Discharging pot for powder and particle materials

A material and powder technology, which is applied in the field of powder material unloading tanks, can solve the problems of difficulty in production, increase the speed of the engine to the air compressor, and increase exhaust gas emissions, so as to improve the safety and stability of transportation, unloading, etc. The effect of shortening the material running time and reducing the damage of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

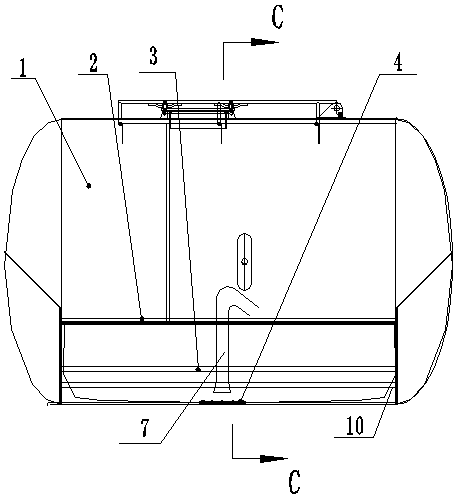

[0037] refer to image 3 , 6 , 7, a discharge tank for powder materials, comprising a tank body 1 and a discharge pipe 7, the bottom of the inner wall of the tank is longitudinally provided with several vent pipes 3, and several vent holes are arranged on the vent pipe 3 , the tank body is provided with an air inlet connected to the ventilation pipe; a fluidized cloth 10 is also fixed around the lower part of the inner wall of the tank, and the surroundings of the fluidized cloth 10 are sealed with the inner wall of the tank body 1, and the central part of the fluidized cloth 10 It is fixed with the center of the bottom of the tank through the flange 4, and the central part of the fluidized cloth 10 has a ventilating area, and the vent pipe 3 is located between the inner wall of the tank and the fluidized cloth 10; the feeding port of the discharge pipe is located in the ventilated 1 to 50 cm above the area.

[0038] The inner wall of the tank is provided with slots 2 around...

Embodiment 2

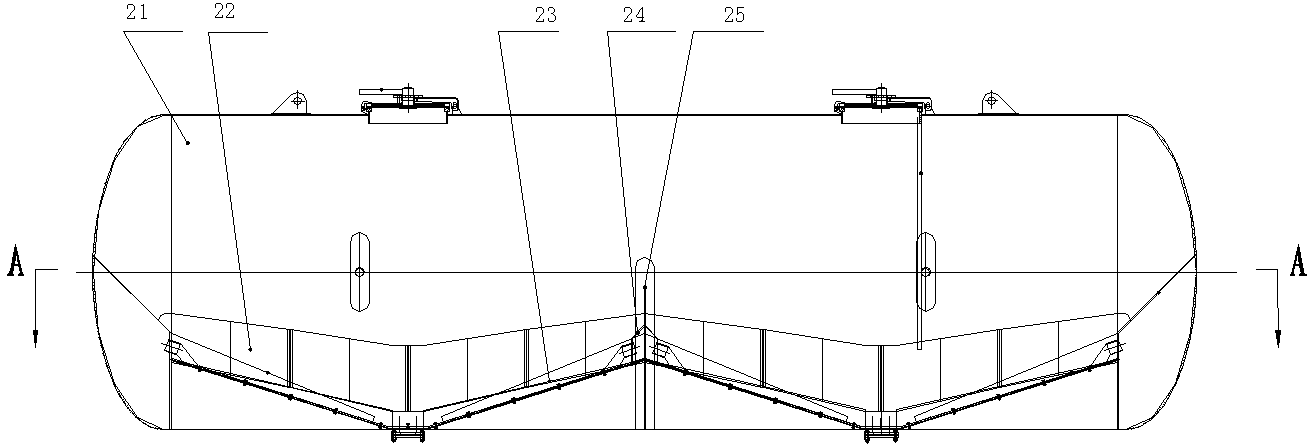

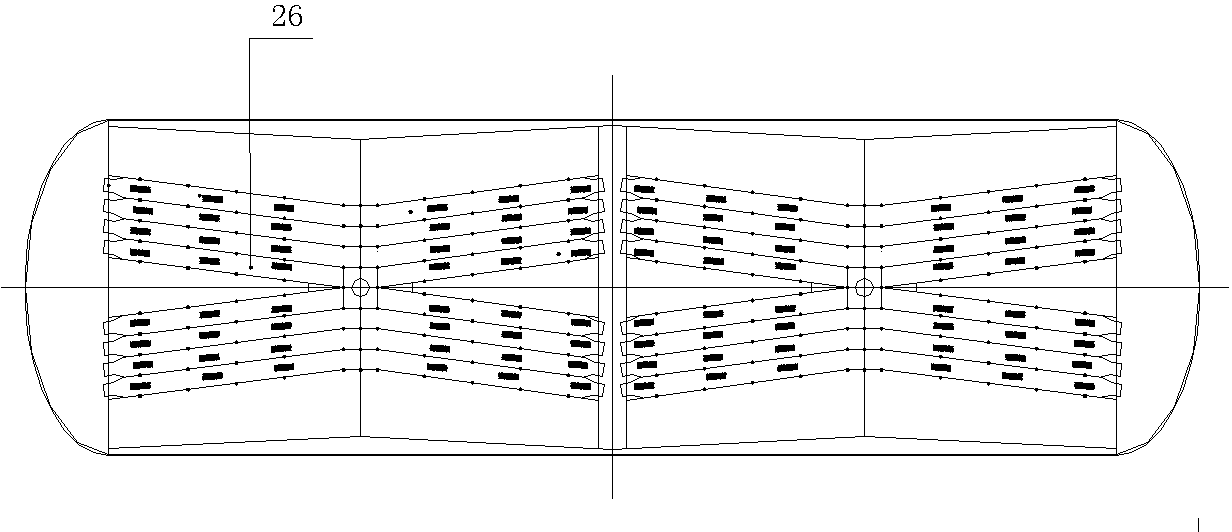

[0044] refer to Figure 4-9 , a discharge tank for powder materials, comprising a tank body 1 and a discharge pipe 7, the bottom of the inner wall of the tank is longitudinally provided with several vent pipes 3, and several vent holes are opened on the vent pipe 3, the tank The body is provided with an air inlet communicated with the ventilation pipe.

[0045] The lower part of the tank body is divided into three compartments by two compartment plates 6, and fluidized cloth 10 is fixed around the lower part of the inner wall of each compartment. The center of the 10 and the center of the bottom of the sub-bin are fixed by the flange 4, and the central part of the fluidized cloth 10 has a ventilating area 5, and the ventilating pipe 3 is located between the inner wall of the tank and the fluidized cloth 10; the inlet of the discharge pipe 7 The feed port is located 1-50cm above the air-permeable area.

[0046] The inner wall of the tank is provided with slots 2 around, the f...

Embodiment 3

[0053] refer to Figure 10 , different from Example 2, the present embodiment is provided with an air bag 9 at both ends of the sub-bin on the right, the air bag 9 is located between the inner wall of the sub-bin and the fluidized cloth 10, the air bag 9 has a certain degree of air permeability, Air bag 9 sets up independent air intake pipeline and valve. The size of the gas bag can be cylindrical with a diameter of 400-700mm and a length of 1000-1500mm. When cleaning the remaining material, turn on the air inlet switch of the air bag, and the air bag will start to inflate, and the bulging angle of the fluidized cloth at both ends of the sub-bin will increase, which will increase the fluidization degree of the material, and achieve a better effect of unloading and clearing the warehouse. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Mass per unit area | aaaaa | aaaaa |

| Mass per unit area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com