High-pressure diaphragm filter plate

A high-pressure diaphragm and diaphragm plate technology, which is applied in the direction of filtration and separation, special treatment targets, water/sludge/sewage treatment, etc., can solve the problems of low tympanic membrane pressure, difficult maintenance, low pressure resistance, etc., and achieve strong dehydration ability and structure Simple, reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below through specific embodiments.

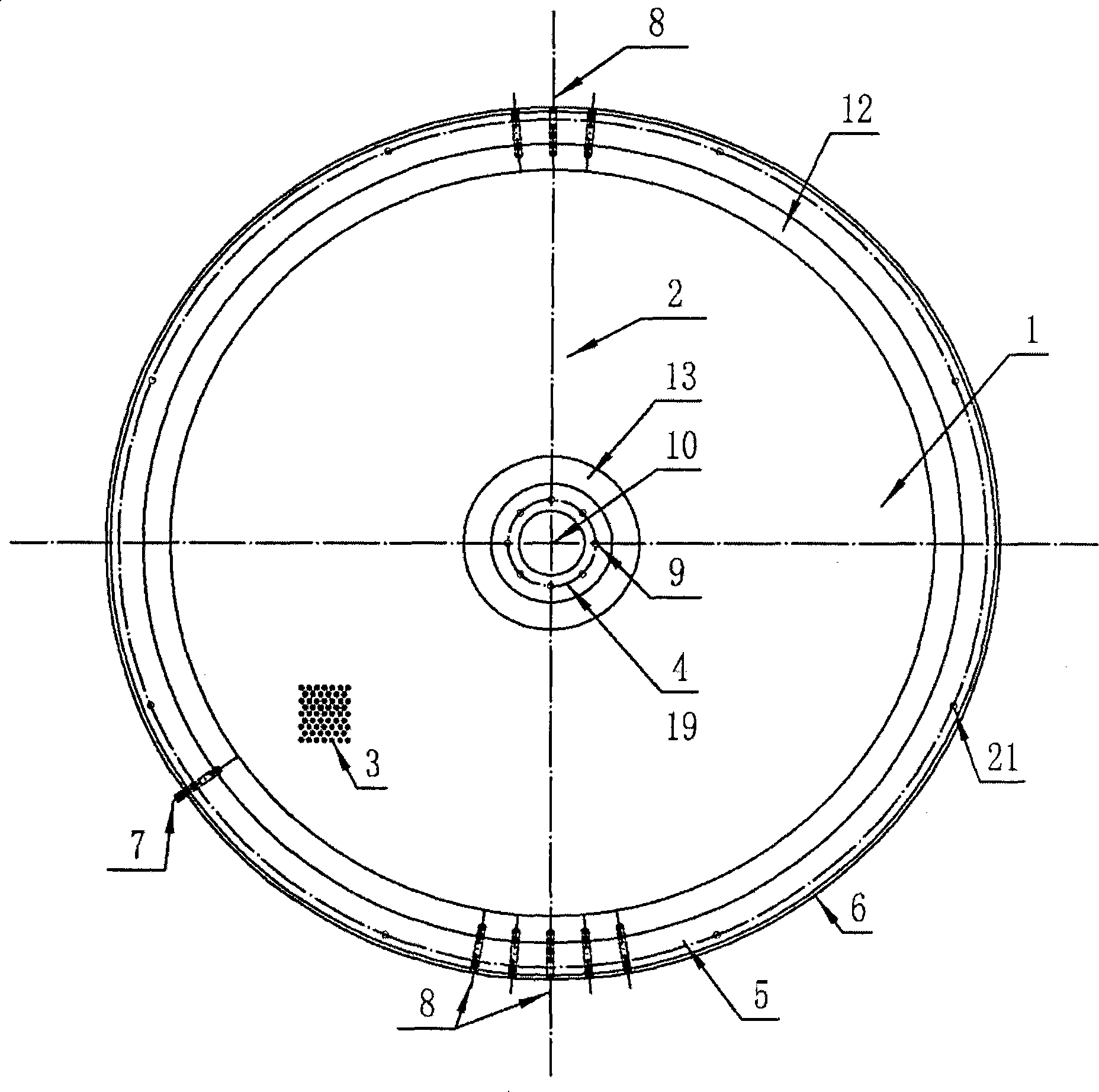

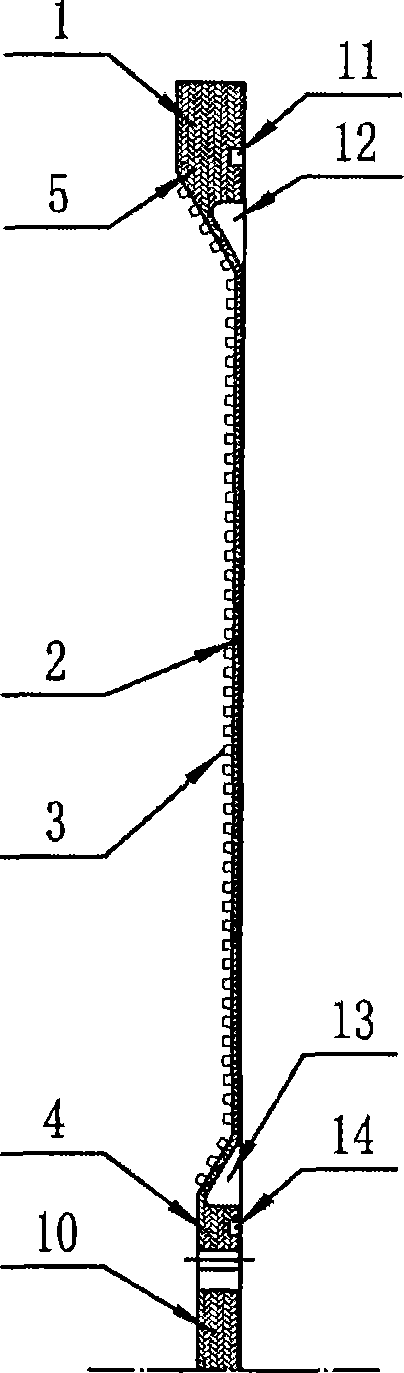

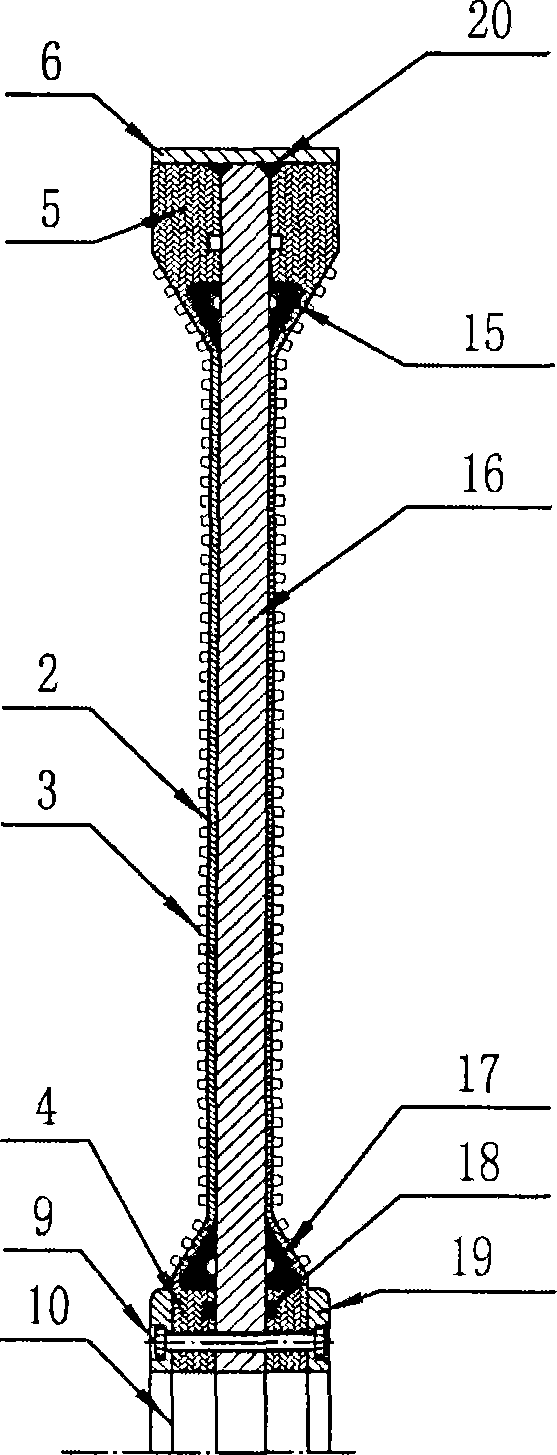

[0021] A new type of high-pressure diaphragm filter plate, consisting of two diaphragm plates 1, an intermediate support plate 16, a filter plate ring hoop 6, two inner ring sealing flanges 19, two inner ring sealing rings 18, and multiple inner ring seals Bolt 9, two filler rings 17 for inner ring deformation zone, two filler rings 15 for outer ring deformation zone, etc. Diaphragm plate 1 is circular, made of polypropylene, polyethylene or ultra-high molecular weight polyethylene by injection molding, the outermost diaphragm outer ring 5, the center of the diaphragm inner ring 4, the diaphragm movable plate 2, the diaphragm movable plate 2. The diaphragm outer ring deformation bend 12 is connected to the diaphragm outer ring 5, and the diaphragm inner ring deformation bend 13 is connected to the diaphragm inner ring 4. The thickness of the diaphragm inner r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com