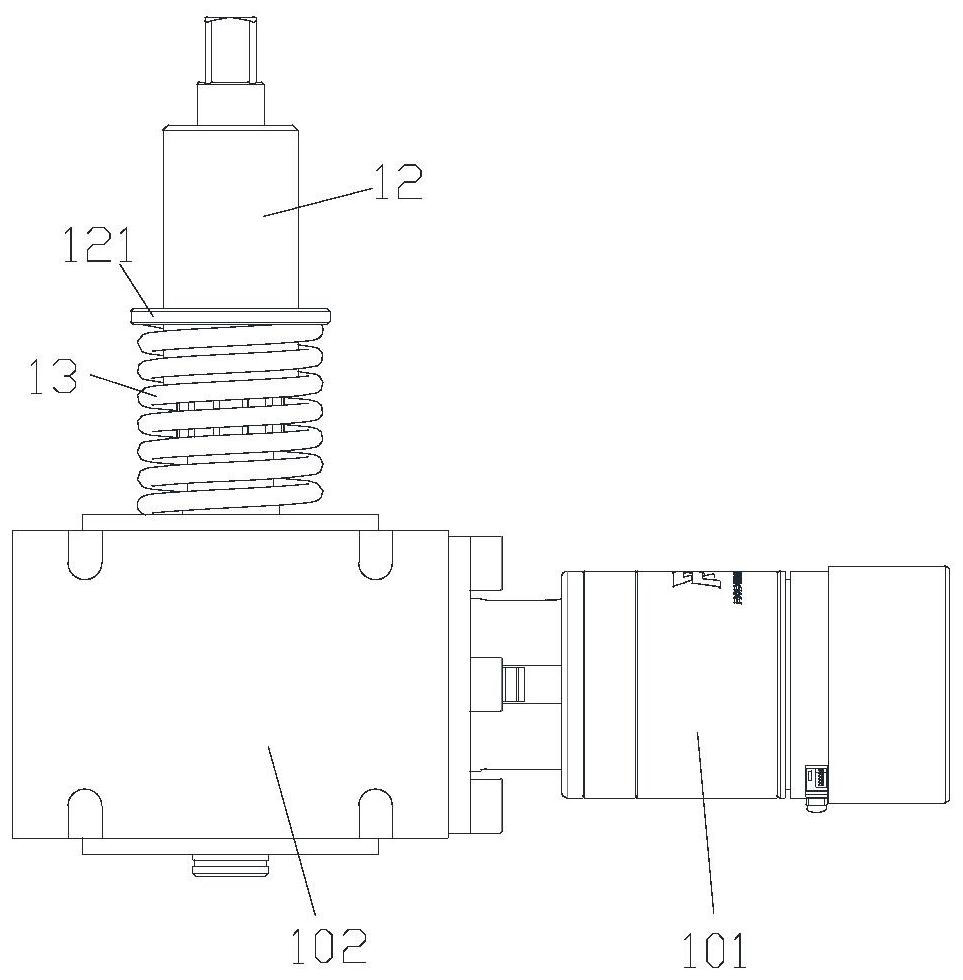

A manipulator end tool

A technology of end tools and manipulators, applied in the field of manipulators, can solve problems such as damage to screwed parts, and achieve the effect of reducing impulse force and high torque output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following description and drawings illustrate specific embodiments of the invention sufficiently to enable those skilled in the art to practice them. Portions and features of some embodiments may be included in or substituted for those of other embodiments. The scope of embodiments of the present invention includes the full scope of the claims, and all available equivalents of the claims. Herein, relational terms such as first and second etc. are used only to distinguish one entity or structure from another without requiring or implying any actual relationship or relationship between these entities or structures. order. Various embodiments herein are described in a progressive manner, each embodiment focuses on the differences from other embodiments, and the same and similar parts of the various embodiments may be referred to each other.

[0037] In describing the present invention, it should be understood that the terms "longitudinal", "transverse", "upper", "low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com