Double-side printing parameter generation method, double-side printing method, device and system

一种双面印刷、正面印刷的技术,应用在印刷领域,能够解决印刷参数不合理等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

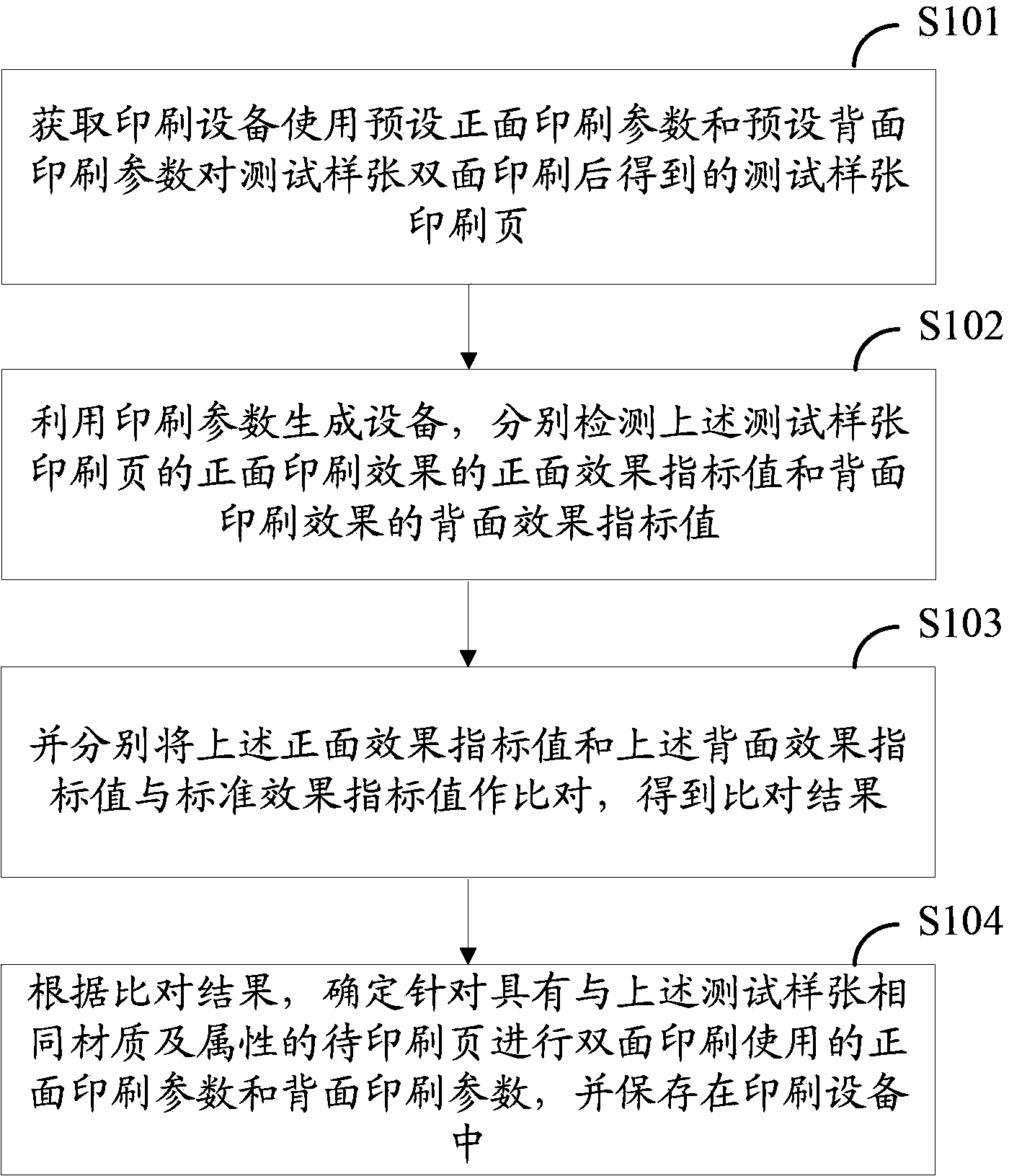

[0071] Corresponding to one of the methods for generating double-sided printing parameters provided in the embodiments of the present invention, Embodiment 1 of the present invention provides a method for generating double-sided printing parameters, such as Figure 4 As shown, specific steps may include:

[0072] S401. Obtain the printed page of the test sample obtained after the printing device double-sidedly prints the test sample by using the preset front printing parameters and the preset back printing parameters.

[0073] In this step, the printing device can use the preset front printing parameters and the preset back printing parameters to print the specified pattern on the test sample, and obtain the test sample printed page with the specified pattern printed on both sides, wherein the preset front printing parameters and the preset The backside printing parameters are the same.

[0074] S402. Use the printing parameter generation device to respectively detect the col...

Embodiment 2

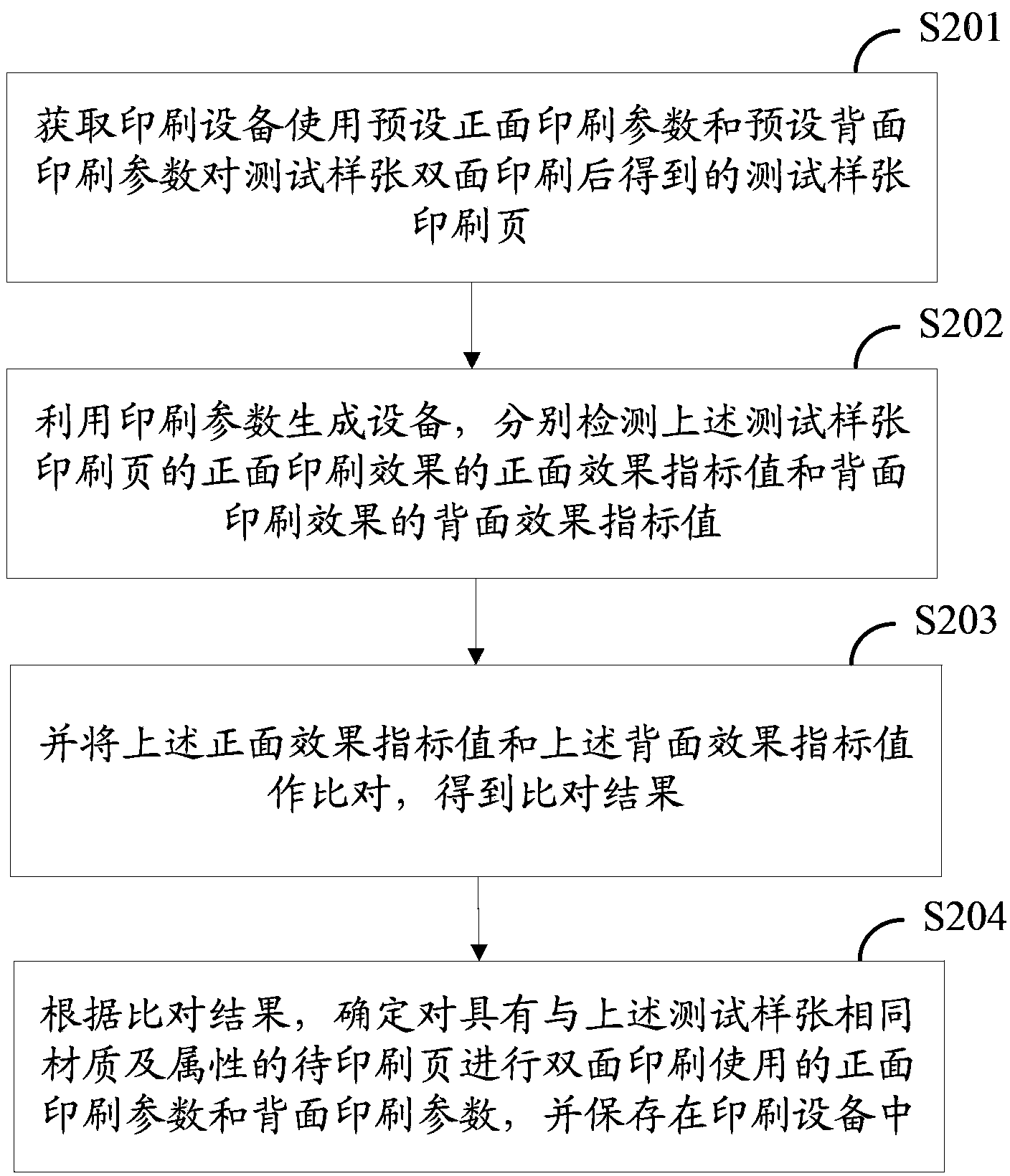

[0081] Corresponding to one of the double-sided printing parameter generation methods provided in the embodiment of the present invention, embodiment 2 of the present invention provides a double-sided printing parameter generation method, such as Figure 5 As shown, specific steps may include:

[0082] S501. Obtain a printed page of the test sample obtained after the printing device double-sidedly prints the test sample using preset front printing parameters and preset back printing parameters.

[0083] S502. Using the printing parameter generation device, respectively detect the front scaling ratio and the rear scaling ratio of the printed page of the test sample.

[0084] In this step, the printing parameter generation device is used to respectively detect the scaling ratios of the specified patterns printed on the front and back of the test sample printed with the specified pattern. The scaling ratio may be the ratio of the printed specified pattern to the printed page, or...

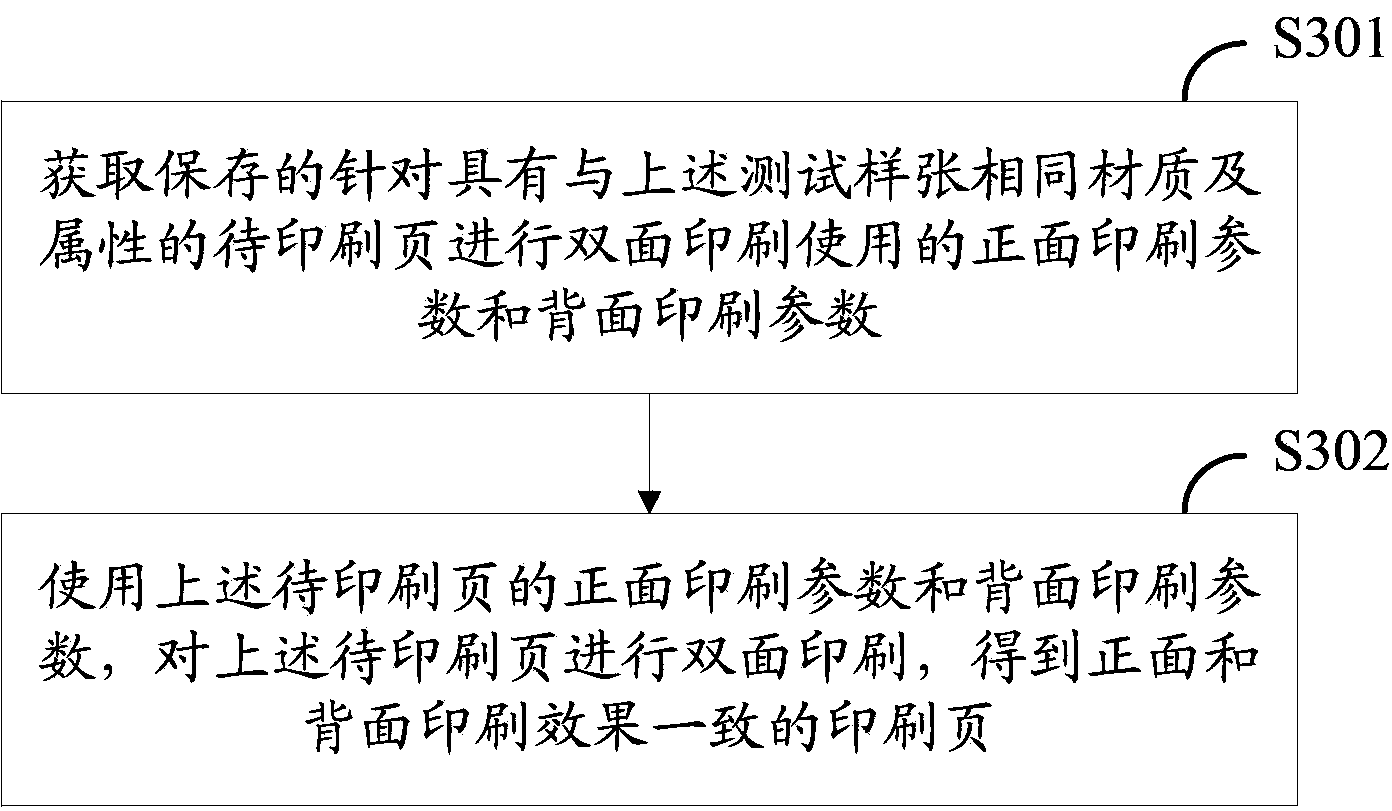

Embodiment 3

[0091] Corresponding to the second method for generating double-sided printing parameters provided by the embodiment of the present invention, embodiment 3 of the present invention provides a method for generating double-sided printing parameters, such as Figure 6 As shown, specific steps may include:

[0092] S601. Obtain the printed page of the test sample obtained after the printing device double-sidedly prints the test sample by using the preset front printing parameters and the preset back printing parameters.

[0093] S602. Use the printing parameter generation device to respectively detect the color composition of the front side and the color composition of the back side of the printed page of the test sample.

[0094] S603. Use the above front color composition as a standard color composition, and proceed to step S604; otherwise, proceed to step S607.

[0095] S604. Comparing the above-mentioned back color composition with the standard color composition to obtain a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com